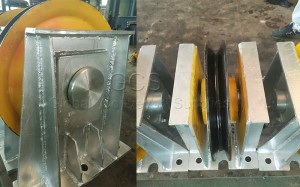

I-Cast Iron Wheel Frame yama-Haulage Pulleys

I-V-Belt Casting Pulleys

Singabanye babakhiqizi abahamba phambili nabathumela ngaphandle kwezinhlobonhlobo eziningi ze-Cast Iron Pulleys.Lawa ma-pulley akhiqizwa kusetshenziswa impahla eluhlaza yezinga eliphezulu, ethengwa kubathengisi abathembekile bemakethe.Ngaphezu kwalokho, sinikeza lawa ma-pulleys ezigabeni ezihlukahlukene ezifana no-a, b, kanye no-c.Okulandelayo ukucaciswa okuhlukahlukene komkhiqizo okunikezwa yithi

I-Cast Iron V-belt pulley "a" ingxenye [kusuka ku-1 groove kuya emiseleni emi-5]

Ingxube kasimende yezimboni esindayo ephonsa i-double groove pulley

I-Steel Rope Sheave Pulley iwuhlobo lwethuluzi elibalulekile lokuphakamisa, ilula ngesakhiwo, kulula ukuyisebenzisa.Ingashintsha

isiqondiso sokukhanga se-pulley kanye neqembu le-pulley, lingakwazi futhi ukuphakamisa nokuhambisa into esindayo, ikakhulukazi

iqembu le-pulley, kanye ne-winch, insika, nomunye umshini wokuphakamisa, osetshenziswa kabanzi ekwakheni.Ukucaciswa

ohlwini lwemikhiqizo kusuka ku-0.03t-320t.

I-Steel Rope Sheave Pulley isetshenziswa kakhulu kuMkhiqizi we-Crane, Isikhulu sechweba, umkhumbi, ukuphakamisa, umshini weloli, imishini yokwakha emikhulu,

Imboni nokunye.Intengo ingeyereferensi kuphela, sicela usithinte uma unesidingo.

| Igama lomkhiqizo | amasondo e-pulley | ||

| Okubalulekile | 45#,Q235B,Q235A,Q345A,Q345B,insimbi ye-alloy,i-carbon steel, njll (njengesicelo sekhasimende) | ||

| Iyacubungula | Ukugaya, ukugaya, ukugaya, ukubhoboza | ||

| Ukwelashwa kokushisa | Ukujwayela, ukwehlisa, ukuguga, ukuqina, nokuthambisa | ||

| I-Max.diameter | 5000mm | ||

| Ubude obukhulu | 8000mm | ||

| Ubukhulu.ukubekezelelana | ±0.2 | ||

| Ubukhulu.isisindo | 10T | ||

| Uhlobo | Ngokusho kwemidwebo | ||

| Ukuhlola | ukuhlolwa kobukhulu, ukuhlolwa kwemvelo yangaphandle, ukuhlolwa okubonakalayo, ukuhlolwa okungenayo, ukuhlolwa komkhiqizo oqediwe, ukutholwa kwamaphutha | ||

| Isikhathi sokuthumela | Izinsuku ezingama-30-90 | ||

I-Cast Iron Wheel Frame yama-Haulage Pulleys

Ividiyo ye-Cast Iron Wheel yama-Haulage Pulleys

I-GCS inelungelo lokushintsha ubukhulu nedatha ebucayi nganoma yisiphi isikhathi ngaphandle kwesaziso.Amakhasimende kufanele aqinisekise ukuthