Ama-Conveyors Amabhande

Isingeniso

Lesi sihloko sizobheka kabanziamabhande okuthutha.

I-athikili izoletha ukuqonda okwengeziwe ngezihloko ezifana nalezi:

- Ama-Belt Conveyors kanye Nezingxenye zawo

- Izinhlobo zama-Belt Conveyors

- Ukuklama kanye Nokukhethwa Kwezithuthi Zebhande

- Izicelo kanye Izinzuzo Amabhande Conveyors

- Nokunye Okuningi...

Isahluko 1: Ama-Belt Conveyors kanye Nezingxenye zawo

Lesi sahluko sizoxoxa ngokuthi iyini i-conveyor yebhande kanye nezingxenye zalo.

Iyini i-Belt Conveyor?

I-belt conveyor iyisistimu eklanyelwe ukuthutha noma ukuhambisa izinto ezibonakalayo njengempahla, izimpahla, kanye nabantu ukusuka endaweni eyodwa ukuya kwenye.Ngokungafani nezinye izindlela zokudlulisa ezisebenzisa amaketango, ama-spirals, ama-hydraulics, njll., amabhande okuthutha azohambisa izinto kusetshenziswa ibhande.Kubandakanya iluphu yezinto eziguquguqukayo ezelulwe phakathi kwamarola acushwa yinjini kagesi.

Ngenxa yokuthi izinto ezithuthwayo ziyahlukahluka ngokwemvelo, okokusebenza kwebhande nakho kuyahlukahluka ngesistimu esetshenziswa kuyo. Ngokuvamile kuza njenge-polymer noma ibhande lenjoloba.

Izingxenye ze-Belt Conveyor

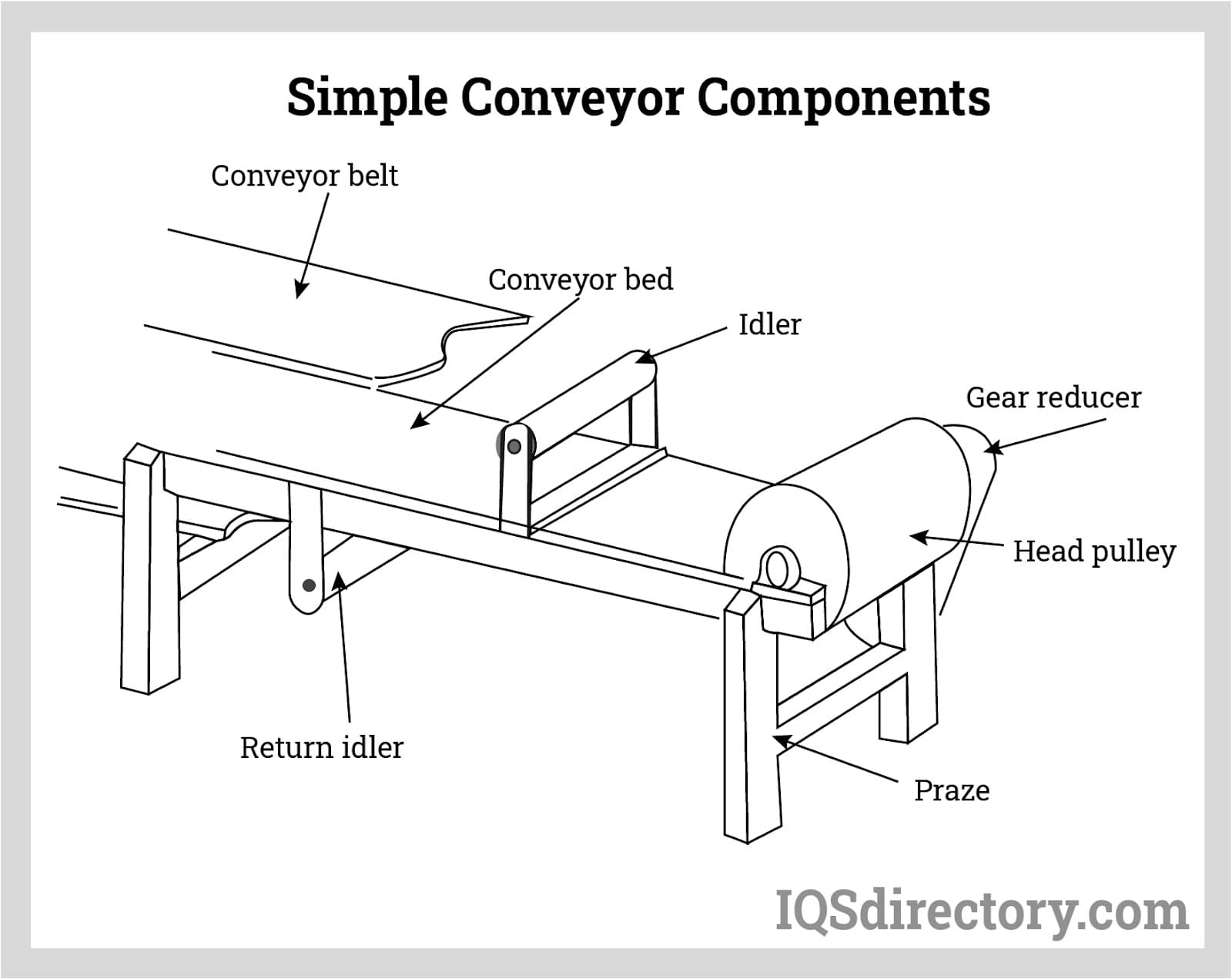

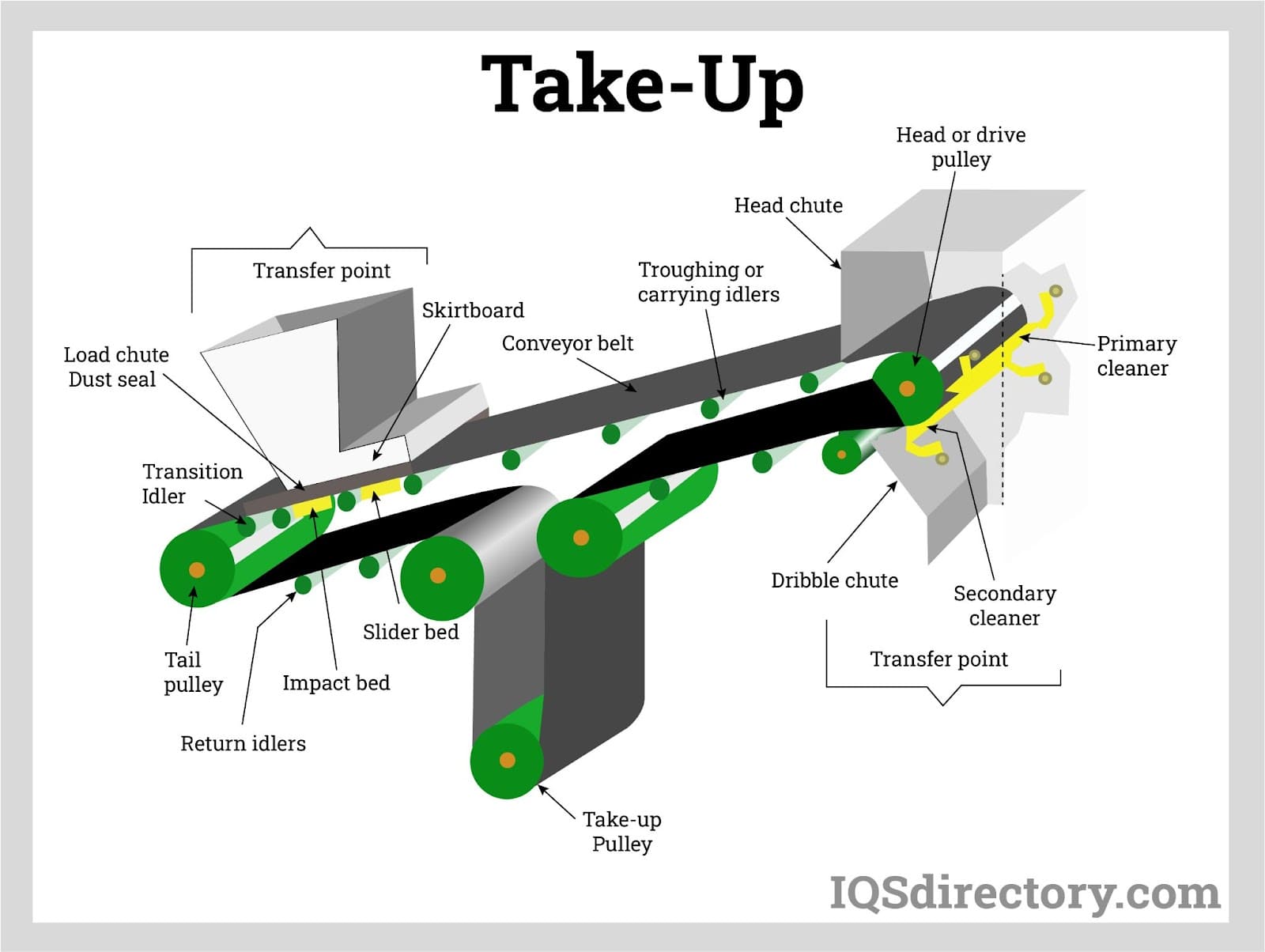

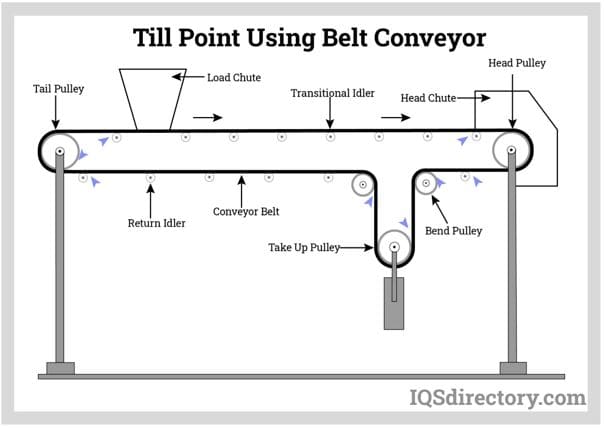

Isistimu yokuthutha ibhande elijwayelekile linepulley yekhanda, i-tail pulley, i-idler rollers, ibhande, nohlaka.

Ikhanda Pulley

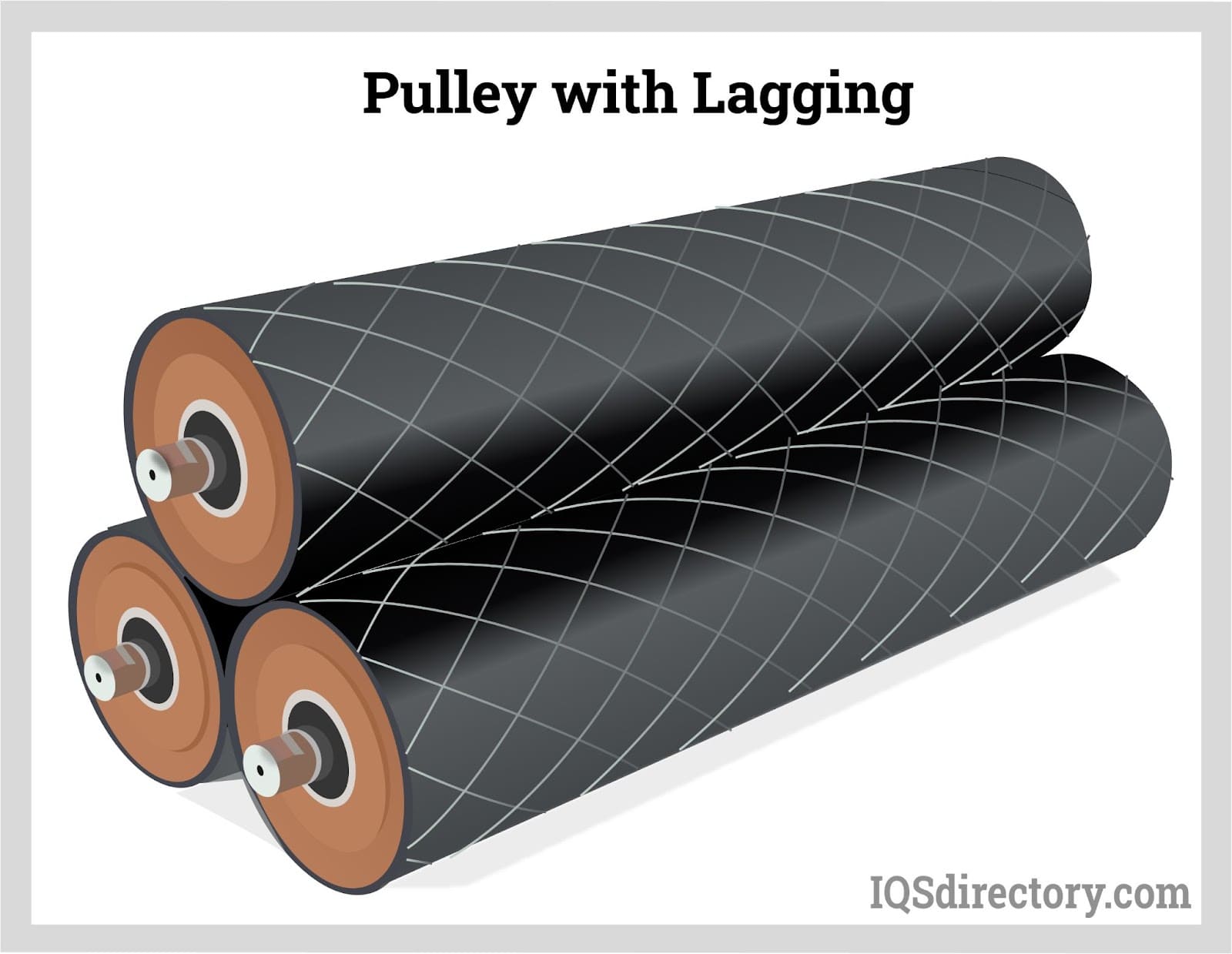

I-head pulley iyona ehlanganiswe ne-actuator kanye ne-motor kagesi.I-pulley yekhanda ishayela isihambisi, ngokuvamile sisebenza njengamandla adonsayo kunokusunduza.Ikakhulukazi itholakala endaweni lapho umthumeli wempahla ethula khona umthwalo wayo, okwaziwa ngokuthi ukuphela kokukhipha isithuthi sebhande.Ngenxa yokuthi i-pulley yekhanda ishayela lonke uhlelo, ngokuvamile kuyadingeka ukwandisa ukudonsa kwayo ngebhande, ngaleyo ndlela izoba nejazi elibi elimboza indawo yayo yangaphandle.Leli jakhethi libizwa nge-legging.Ngezansi ukuthi noma iyiphi i-pulley enejazi izobukeka kanjani.

I-pulley yekhanda ngokuvamile inobubanzi obukhulu kunawo wonke ama-pulleys.Kwesinye isikhathi isistimu ingaba namapulley amaningi asebenza njengama-drive pulleys.I-pulley ekupheleni kokukhishwa idrayivui-conveyor idlerngokuvamile enobubanzi obukhulu kakhulu futhi izokhonjwa njenge-pulley yekhanda.

Buyela noma Umsila Pulley

Lokhu kutholakala ekugcineni kokulayisha kwesithumeli sebhande.Kwesinye isikhathi kuza nokuma kwephiko ukuhlanza ibhande ngokudedela impahla iwele eceleni kumalungu asekelayo.

Kusethaphu esilula sokuhambisa ibhande, i-pulley yomsila izofakwa kumagayidi ngokuvamile afakwe ukuvumela ukushuba kwebhande.Kwezinye izinhlelo zokudlulisa amabhande njengoba sizobona, ukuqina kwebhande kushiywa kwenye i-roller ebizwa ngokuthi i-take-up roller.

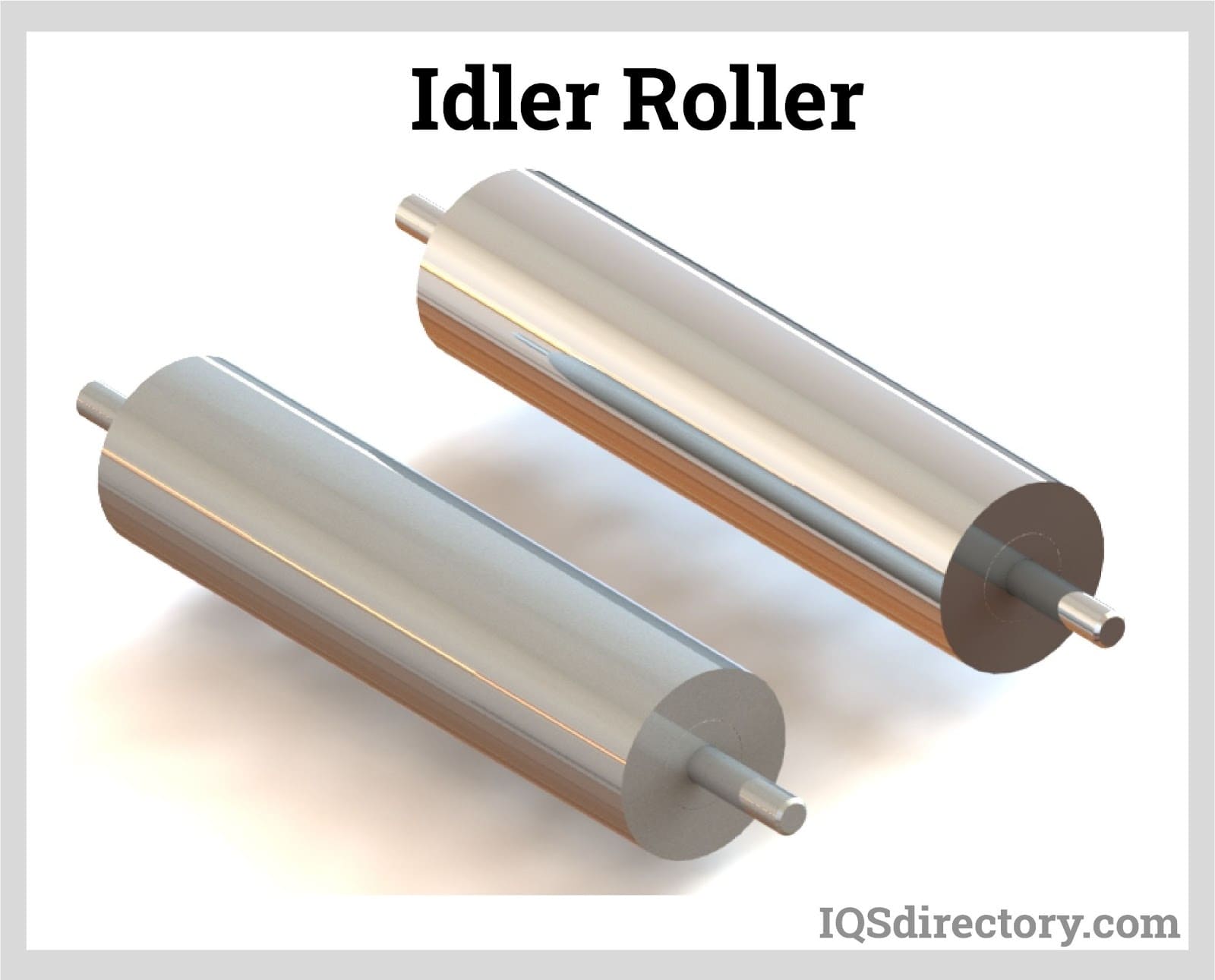

I-Idler Roller

Lawa ama-roller asetshenziswa ngobude bebhande ukusekela ibhande nomthwalo, ukuvimbela ukuhlehla, ukuqondisa ibhande, nokuhlanza i-carryback (into esele ibambelele ebhandeni).Ama-Idler roller angenza konke okungenhla noma okunye kwakho, kodwa kunoma iyiphi indawo, azohlala esebenza njengokusekela ibhande.

Kunama-rollers amaningi ahlukene emisebenzi ehlukene, njengoba ebalwe ngezansi:

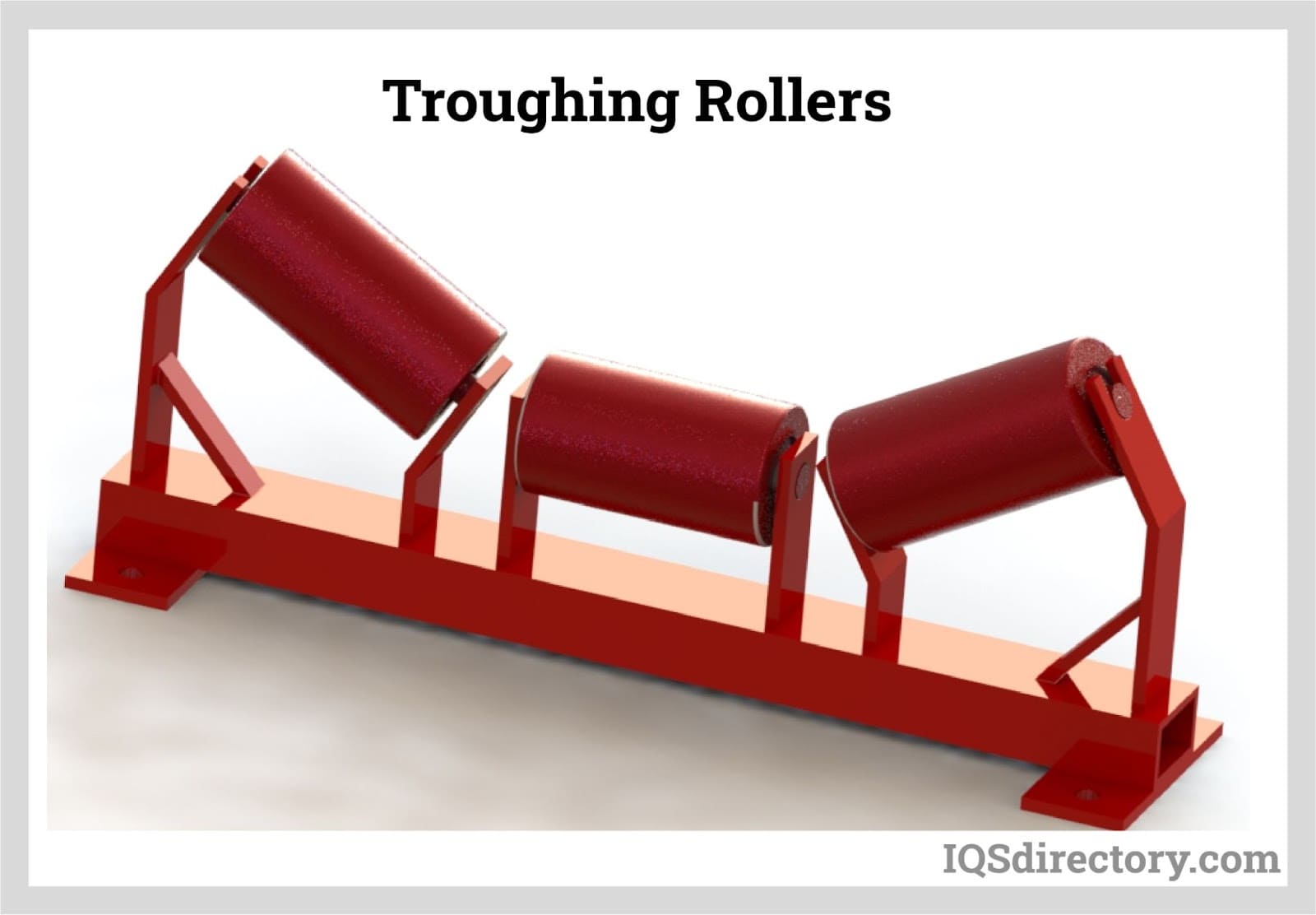

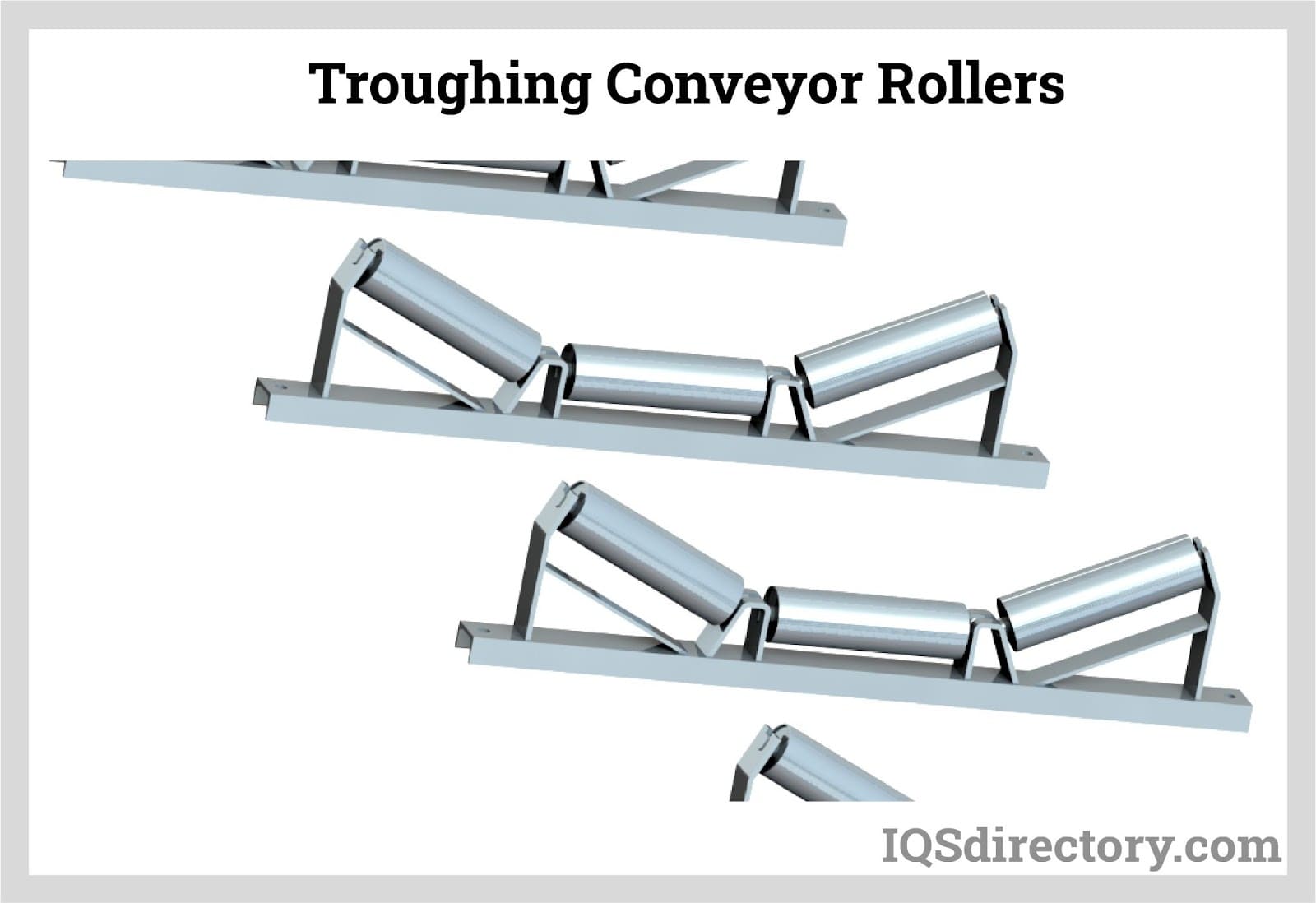

I-Troughing Idlers

Amavila abhuqayo azoba namarola amavila amathathu asethwe ekucushweni okwenza "i-trough" yebhande.Zitholakala ohlangothini oluthwala umthwalo ku-conveyor yebhande.I-idler emaphakathi ilungisiwe, futhi okubili emaphethelweni akwazi ukulungiswa.Lokhu kwenzelwa ukuthi i-engeli nokujula kwe-trough kungahlukahluka.

Lawa mavila, uma eqashiwe, azonciphisa ukuchitheka kwamanzi futhi agcine indawo enqamulayo ehlala njalo ngobude besithumeli sebhande.Ukugcina indawo enqamulayo ehlala njalo kubalulekile ekuzinzeni.

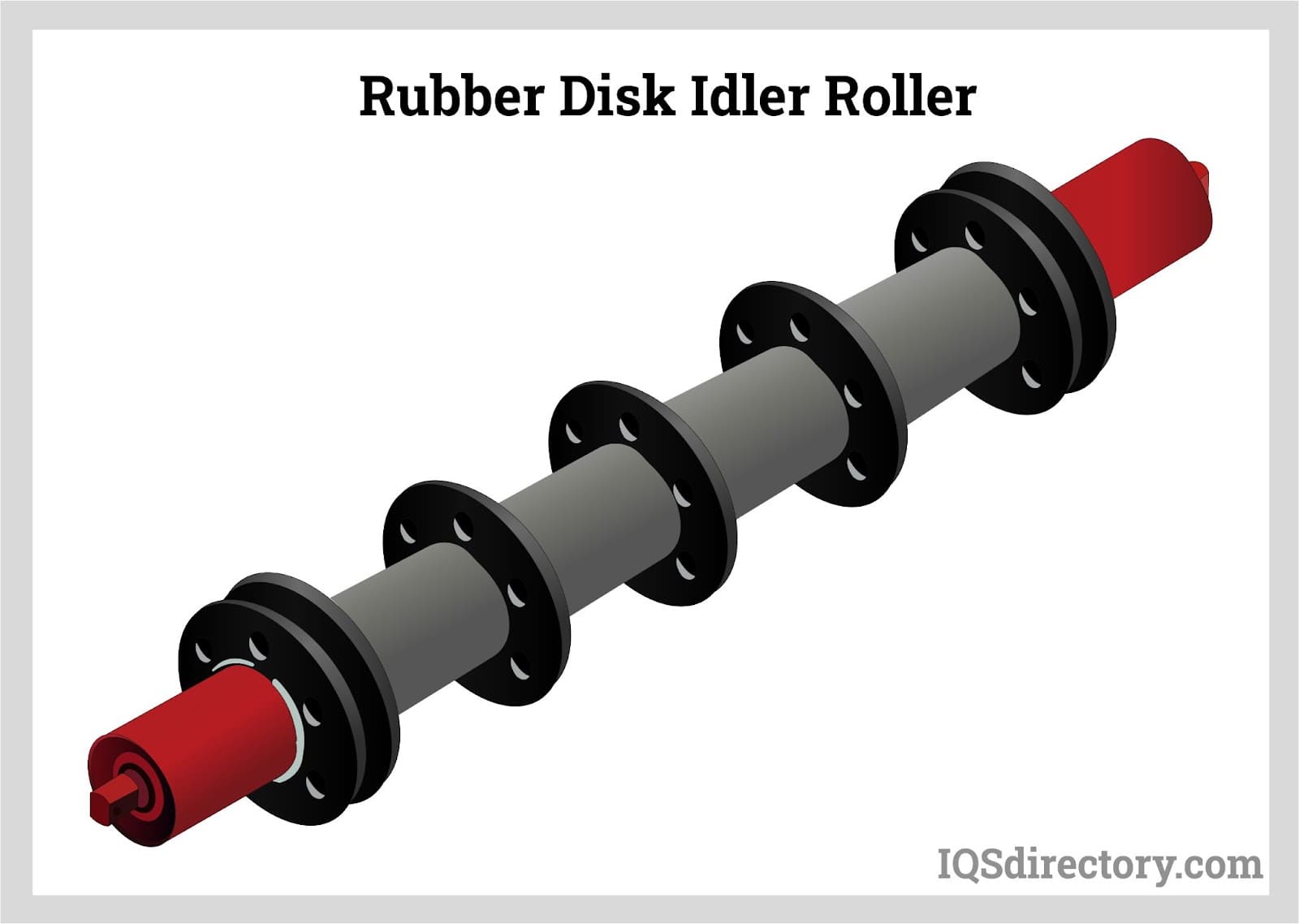

I-Rubber Disk Idler

Le idler inamadiski erabha abekwe ebangeni elimisiwe eduze kwe-eksisi yerola.Emaphethelweni okwedlulele, ama-roller asondelene kakhulu ukuze akwazi ukusekela umkhawulo webhande, ojwayele ukudabula.Amadiski ahlukanisiwe azonqamula noma iyiphi into exhunyiwe yokuthwala/esele futhi anciphise ukwakhiwa okungaphansi kwebhande.Lesi yisizathu esivamile sokungahambi kahle (lapho ibhande lishintsha ohlangothini olulodwa lwesistimu futhi libangele ukungahambi kahle).

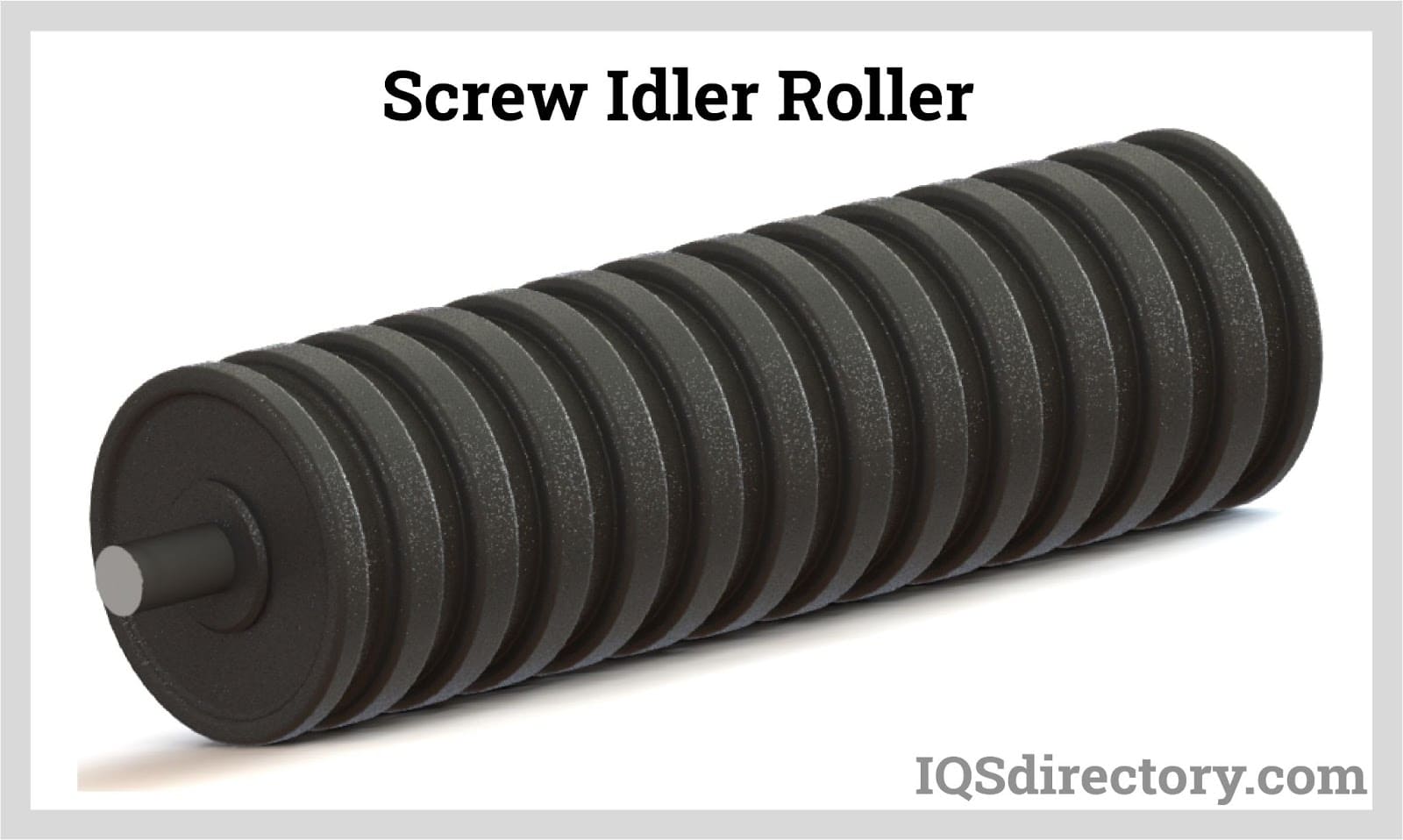

Kwesinye isikhathi amadiski ane-helical njengesikulufu futhi i-idler izobizwa ngokuthi i-rubber screw idler roller.Umsebenzi uzohlala unjalo.Isibonelo serola ye-screw idler siboniswa ngezansi.

I-screw idler nayo ingenziwa nge-rubber helix.Ama-screw idlers avame kakhulu lapho i-scrapper ekhumula i-carryback ingeke isebenze, ikakhulukazi kuma-conveyor amabhande eselula.

Umqeqeshi u-Idler

Amavila abaqeqeshi agcina ibhande ligijima liqondile.Isebenza ngokumelene nokukhohlisa.Ifinyelela lokhu nge-pivot emaphakathi enyakazisa irola emuva maphakathi uma ibhande likhukhuleka liye ohlangothini olulodwa.Iphinde ihlanganise namarola angumhlahlandlela amabili ukuze asebenze njengemihlahlandlela yebhande.

I-Conveyor Belt

Ekumiseni i-conveyor yebhande, ibhande mhlawumbe liyinkimbinkimbi kakhulu.Ukuqina namandla kubalulekile njengoba ibhande lithatha isijeziso esikhulu lapho lilayisha futhi lihambisa impahla.

Isidingo esikhulayo sobude obude bokudlulisa siye sagqugquzela ucwaningo ezintweni ezintsha, nakuba lokhu kuhlala kuza ngezindleko.Amabhande aqinile anamathela ngokuqinile emithethweni ehambisana nemvelo avame ukuza nezindleko zokusetha eziphezulu, ngezinye izikhathi izindleko azikwazi ukuthethelelwa.Ngakolunye uhlangothi, uma kuthathwa indlela yokonga, ibhande ngokuvamile lihluleka, okuholela ezindlekweni eziphezulu zokusebenza.Izindleko zebhande ngokuvamile kufanele zibe ngaphansi kuka-50% wesamba sezindleko zomthumeli webhande.

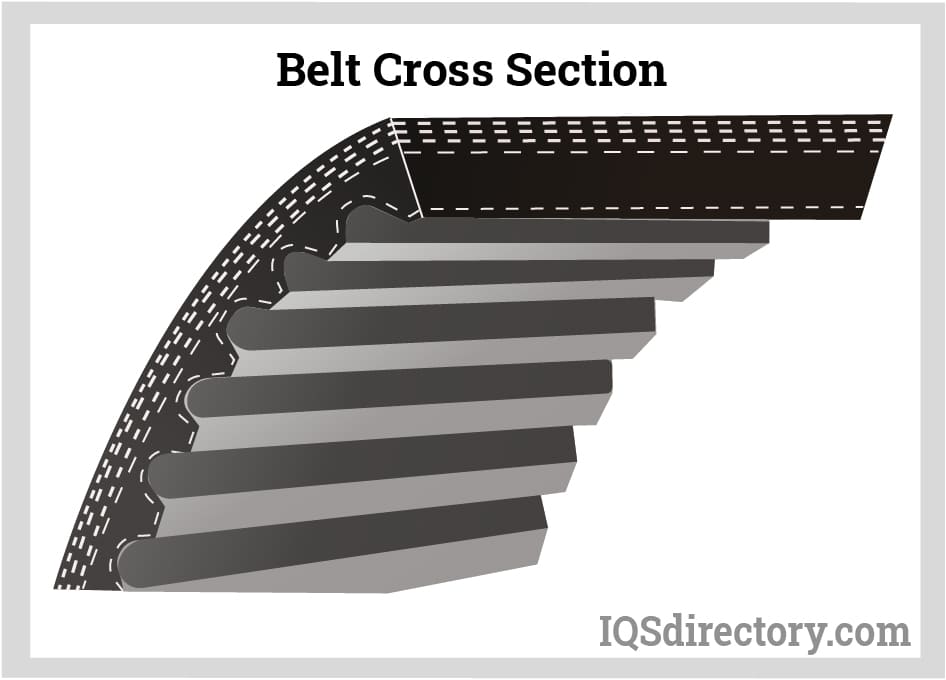

Ibhande lakhiwe izingxenye ezifana nalezi:

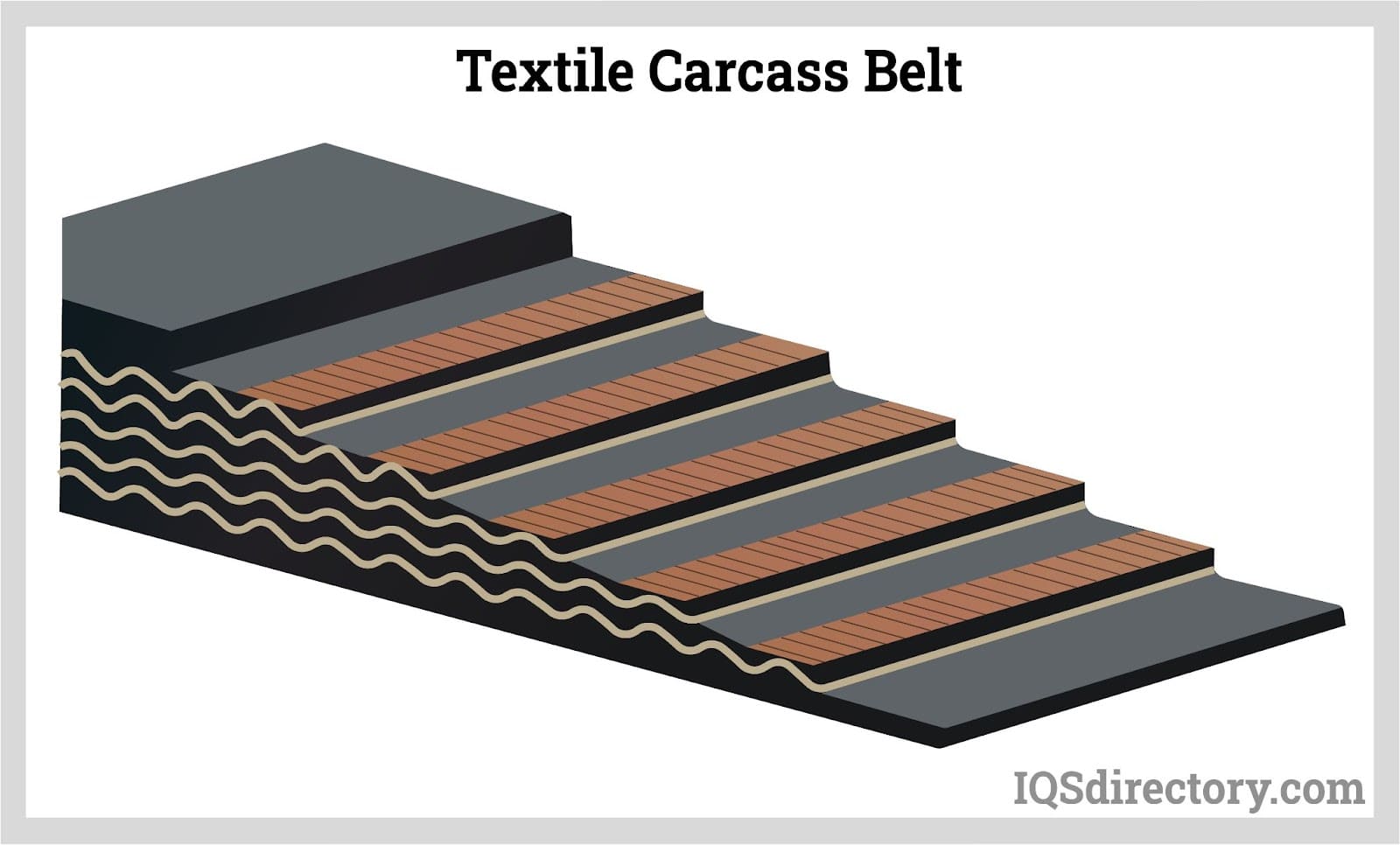

I-Conveyor Carcass

Njengoba lokhu kuwuhlaka lwamathambo ebhande, kufanele linikeze amandla aqinile adingekayo ukuhambisa ibhande kanye nokuqina kwe-lateral ukusekela umthwalo.Kufanele futhi ikwazi ukumunca umthelela wokulayisha.Ibhande liyiluphu ngakho-ke kufanele lihlanganiswe;lokhu kwaziwa ngokuthi yi-splicing.Ngenxa yokuthi ezinye zezindlela zokuhlanganisa zidinga ukusetshenziswa kwama-bolts nezinsimbi, isidumbu kufanele sikwazi ukunikeza isisekelo esanele nesiqinile salezi zibophelelo.

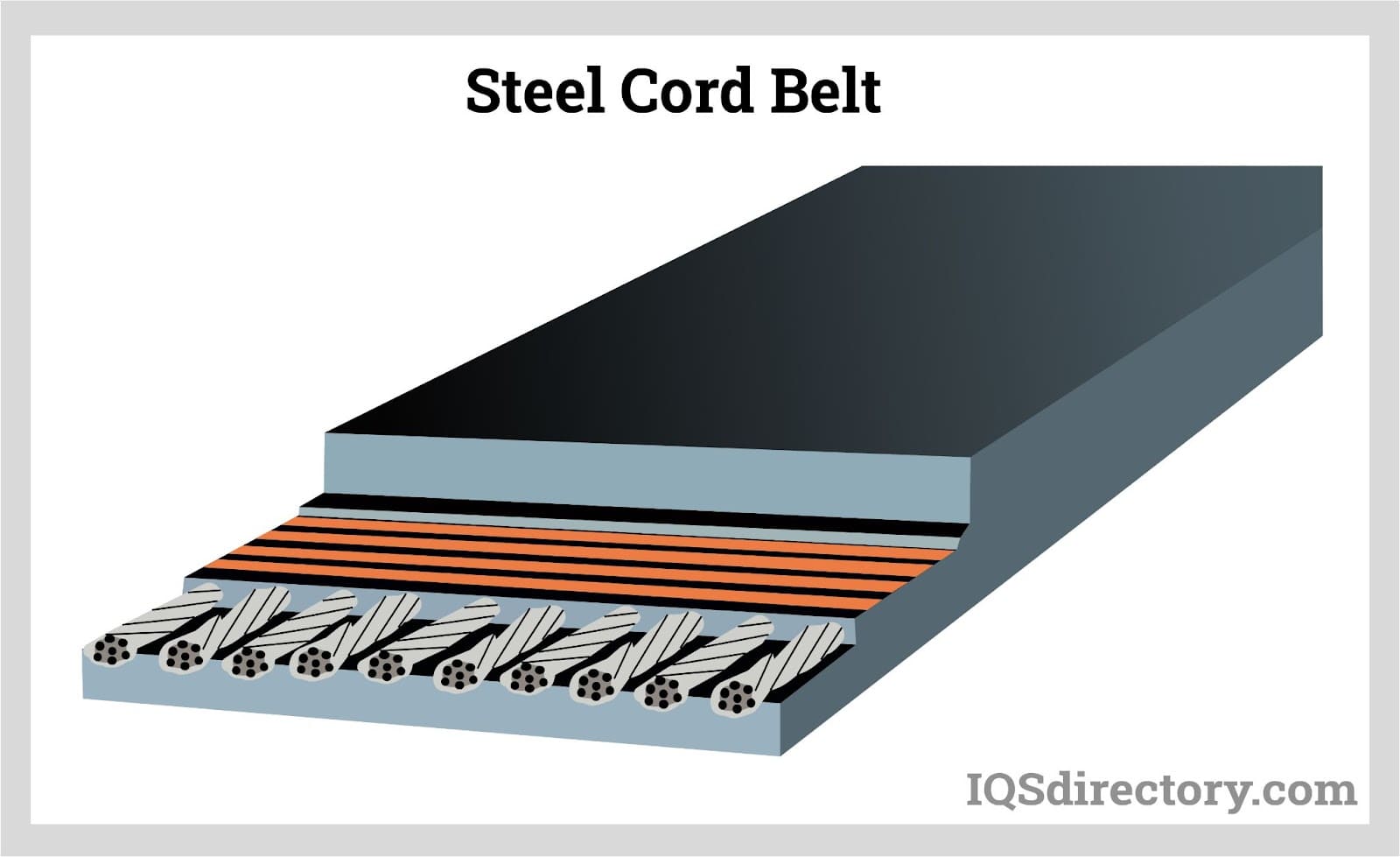

Isidumbu ngokuvamile senziwa ngentambo yensimbi noma i-textile ply.I-textile ply yenziwe ngemicu efana ne-aramid, i-polyamide, ne-polyester.Uma kusetshenziswa i-ply eyodwa kuphela, isidumbu se-PVC-coated textile sivamile.Izidumbu zingaba ngisho nezingqimba eziyisithupha zinqwabelane.I-carcass ingaphinda ihlanganise ukuvikela konqenqema okudingeka kakhulu kumabhande okuthutha ngobuningi.

Amakhava e-Conveyor (Phezulu naPhansi nezinhlangothi)

Lena impahla eguquguqukayo eyenziwe ngerabha noma i-PVC.Amakhava atholakala ngokuqondile ezici zesimo sezulu kanye nendawo yokusebenza.Ukucatshangelwa ngokucophelela kwamakhava kufanele kwenziwe kuye ngokusetshenziswa okuhlosiwe.Lokhu okulandelayo kuvame ukudinga ukunakwa, ukumelana nelangabi, ukumelana nezinga lokushisa eliphansi, ukumelana namafutha namafutha, i-anti-static, kanye nebanga lokudla.

Uhlangothi oluthwalayo lwe-conveyor kuye ngomthwalo, i-engeli yokuthambekela kwe-conveyor, kanye nokusetshenziswa okuvamile kwebhande konke kunezici ezikhethekile.Kungaba lukathayela, bushelelezi, noma kusulwe.

Ezinye izinhlelo zokusebenza ezifana namaconveyor alahliwe emishinini ye-CNC zizosebenzisa isidluliseli sebhande lensimbi njengoba lokhu ngeke kugqokwe njengoba kungenza ezinye izinto ezivamile.

Ezimbonini ezilungisa ukudla, amabhande e-PVC, e-PU, ne-PE nawo asetshenziselwa ukulondolozwa kokudla kanye nokunciphisa ukungcoliswa.

Amabhande epulasitiki masha, nakuba ngenxa yezinzuzo zawo ezinkulu, kancane kancane athola umfutho.Kulula ukuwahlanza, anebanga lokushisa elibanzi, futhi anezindawo ezinhle zokulwa nokubonakala kwe-viscosity.Ziyakwazi futhi ukumelana nama-asidi, amelana nezinto ezine-alkaline, namanzi anosawoti.

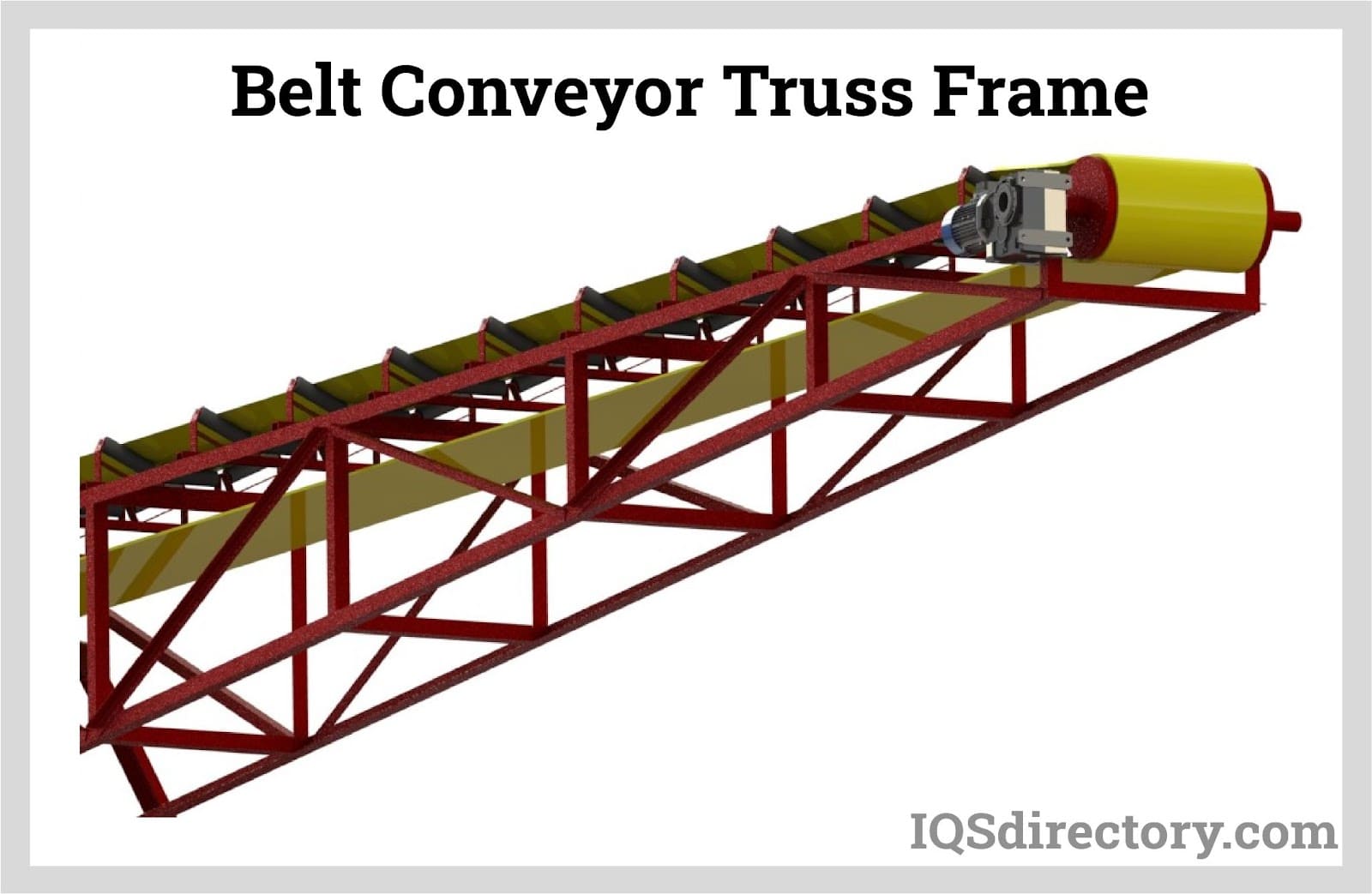

I-Conveyor Frame

Uhlaka, kuye ngokulayisha, ubude bokusebenza, nebanga elizofakwa kuzohluka.Bangafika ngokusetha okulula okungamelwa yi-cantilever.Angaba futhi ama-trusses esimweni semithwalo emikhulu.Ama-extrusions e-Aluminium nawo asetshenziselwa ukusebenza okulula nokulula.

Idizayini yefreyimu iyisici esibalulekile sedizayini ye-conveyor.Uhlaka oluklanywe kabi lungabangela:

- Ibhande liyaphela endleleni

- Ukwehluleka kwesakhiwo kubangela ukuthi:

- Izikhathi ezinde zokungasebenzi zihumusheka ekubambezelekeni kokukhiqiza

- Ukulimala kanye nabalimala

- Ukuchitheka Okubizayo

- Izindlela zokukhiqiza ezibizayo kanye nokufakwa.

Ohlakeni, ezinye izesekeli zingafakwa njengezindlela zokuhamba nokukhanya njengoba kuboniswe ngenhla.Izimo zokukhanyisa zizodinga amashede nonogada ukuvikela impahla.

Ama-chute okulayisha nokukhipha nawo angafakwa.Ulwazi lwazo zonke lezi zengezo ezingenzeka zibalulekile ukuze ugweme ukugcwala okungabaliwe.

Isahluko 2: Izinhlobo zeAma-Conveyors Amabhande

Lesi sahluko sizoxoxa ngezinhlobo zokuthutha amabhande.Lokhu kubandakanya:

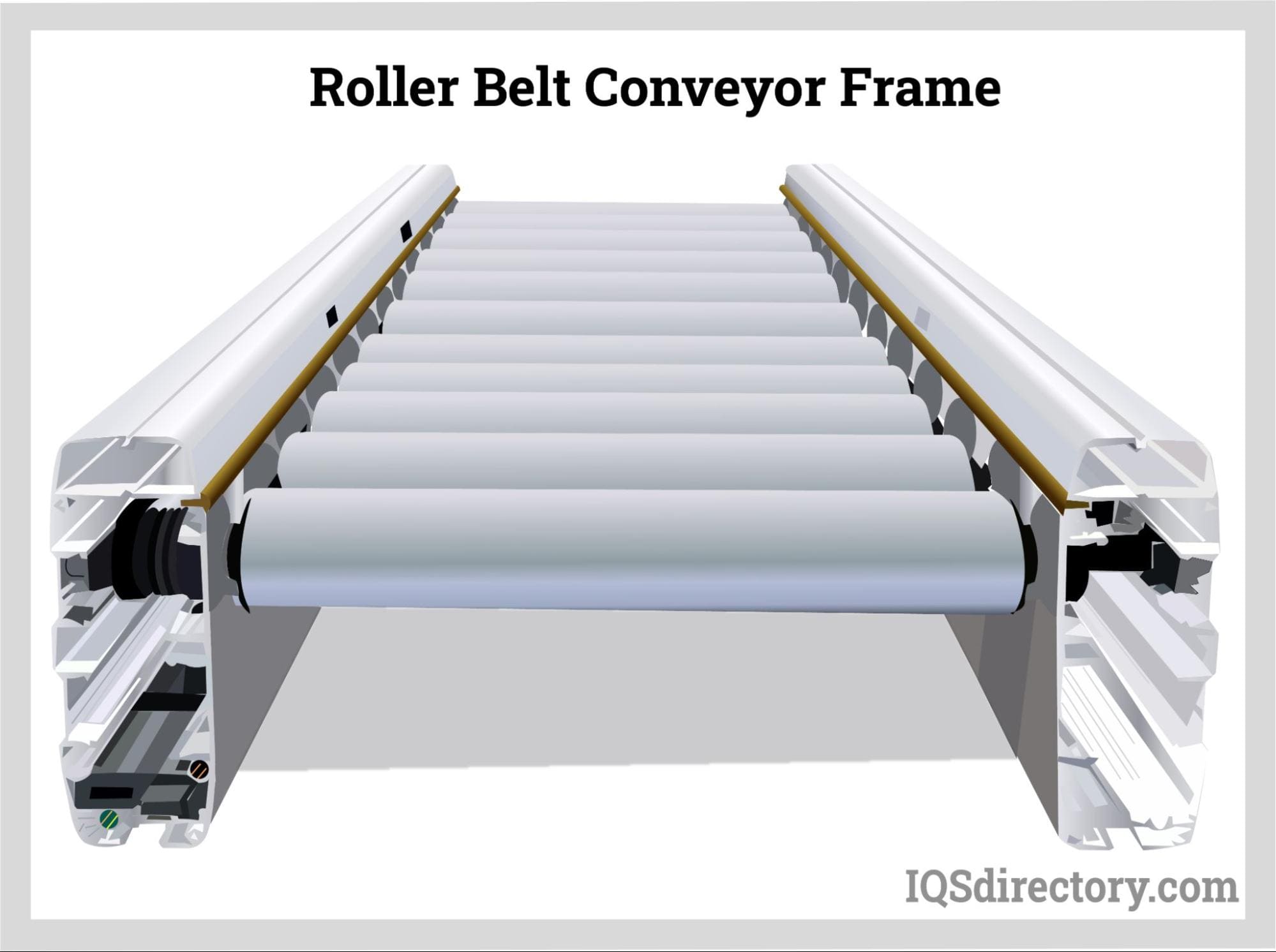

I-Roller Bed Belt Conveyor

Indawo engaphansi kwebhande kule nguqulo yebhande lokuhambisa lenziwe ngochungechunge lwama-roller.Ama-roller ahlanganiswe eduze ukuze kungabi nokuwohloka kwebhande.

Zifanele kokubili ukuthutha okude nokufushane.Kwezinye izimo, angaba mfushane kangangokuthi asebenzise kuphela ama-roller amabili kulo lonke uhlelo.

Uma usebenzisa amandla adonsela phansi ukulayisha, isihambisi sebhande le-roller singenye yezinketho ezingcono kakhulu ongakhetha kuzo.Uma umuntu esebenzisa ukulayisha mathupha, ukushaqeka kungalimaza ama-roller kalula ngoba ngokuvamile anama-bearing angaphakathi.Lawa ma-bearings kanye nendawo evame ukubushelelezi yama-roller kunciphisa kakhulu ukungqubuzana okwenza kube lula ukudlulisa.

Amabhande ombhede asetshenziswa kakhulu lapho kukhona ukuhlelwa, ukuhlanganisa, ukuthutha nokuhlolwa ngesandla.Izibonelo zifaka:

- Ukuphatha imithwalo yesikhumulo sezindiza

- Ukuhlunga izinto ze-courier kuhlanganise namahhovisi eposi

I-Flat Belt Conveyor

I-conveyor yebhande eliyisicaba ingenye yezinhlobo ezivame kakhulu zokuthutha.Ngokuvamile isetshenziselwa ukuthutha izinto ngaphakathi kwendawo.Ukuthutha kwangaphakathi kudinga uchungechunge lwamarola/amapuli anamandla ukudonsa ibhande.

Amabhande asetshenziselwa ukuthutha ibhande eliyisicaba ayahluka kusuka ezindwangu, nama-polymers kuya kumarabha emvelo.Ngenxa yalokhu, ishintshashintsha ngokuya ngezinto okufanele zithuthwe.Futhi kulula kakhulu ukuvumelanisa ne-pulley yomsila ngokuvamile efakwe ukuze ikwazi ukulungiswa ukuze iqondanise ibhande.Ngokuvamile kuba ibhande elihamba ngesivinini esiphansi.

Izicelo ze-flat belt conveyor zihlanganisa:

- Imigqa yokuhlanganisa ehamba kancane

- Izinhlelo zokusebenza zokugeza

- Umhlangano wezimboni ezinothuli olula

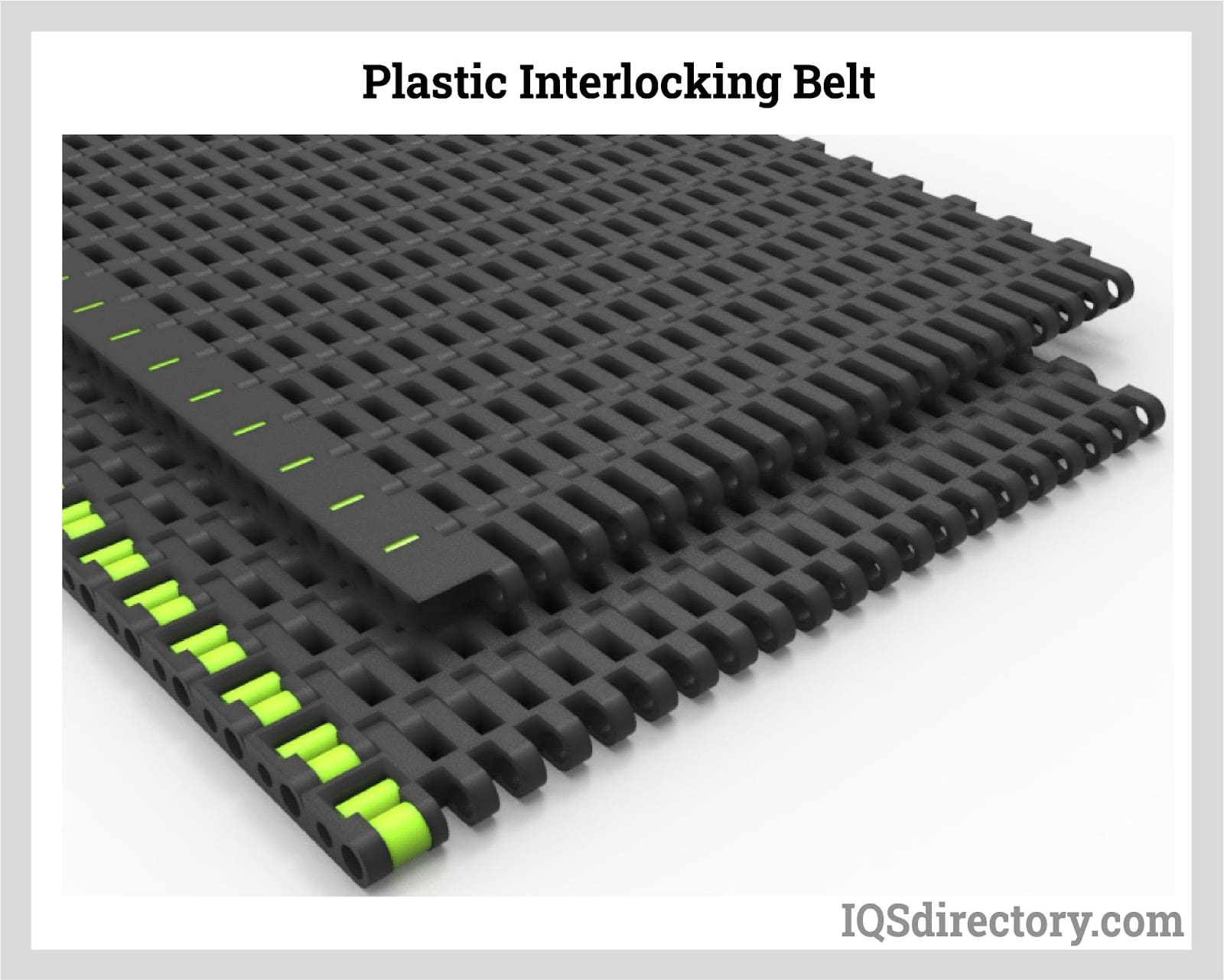

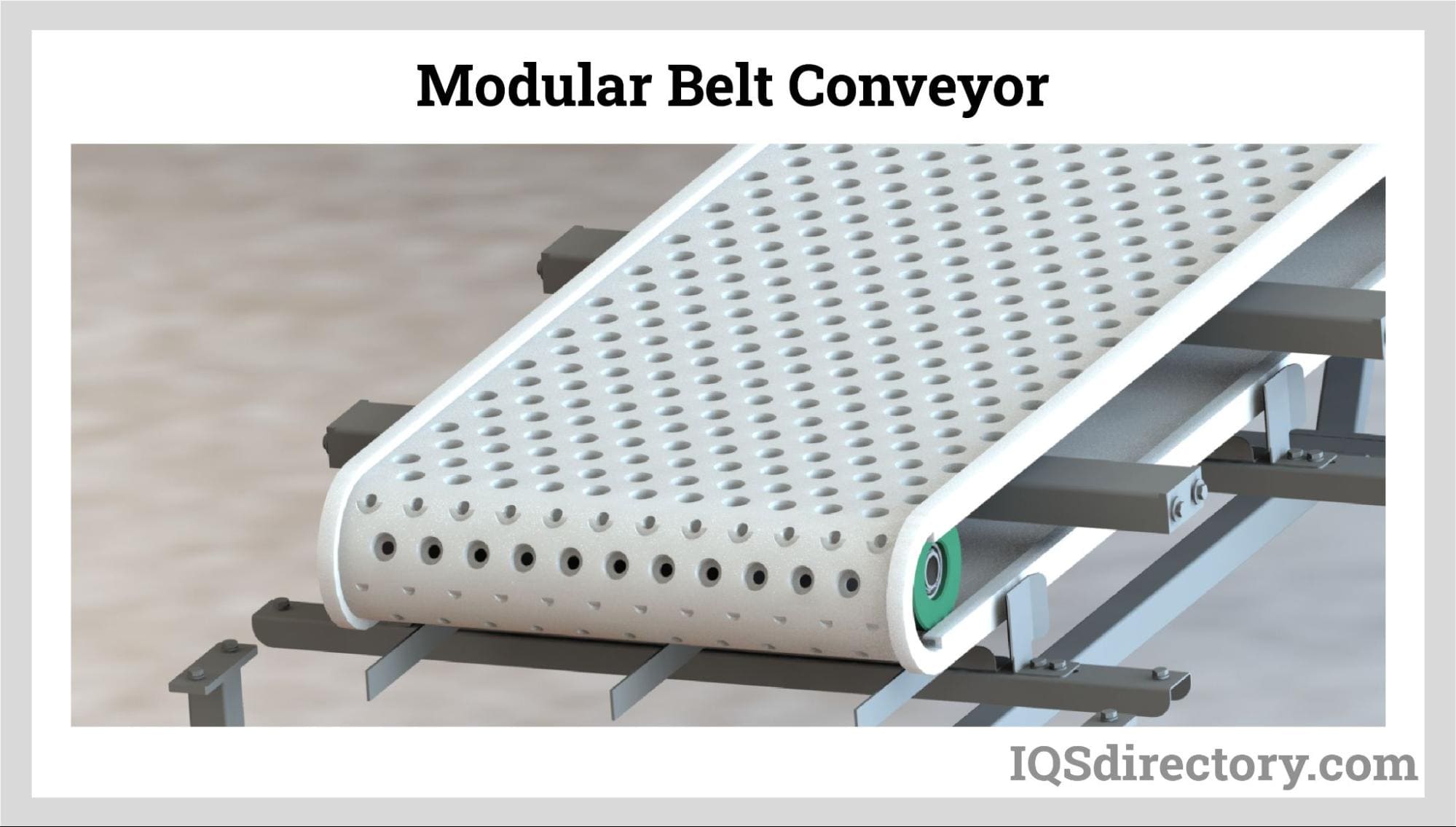

I-Modular Belt Conveyor

Ngokuphambene namabhande ayisicaba asebenzisa iluphu “engenamthungo” yebhande eliguquguqukayo, ama-Modular Belt conveyors asebenzisa uchungechunge lwezicucu eziqinile ezixhumene ngokuvamile ezenziwe ngepulasitiki noma insimbi.Zisebenza kakhulu njengoba kwenza iketango ebhayisikilini.

Lokhu kubanika inzuzo enkulu ngaphezu kozakwabo bamabhande aguquguqukayo.Kuwenza abe mahlehle ngoba angasebenza ebangeni elibanzi lamazinga okushisa namazinga we-PH.

Lapho ingxenye yebhande yonakala, umuntu angashintsha kalula leso sigaba eyedwa esikhundleni samabhande aguquguqukayo lapho kuzofanele kushintshwe lonke ibhande.Amabhande e-modular angahamba, esebenzisa injini eyodwa kuphela, azungeze amakhona, imigqa eqondile, ama-inclines, kanye nokwehla.Njengoba nje abanye abathumeli bempahla bengenza okufanayo, kuza ngezindleko zobunzima kanye nezimali.Kuzinhlelo zokusebenza ezingase zidinge ububanzi "obungajwayelekile" obukhulu kunobude, noma uhlobo lwe-conveyor, ama-modular belt conveyor azofeza lokho kulula kakhulu.

Njengoba zingezona ezensimbi, kulula ukuzihlanza, futhi zinezimbotshana zegesi noketshezi, amabhande okuhambisa amabhande angasetshenziswa ku:

- Ukuphatha Ukudla

- Ukuphatha uketshezi

- Ukutholwa kwensimbi

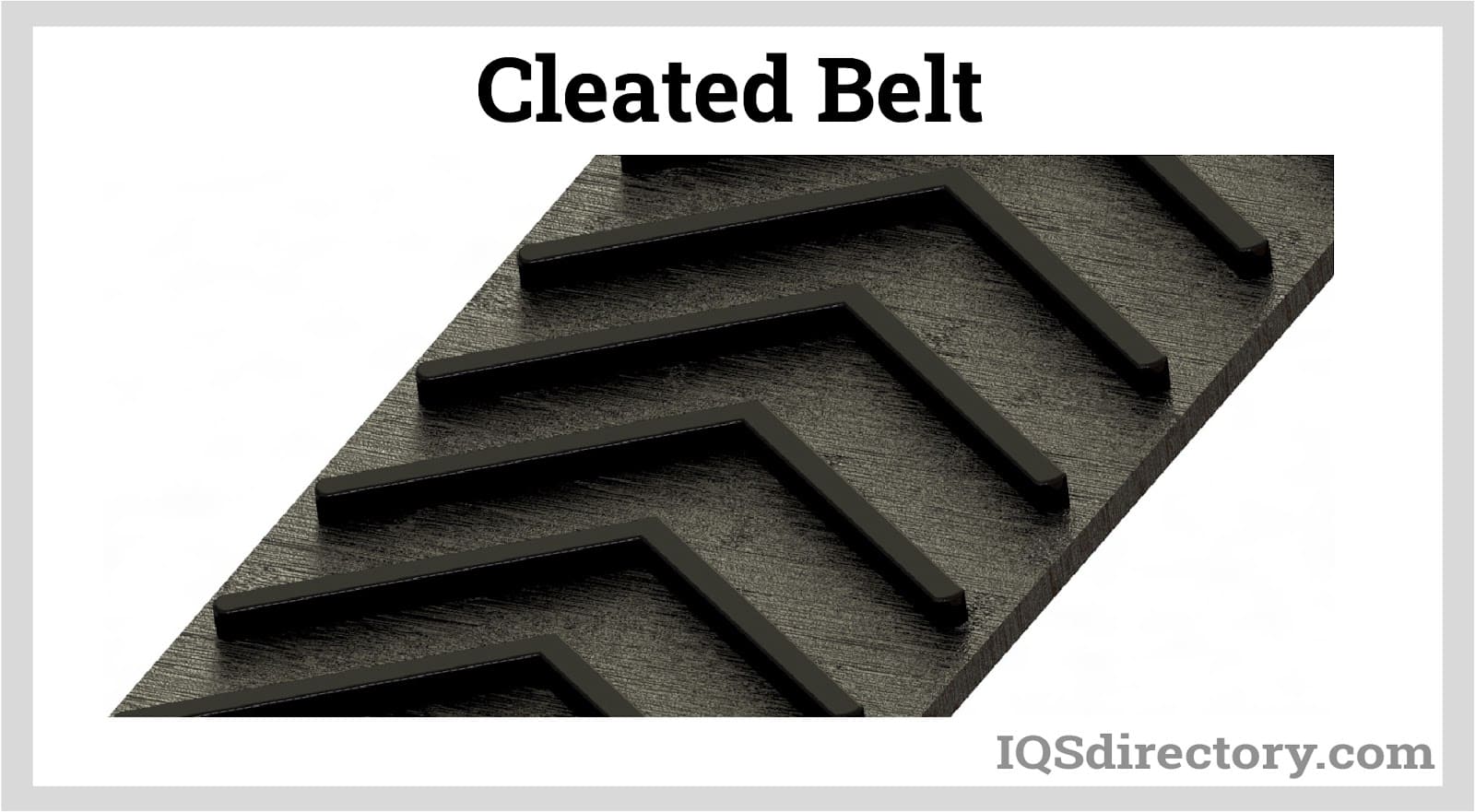

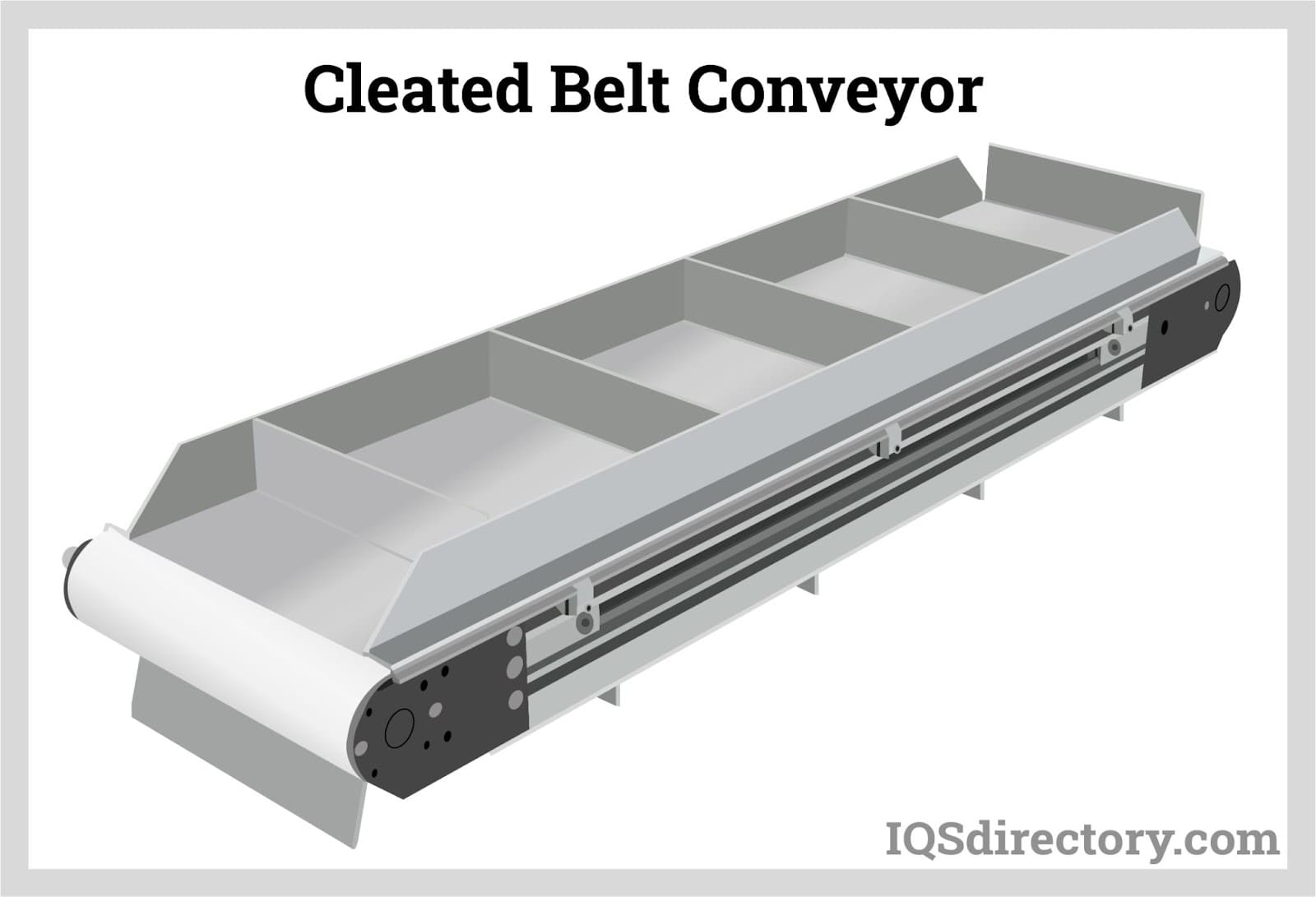

I-Cleated Belt Conveyor

Izihambisi zamabhande asuliwe zizohlala zinesithiyo noma zicacile ekwakhiweni kwazo.Ama-cleats asebenza ukuhlukanisa izingxenye ezilinganayo ebhandeni.Lawa masegimenti agcina izinhlayiya nezinto ezingahle zihlehle noma ziwe kusihambisi ngesikhathi sokuthamba nokuncipha.

Ama-cleat afika ngezindlela ezihlukahlukene nobukhulu obuhlanganisa:

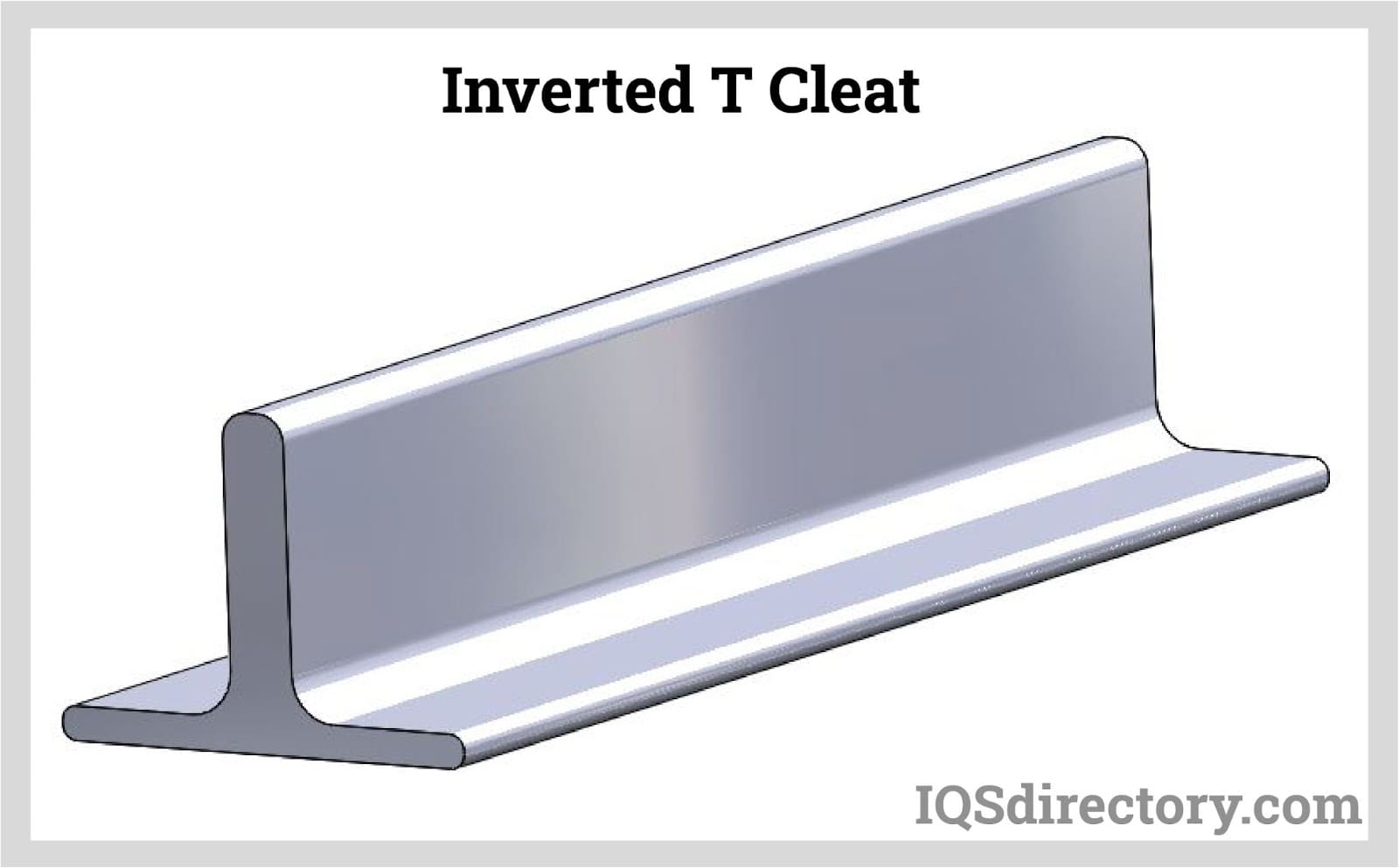

I-Capital Eguquliwe T

Le cleat izoma kuma-degree angu-90 ukuya ebhandeni ukunikeza ukusekela nokuguquguquka kwezinto ezibucayi.Ifaneleka kakhulu ukwenza imisebenzi elula nokuphatha izingxenye ezincane, izimpahla ezipakishiwe, nemikhiqizo yokudla.

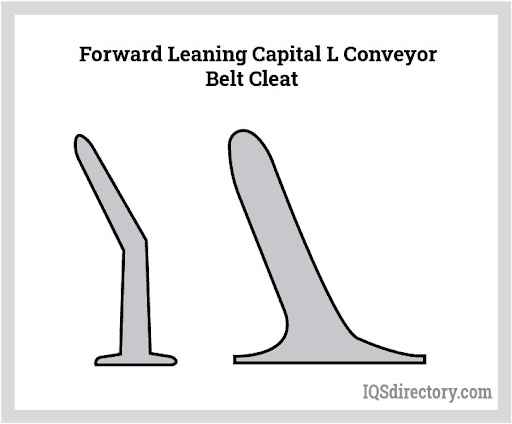

I-Forward-Leaning Capital L

Ngenxa yokuma kwayo, ingamelana kalula namandla anamandla.Ingasetshenziselwa ukukha ama-granules futhi uwabambe ngokumelene namandla adonsela phansi.Ingasetshenziselwa ukubamba ama-granules alula ukuya kwesisindo esimaphakathi.

Ama-V Cleats ahlanekezelwe

Lawa ma-cleans angaphansi kuka-5cm ubude ukuze abe nomthelela ofanayo nalowo onawo umkhombe.Angasetshenziselwa ukuthutha inqwaba yempahla esindayo noma enkulu ngenxa yokwaluka kwawo okufushane, okungamelana nemithelela ephezulu.

Izikhonkwane nezikhonkwane

Lawa ma-cleats asetshenziselwa ukusiza ukugeleza koketshezi ngemuva kokugeza izinto ezifana nemifino nezithelo.Izigxobo nezikhonkwane kuyindlela engabizi kakhulu yokudlulisa izinto nezinto ezingadingi ukusekelwa kulo lonke ubude bebhande njengamabhokisi amakhulu noma izinduku.Angaphinda asetshenziselwe ukuhambisa ngokukhetha imikhiqizo eyeqa usayizi ofunwayo futhi abambe imikhiqizo eyodwa endaweni.

Okunye ukusetshenziswa kweCleated Belt Conveyors kufaka phakathi:

- Izitebhisi ezizihambelayo ziwukushintshwa kwezithuthi zebhande elisuliwe ngomqondo wokuthi zithwala izinto ezixegayo zikhuphukele endaweni engumqansa.

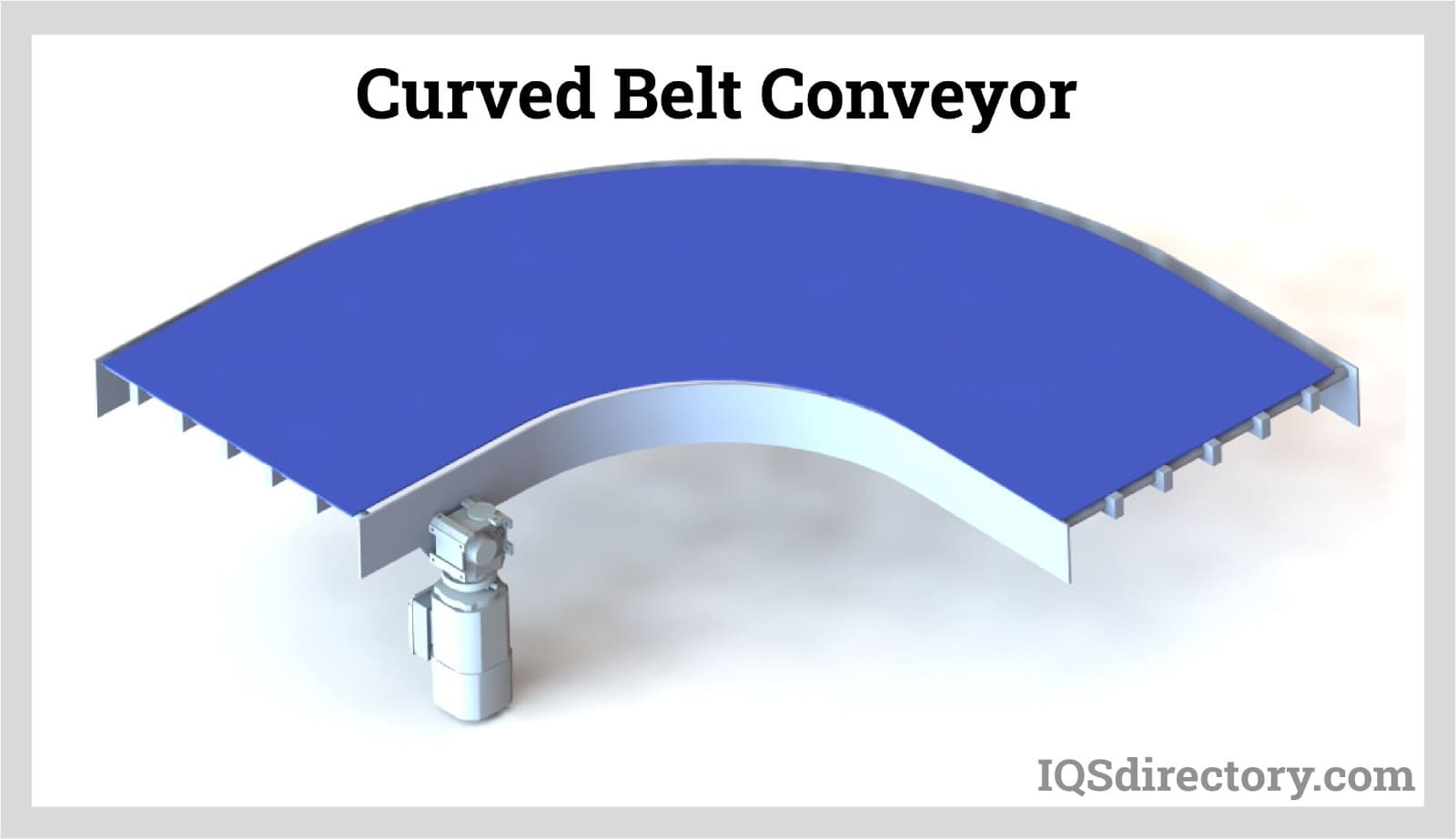

I-curved Belt Conveyor

Lesi sihambisi sisebenzisa uhlaka olwakhiwe futhi oluvele lugobile ukuze luthwale izinto emakhoneni aqinile.Isetshenziswa lapho isikhala silinganiselwe futhi amaconveyor asongayo angasindisa isikhala.Amajika angahamba aze afike ku-180 degrees.

Kusetshenziswa amapulasitiki ajwayelekile anamasegimenti ahlanganayo kodwa kuphela uma isihambisi sinomzila oqondile ngaphambi kokuba sijike.Amabhande athambile athambile azosetshenziswa uma ibhande ngokuyinhloko ligobile.

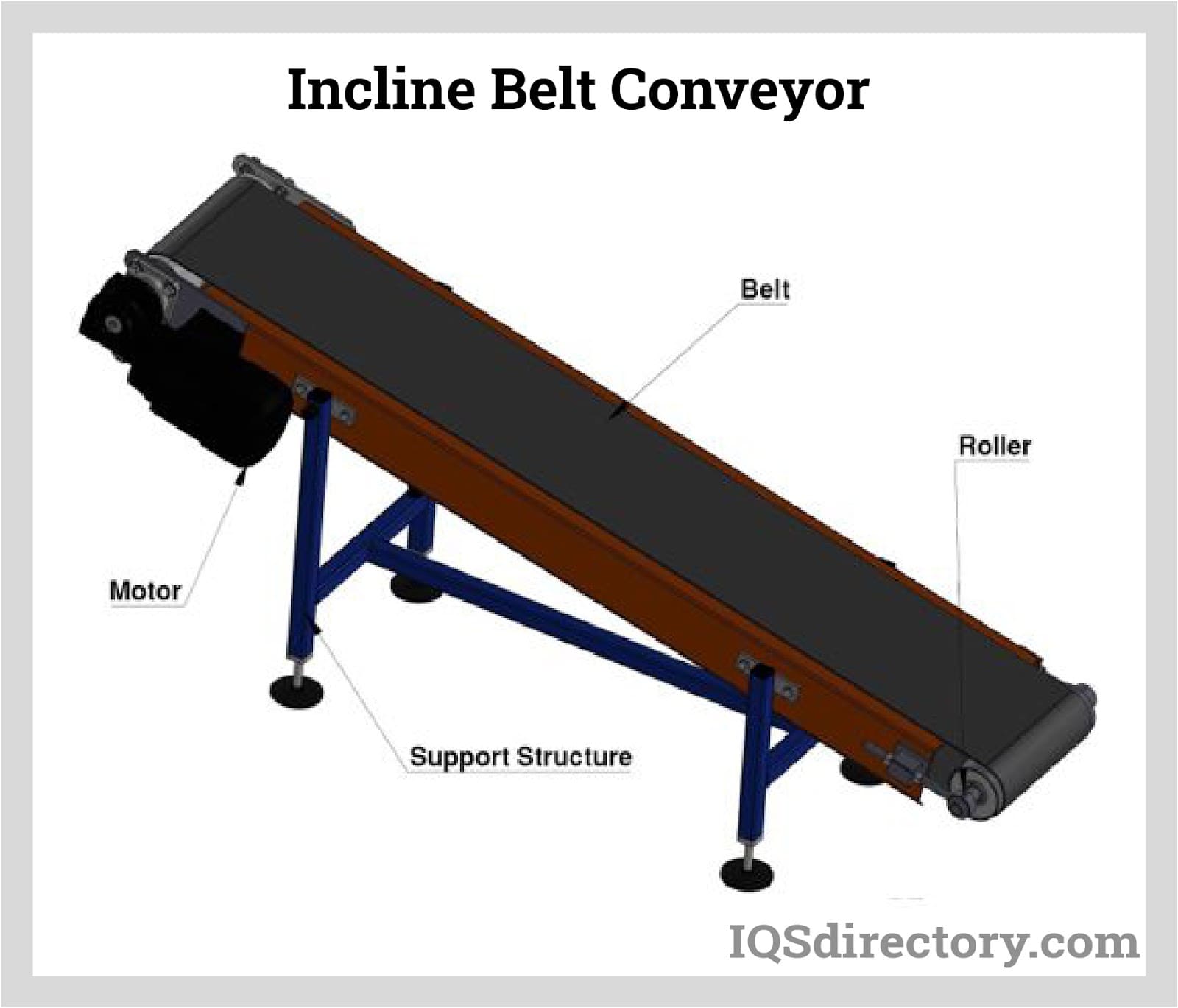

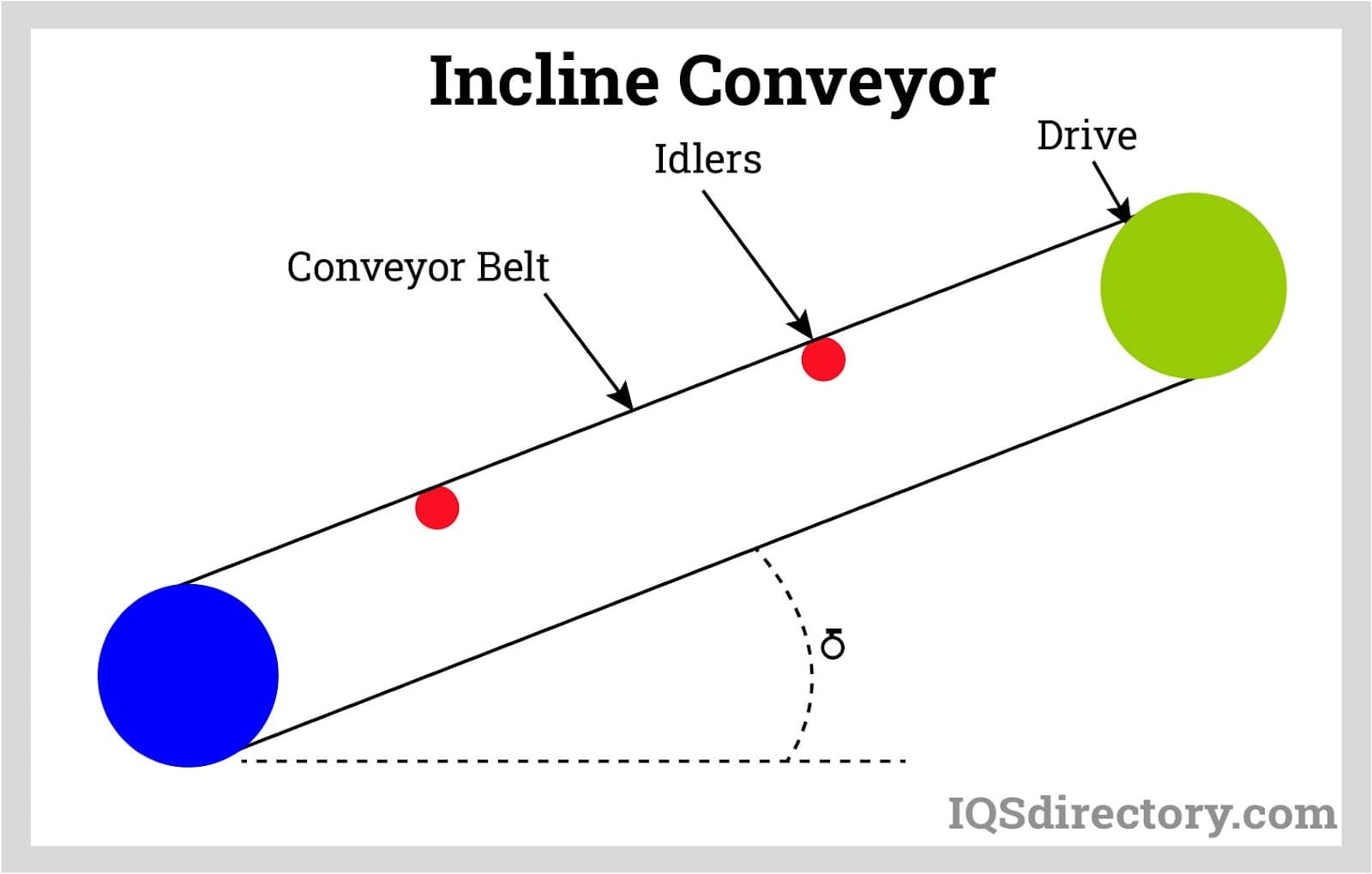

I-Cline/Decline Belt Conveyor

Amaconveyor e-incline adinga amandla aqinile we-tension, i-torque ephakeme, kanye nokudonsa endaweni yebhande ukuze kuvinjelwe izinto ekuweni kwebhande le-conveyor.Ngakho-ke, bazofaka injini yegiya, idrayivu ephakathi nendawo, kanye nokuthatha.Ibhande kufanele futhi libe nendawo emangelengele ukuze likwazi ukudonsa.

Njengama-cleat conveyor, lezi nazo zithwala izinto zikhuphukele phezulu zingavumeli izinto ziwe.Angasetshenziswa futhi ukuthuthukisa ukugeleza kwamandla adonsela phansi oketshezi.

I-Sanitary Washdown Conveyor

Ezimbonini zemithi nokudla, ukuvala inzalo nokuwashwa kanzima ngokuvamile kudingeka kwenzeke, ngokuhambisana neziqondiso zezempilo nezokuphepha.Imishini yokuwasha kanye ne-sanitary conveyor yakhelwe ukuphatha izinqubo zenhlanzeko zalolo hlobo.Amabhande asetshenziswa lapha ngokuvamile amabhande ayisicaba acishe abe mncane.

Amabhande okugeza amabhande ahlanzekile asetshenziswa ezintweni eziphuma emazingeni okushisa aphezulu njengeziqandisi neziko.Kwesinye isikhathi kufanele basebenze emafutheni ashisayo noma kucwebezeliswe.Ngenxa yokuthi zikwazi ukuphatha kahle izindawo ezinamafutha, ngezinye izikhathi zisetshenziselwa ukukhulula izigubhu zikawoyela namakesi emikhunjini.

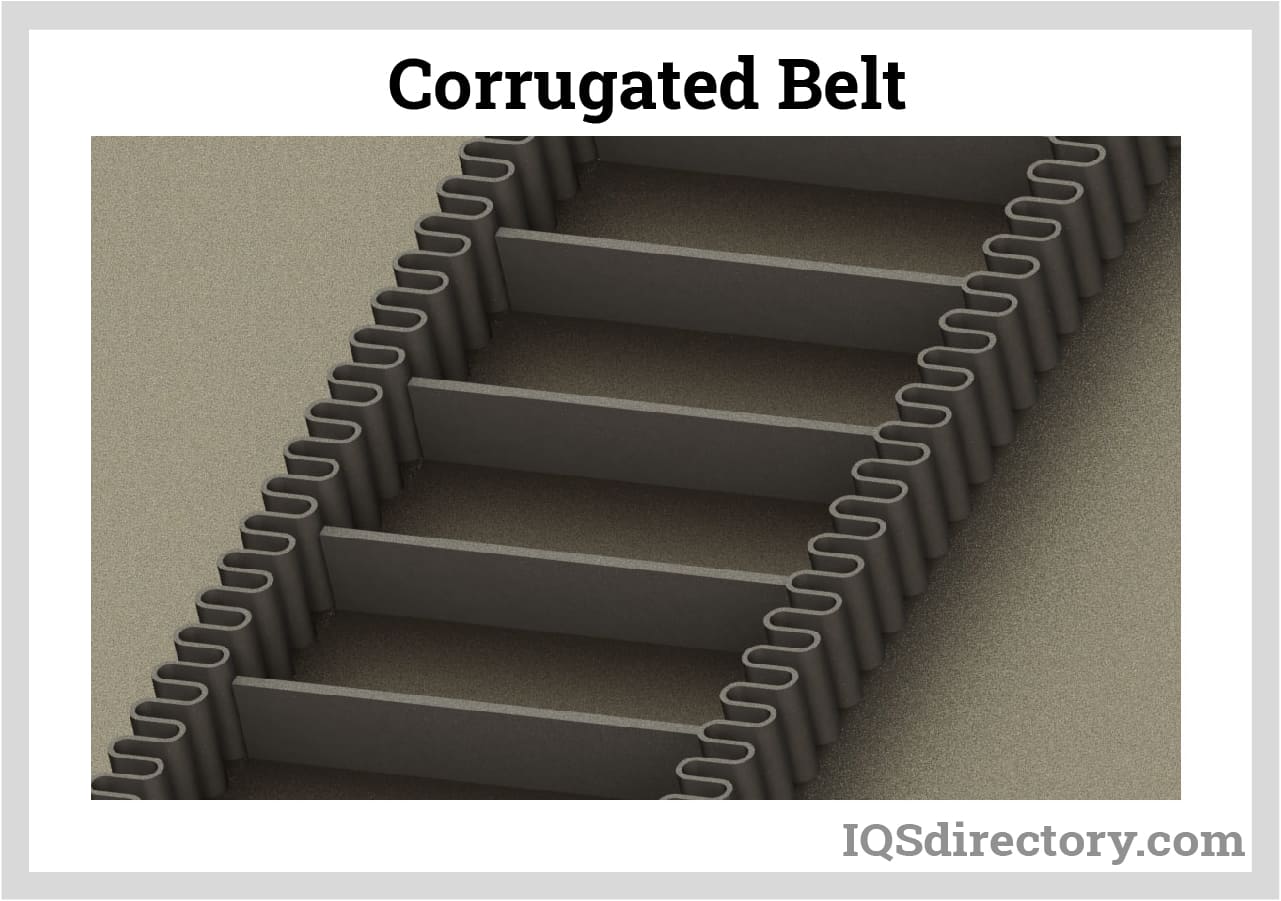

Ama-Conveyors Akhonjiwe

I-conveyor yebhande lokudonsa akulona uhlobo oluhlukile lwebhande ngoba i-troughing ingafakwa kunoma yiluphi uhlobo lwe-conveyor.

Isebenzisa ibhande elenza umumo ogoqiwe ngenxa yamarola angenzi lutho ngaphansi kwawo.

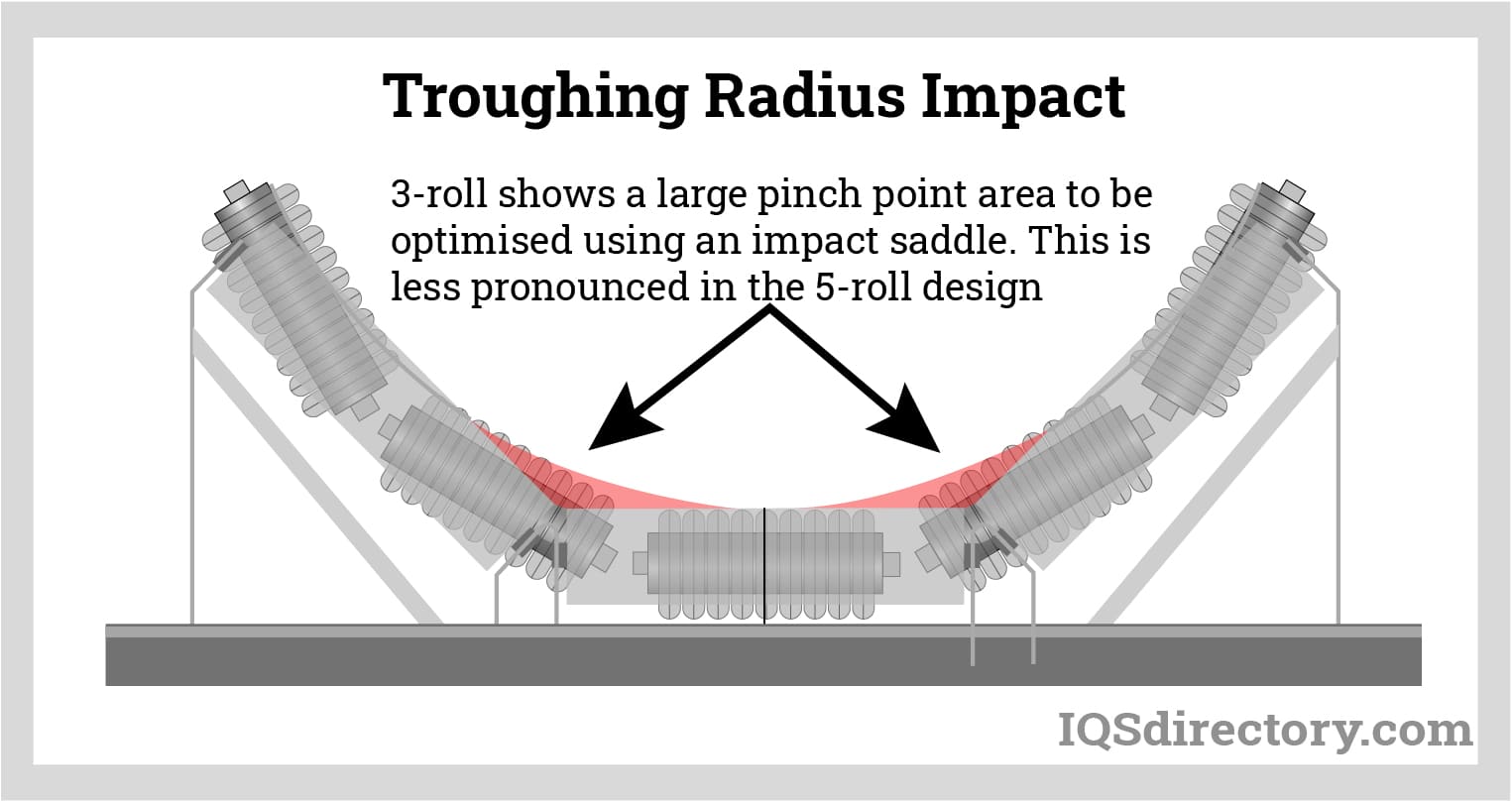

Amarola angenzi lutho adonsayo anerola elimaphakathi eline-eksisi evundlile yokuzungezisa, futhi amarola amabili angaphandle (ama-wing roller) ane-eksisi ephakanyiswe nge-engeli eya endaweni evundlile.I-engeli ivamise ukuba ngu-25 degrees.Ukubhoboza kwenzeka kuphela kumarola amavila aphezulu futhi awakwenzi abe phansi ngempela.

Ama-engeli aphezulu okudonsa amanzi azodala umonakalo unomphela ebhandeni.Uma ibhande linyathelwa ngama-engeli aphakeme, lizogcina isimo senkomishi yalo futhi kuzoba nzima ukulihlanza, kube nzima ukulandelela kanye nokuphula isidumbu sebhande.Kungase futhi kunciphise inani lokuxhumana okungaphezulu namarola angasebenzi, okugcina kunciphisa ukusebenza kahle kwesistimu yokuthutha ibhande.

Amabhande e-trough ngokuvamile asebenza endizeni eyodwa, evundlile noma egobile, kodwa ethambekela afinyelela kuma-degree angama-25 kuphela.Ibhande kufanele libe ne-radius enkulu ngokwanele ukuze likwazi ukuthinta wonke ama-roller akumuntu ongenzi lutho.I-engeli ecijile yokudonsa isho ukuthi ibhande ngeke lithinte i-roller engenzi lutho emaphakathi, ngaleyo ndlela kulimaze ubuqotho besakhiwo sebhande kanye nokusebenza kahle kwesistimu yokuthutha yonkana.

Isahluko sesi-3: Ukuklanywa Nokukhethwa Kwezithuthi Zebhande

Lapho uklama ibhande lokuthutha, imingcele emikhulu okufanele icatshangelwe yilena:

- Ukukhetha motor kanye gearbox

- Ijubane lebhande

- Ukungezwani nokuthatha

- Izinto okufanele zidluliselwe

- Ibanga okufanele uhanjiswe ngalo

- Indawo yokusebenza isb. izinga lokushisa, umswakama, njll.

Ukukhethwa Kwezimoto Nebhokisi Lomshini

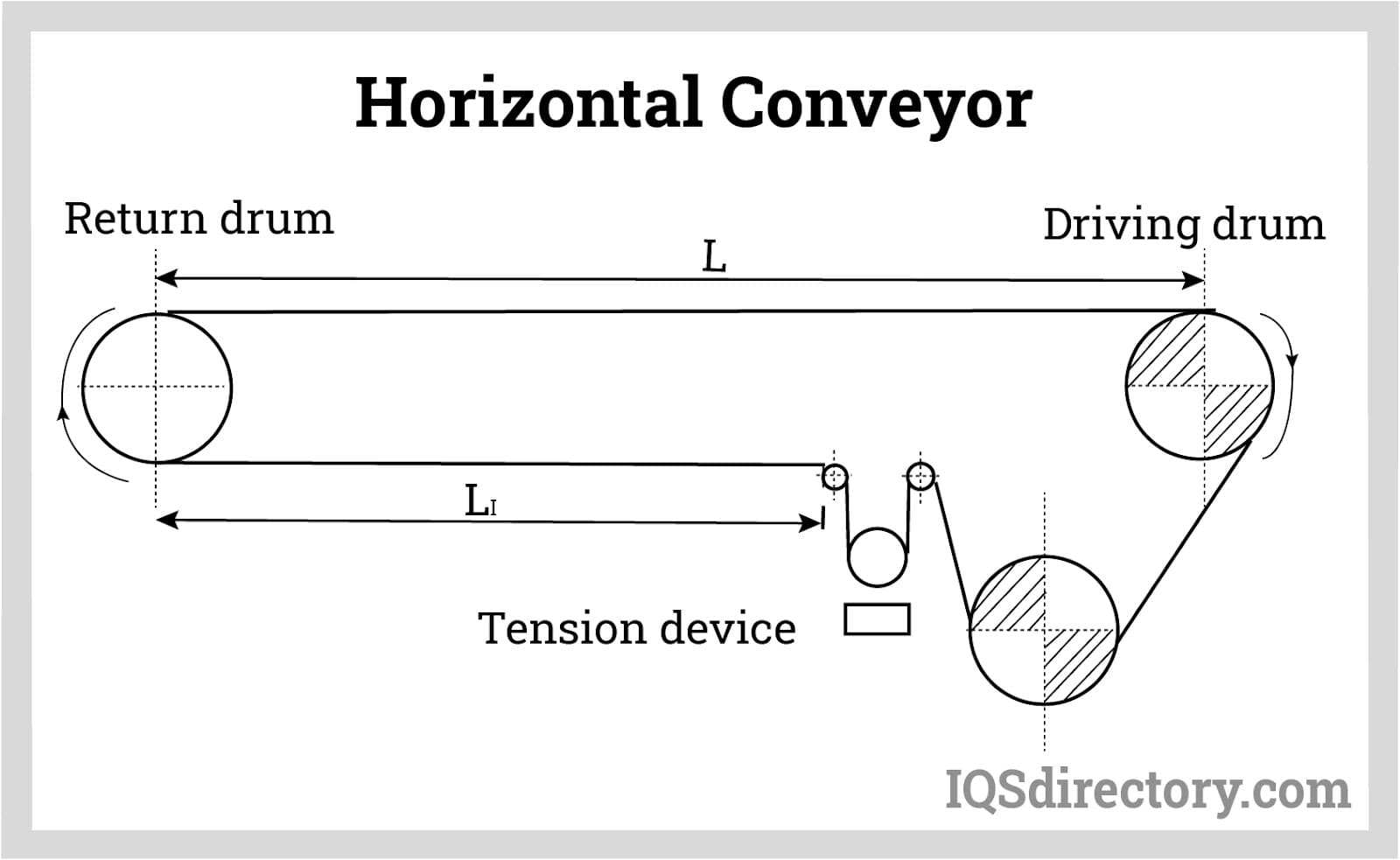

Ukuze usize ekukhetheni injini, umuntu kufanele aqale azi ukuthi amandla okudonsa asebenzayo adingekayo ku-conveyor ayini.

Ukuze uthole isidluliseli esilula esivundlile, amandla okudonsa asebenzayo anikezwa ifomula engezansi:

Fu=µR*g*(m+mb+mR)

Kuphi

- Fu = Amandla okudonsa asebenzayo

- µR = I-Friction Coefficient lapho igijima phezu kwerola

- g = Ukusheshisa ngenxa yamandla adonsela phansi

- m = Inqwaba yezimpahla ezidluliswa kubo bonke ubude besithuthi

- mb = IMisa Lebhande

- mR = Inqwaba yawo wonke ama-roller ajikelezayo khipha isisindo se-drive roller

Ngohlelo ekuthambekeni, amandla okudonsa asebenzayo anikezwa kanjena:

Fu=µR*g*(m+mb+mR)+gmsina

Kuphi

- Fu = Amandla Okudonsa Aphumelelayo

- µR = I-Friction Coefficient lapho igijima phezu kwerola

- g = ukusheshisa ngenxa yamandla adonsela phansi

- m = inqwaba yezimpahla ezidluliswa kubo bonke ubude besithuthi

- mb = IMisa Lebhande

- mR = Inqwaba yawo wonke ama-roller ajikelezayo khipha isisindo se-drive roller

- α = I-engeli yokuthambekela

Uma sekunqunyiwe amandla okudonsa, kuba lula ukuthi uqhamuke ne-torque bese kuthi injini isetshenziswe bese kuthi u-gearbox ulandele ngemuva.

Isivinini se-Conveyor

Isivinini somthumeli sizoba yindilinga yesiyingi se-pulley yokushayela ephindaphindwe ngokushintshashintsha ngesikhathi seyunithi.

Vc=DF

- Vc = Isivinini sebhande lokuthutha ku-ms-1

- D = Ububanzi be-pulley yokushayela ngamamitha.

- F = Ukuguqulwa kwe-pulley yokushayela ngomzuzwana

Ishumision kanye Nokuthathwa Kwebhande

Ukuthatha kuyisici esibalulekile ekugcineni nasekuzuzeni ibhande eliqinile.Lokhu kuzoba nomthelela omkhulu ohlelweni kanye nokuzinza kwayo kwemishini.

Ibhande eliqine ngendlela efanele lizogqokwa ngokulinganayo futhi lizoqukatha okubalulekile ngokulinganayo ku-trough futhi ligijime phakathi nendawo lapho lidlula phezu kwamavila.

Wonke ama-conveyor azohlala ezwa ukunwebeka okuthile ngobude nobubanzi bawo.Ngokuvamile, kuyamukeleka ukuthi ibhande elisha lizokwelula ngamaphesenti angu-2 engeziwe obude balo bangempela.Njengoba le ngxenye izokwengeza ubude bebhande, lonke ibhande lizoba ne-slack.Lokhu kuxega kuyodingeka kuthathwe ukuze kugcinwe ukushuba okuphezulu.

Uma i-conveyor iba yinde, i-stretch izoba nkulu.Ngokusebenzisa i-stretch engu-2%, i-conveyor engamamitha angu-2 ubude ingakwazi ukwelula u-40mm, kodwa i-conveyor engamamitha angu-200 ubude izoxega ngamamitha angu-4.

Ukuthatha futhi kunenzuzo uma ibhande kufanele lilungiswe.Esimeni esinjalo ukuyithatha kuyayekwa futhi abasebenzi bayolungisa kalula.

Izinhlobo Zokuthatha I-Belt Conveyor

Kuningi ukucushwa kokuthatha, ngakunye kunobuhle nokubi.Ukucushwa okujwayelekile kokuthathwa kwesithuthi sebhande ukuthatha amandla adonsela phansi, ukuthatha isikulufu, nokuthatha okuvundlile.

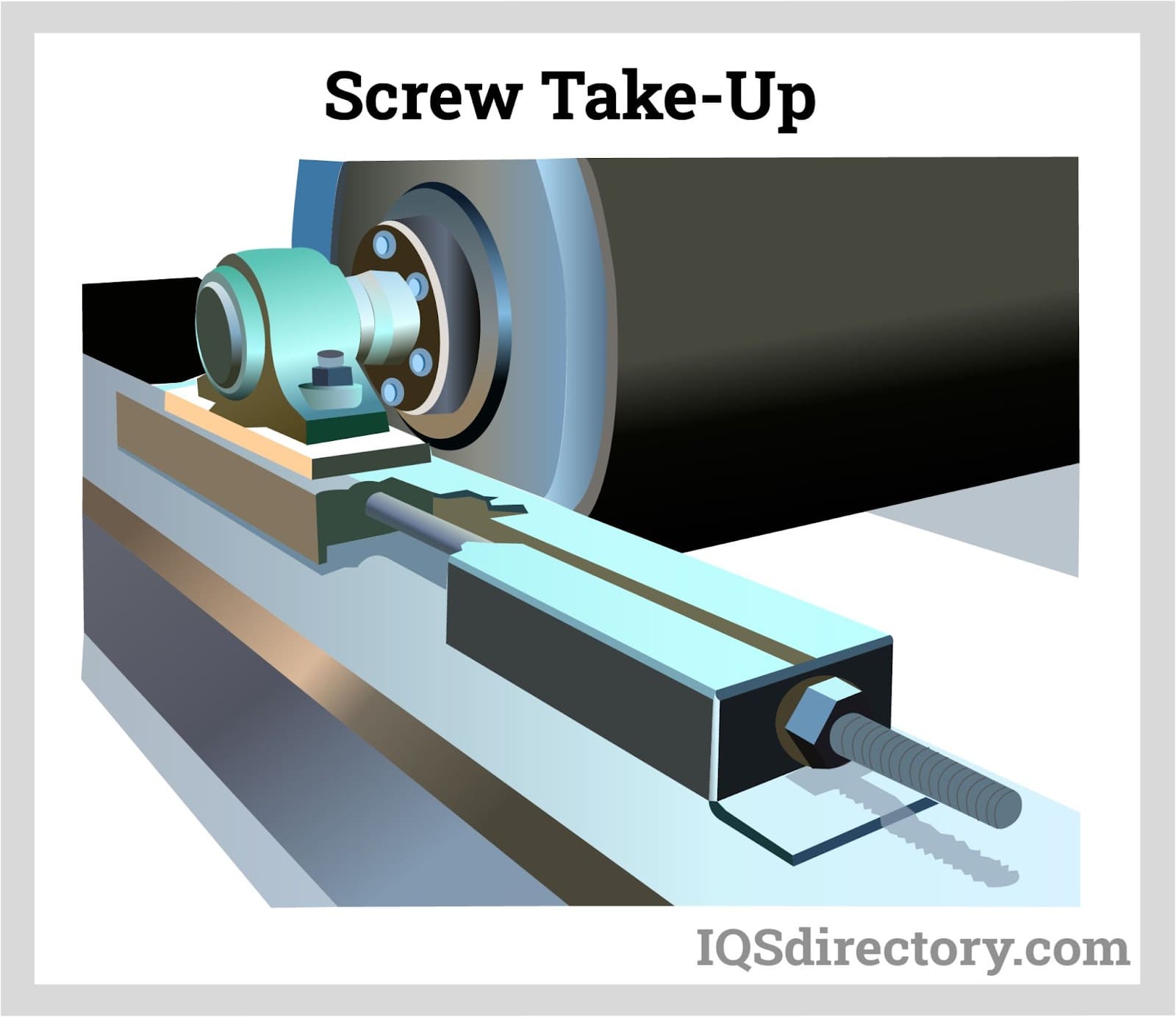

I-Screw Take-Up

Ukulungiselelwa kokuthatha isikulufu kusebenzisa amandla omshini ukuze kubambe konke ukuxega ebhandeni.Ifinyelela ngokulungisa induku enentambo exhunywe kwelinye lama-roller, ikakhulukazi i-tail roller.Le nduku enentambo izoba ohlangothini ngalunye lwerola ngakho ingasebenza njengenqubo yokuqondanisa.Njengoba lena kuyindlela yokwenza ngezandla, ukuthatha isikulufu kuvame ukubizwa ngokuthi ukuthatha ngezandla.

Esinye isitayela sibizwa ngokuthi i-top angle take-up.Yize idumile futhi, idinga uzimele omkhulu nosindayo womsila ukuze ifakwe kungobo yomlando.Onogada nabo kumele babe bakhulu.

Ukuthatha isikulufu kuyindlela eshibhile nesebenzayo yokulawula ukungezwani kwebhande kumaconveyor amafushane futhi kuyindlela elula nejwayelekile yokuthatha kwabaningi.

I-Gravity Take-Up

Ukuthatha izikulufu ngokuvamile akufanelekile ukufaka ubude bokwelula okwenzeka kumaconveyor amade angaphezu kwamamitha ayi-100.Kulokhu kusetha, ukuthatha amandla adonsela phansi kuzoba yindlela engcono kakhulu yokuqinisa amabhande.

Ukuhlanganiswa kokuthatha amandla adonsela phansi kusebenzisa amarola amathathu lapho amabili azoba amarola okugoba futhi enye ibe i-gravity noma i-sliding roller elawula ukungezwani kwebhande njalo.I-counterweight ezogxunyekwa ku-rola yokuthatha amandla adonsela phansi idonsela phansi ebhandeni ukuze ivikele ukungezwani ngokusebenzisa amandla adonsela phansi.Amarola okugoba aqondisa ibhande elixegayo eduze nerola yokuthatha amandla adonsela phansi.

Ukuhlanganiswa okugcwele kokuthatha kuhlanganiswe phansi kohlaka lokuthutha futhi kwenza ukungezwani okuqhubekayo ebhandeni.Le ndlela yokuhlelwa kokuziqinisa ivumela ukuthatha ukuthi kulungiswe kalula kuma-spikes angazelelwe ekucindezelekeni noma ekulayisheni.

Ngakho-ke, indlela yokuthatha amandla adonsela phansi ihlale igcina ukungezwani okufanele kwebhande futhi igwema ukulimala kwebhande ngenxa yomthwalo ongazelelwe noma ama-tension spikes.Njengoba amandla adonsela phansi ezicindezela ngokwawo, adinga ukulungiswa okuncane, ngokungafani nendlela yokuthatha isikulufu.

Ukugcinwa kwazo ngokuvamile kuyadingeka lapho ibhande selifinyelele ekupheleni kwesikhathi salo sokuphila.Kulapho-ke selunwebe ngendlela yokuthi umhlangano usufike ekugcineni kwebanga lokuhamba elibekiwe.Uma lokhu kwenzeka, ibhande lokuthutha lizodinga ukushintshwa noma lisikwe futhi libe sengozini.Isistimu yokuthatha amandla adonsela phansi yaziwa nangokuthi ukuthatha okuzenzakalelayo ngoba iyazilungisa ngokuzenzakalelayo.

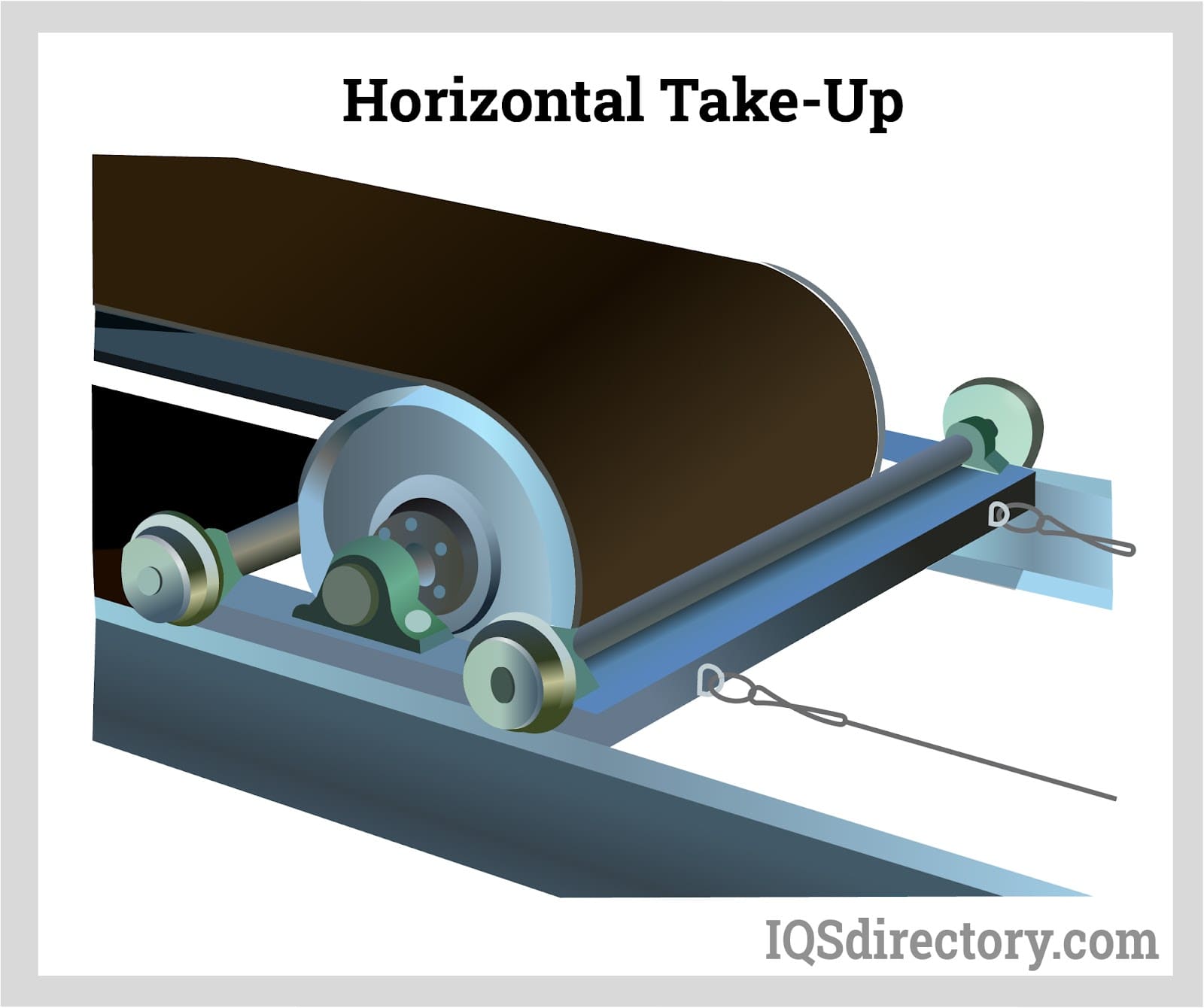

Ukuthatha Okuvundlile

Ukuthatha okuvundlile kungena esikhundleni sokuthatha amandla adonsela phansi kodwa kuphela lapho isikhala sinomkhawulo.Lokhu kuthathwa kufana nokuthatha amandla adonsela phansi, kodwa esikhundleni sokuthi umhlangano ube ngaphansi kwebhande, umiswe mpo ngemuva kwerola yomsila.Lokhu kukwenza kuzuzise ngokukhethekile lapho isihambisi sibekwe ebangeni elingenaso isikhala esengeziwe ngaphansi kwesithumeli.

Ngenxa yokuthi ukuthatha okuvundlile ngeke kuwele ngaphansi kwesithumeli, ukuhlelwa kwezintambo nama-pulleys kusetshenziselwa ukuqinisa ibhande ngebhokisi lesisindo.Izintambo ezixhunywe kwi-pulley yomsila zigibela ikalishi elivumela ukuthi ingene futhi iphume endaweni.

Isahluko 4: Izicelo kanye Nemihlomulo Yezithuthi Amabhande

Lesi sahluko sizoxoxa ngokusetshenziswa kanye nezinzuzo zabathumeli bebhande.Izophinde ixoxe ngezinkinga ezivamile zokuthutha ibhande, izimbangela zazo, kanye nemiphumela yemvelo kumabhande amabhande.

Izicelo zama-Belt Conveyors

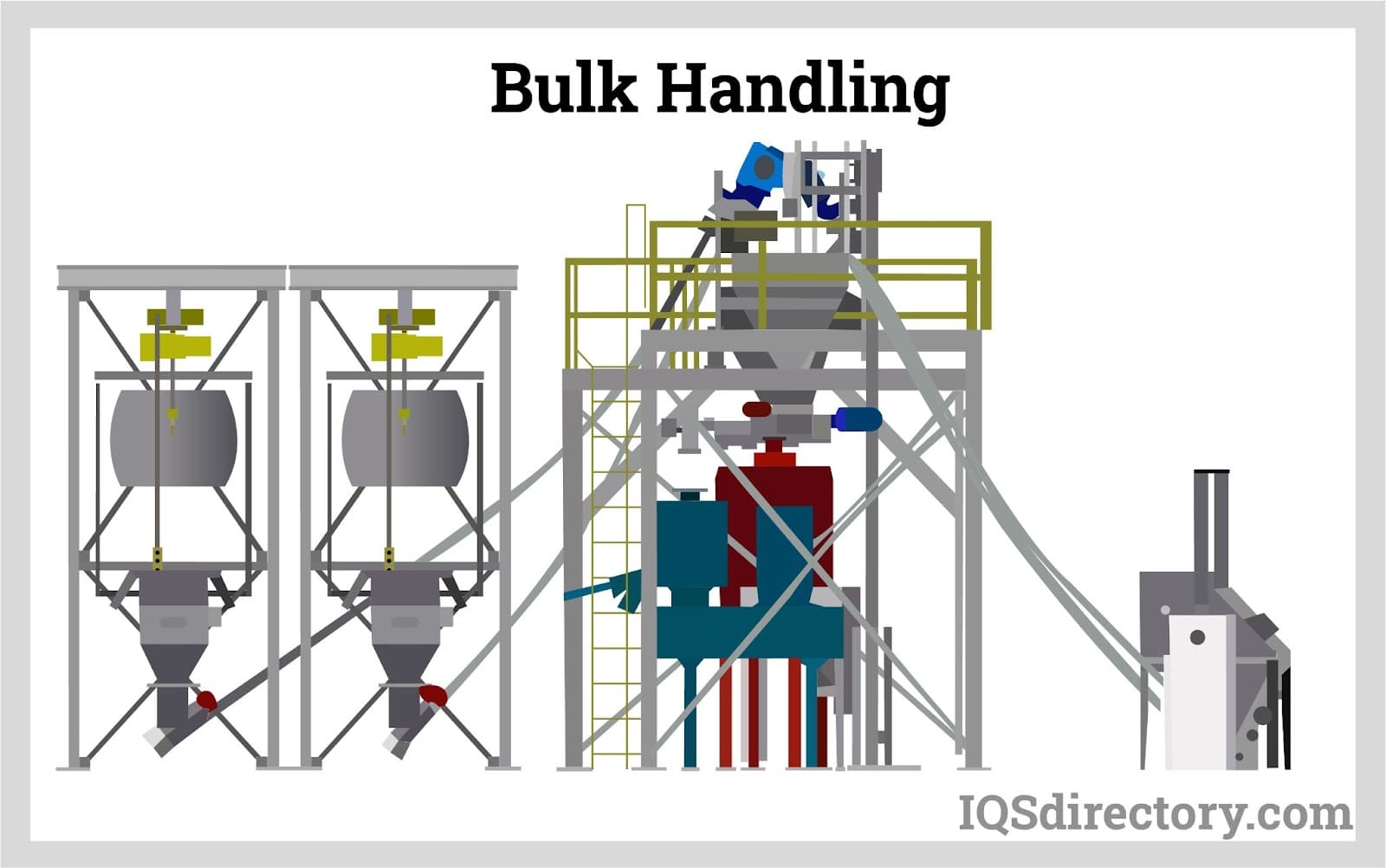

Amabhande okuthutha anezinhlobonhlobo zezinhlelo zokusebenza kuzo zonke izimboni.Lokhu kubandakanya:

Imboni Yezimayini

- Ukuphatha ngobuningi

- Ukucubungula izitshalo

- Ukuthatha ama-ores ukusuka ku-shaft kuya ezingeni eliphansi

Imboni Yezimoto

- Abadlulisi bomugqa wokuhlanganisa

- Izihambisi ezilahliwe zemishini ye-CNC

Imboni yezokuthutha kanye ne-Courier

- Abathutha imithwalo ezikhumulweni zezindiza

- Izithuthi zokupakisha ekuthumeni kwe-courier

Imboni yokudayisa

- Ukupakishwa kwe-warehouse

- I-Till point conveyors

Ezinye izinhlelo zokusebenza ze-conveyor yilezi:

- Izimboni zokuphatha ukudla zokuhlelwa nokupakishwa

- Ukukhiqiza amandla okuhambisa amalahle kuma-boilers

- Civil kanye nezokwakha njengezitebhisi ezizihambelayo

Izinzuzo Amabhande Conveyors

Izinzuzo zamabhande okuthutha zihlanganisa:

- Kuyindlela eshibhile yokuhambisa izinto emabangeni amade

- Akwehlisi isithunzi somkhiqizo odluliswayo

- Ukulayisha kungenziwa kunoma iyiphi indawo eduze kwebhande.

- Ngama-trippers, amabhande angakwazi ukulayisha noma kunini kulayini.

- Abakhiphi umsindo omningi njengezinye izindlela zabo.

- Imikhiqizo ingakalwa nganoma yisiphi isikhathi ku-conveyor

- Zingaba nezikhathi ezinde zokusebenza futhi zingasebenza ngisho nezinyanga ngaphandle kokuma

- Ingaklanywa ukuthi ihambe futhi imile.

- Yiba nobungozi obuncane ekulimaleni komuntu

- Izindleko Zokulungisa Eziphansi

Izinkinga Zokuthwala Ibhande Elivamile

Kunezinkinga ezimbalwa amasistimu okuthutha amabhande angathambekela kuzo futhi azodinga ukuncishiswa.Lokhu kubandakanya:

Inkinga 1: I-Conveyor Igijima Iya Ehlangothini Olulodwa endaweni ethize Ohlelweni

Izinkinga zalokhu zingabandakanya:

- Ukwakhiwa kwezinto phezu kwamavila noma okuthile okwenza amavila anamathele

- Amavila awasagijimi isikwele kumzila wesihambisi.

- Uzimele we-Conveyor utshekile, ugoqekile, noma awusekho ileveli.

- Ibhande alizange lihlukaniswe ngokulinganayo.

- Ibhande alilayishwanga ngokulinganayo, mhlawumbe lilayishwe ngaphandle maphakathi.

Inkinga 2: Ibhande Le-Conveyor liyashelela

Izinkinga zalokhu zingabandakanya:

- Ukudonsa kubi phakathi kwebhande ne-pulley

- Amavila abambekile noma awazungezi ngokukhululeka

- I-pulley legging egugile (igobolondo elizungeze i-pulley elisiza ukwandisa ukungqubuzana).

Inkinga 3: Ukwelulwa Kwebhande

Izinkinga zalokhu zingabandakanya:

- I-tensioner yebhande iqine kakhulu

- Ukukhetha impahla yebhande akwenziwanga kahle, mhlawumbe “ngaphansi kwebhande”

- I-Conveyor counterweight inzima kakhulu

- Igebe phakathi kwama-idle rolls lide kakhulu

Inkinga 4: Ibhande Ligqoka Kakhulu Emaphethelweni

Izinkinga zalokhu zingabandakanya:

- Ibhande lilayishwe ngaphandle maphakathi

- Umthelela ophezulu wezinto ezibonakalayo ebhandeni

- Ibhande eligijima ngokumelene nesakhiwo sokuthutha

- Ukuchitheka Kwempahla

- Impahla ibanjwe phakathi kwebhande ne-pulley

Imiphumela Yezemvelo Kumabhande Okuthutha

Amanzi, imikhiqizo kaphethiloli, amakhemikhali, ukushisa, ukukhanya kwelanga, nokubanda konke kuthonya ukusebenza nokuphila kwesithuthi sebhande.

Izimbangela nemiphumela ingahlukaniswa kanje:

Umswakama Effects

- Ibhande liyabola futhi liyaqhekeka

- Ibhande ukunamathela okuxekethile

- Ibangela ukushelela

- Izidumbu zensimbi zingagqwala

Imithelela Yokukhanya Kwelanga Nokushisa

- Irabha izokoma futhi ibe buthakathaka

- Irabha izoqhekeka

- Irabha ingase ibe nokuxega okwengeziwe futhi ngaleyo ndlela inciphise ukungezwani kwebhande

Imiphumela Ebandayo

- Ibhande liyaqina futhi kuba nzima ukuqondisa nokuqeqesha

- Ezinhlelweni ze-incline, isithwathwa singakheka futhi sibangele ukushelela

- Iqhwa lingakheka kuma-chutes futhi liwavale

Imiphumela Yamafutha

- Injoloba izovuvukala

- Irabha izolahlekelwa amandla aqinile

- Irabha izolahlekelwa amandla aqinile

- Ibhande lizogqokwa ngokushesha

- Irabha izolahlekelwa ukunamathela

Isiphetho

I-belt conveyor iyisistimu eklanyelwe ukuthutha noma ukuhambisa izinto ezibonakalayo njengempahla, izimpahla, kanye nabantu ukusuka endaweni eyodwa ukuya kwenye.Ngokungafani nezinye izindlela zokudlulisa ezisebenzisa amaketango, ama-spirals, ama-hydraulics, njll., amabhande okuthutha azohambisa izinto kusetshenziswa ibhande.Kubalulekile ukuqaphela ukucatshangelwa kokuklama kanye nokusetshenziswa kwama-conveyor amabhande ahlukahlukene kuye ngokusetshenziswa okuhlosiwe.

Ukuqaliswa kwevidiyo

Izinsiza zomkhakha we-Conveyor zonjiniyela

Idizayini Yesakhiwo kanye Nemibandela Ye-Roller Conveyor

Ii-roller conveyorilungele ukudlulisa zonke izinhlobo zamabhokisi, izikhwama, amaphalethi, njll.Izinto eziningi, izinto ezincane, noma izinto ezingajwayelekile zidinga ukuthuthwa ngamaphalethi noma ngamabhokisi okwenza imali.

I-Pipe belt conveyor kanye nezimo zohlelo lokusebenza

Iisihambisi sepayipiinezinhlobonhlobo zezinhlelo zokusebenza.Ingakwaziizinto zokuthutha zibheke phezulu, ngokuvundlile, futhi ngokutshekile kuzo zonke izinhlangothi.Futhi ukuphakama kokuphakamisa kuphakeme, ubude bokudlulisa bude, ukusetshenziswa kwamandla kuphansi, futhi isikhala sincane.

Izinhlobo zokuthutha ibhande le-GCS kanye nesimiso sohlelo lokusebenza

Isakhiwo esivamile sokuthutha ibhande ngezindlela ezihlukahlukene, umshini webhande lokukhuphuka, umshini webhande elitshekile, umshini webhande elifakiwe, umshini webhande eliyisicaba, umshini webhande eliphendukayo nezinye izinhlobo.

UFUNA UKUSEBENZA NATHI?

Isikhathi sokuthumela: May-26-2022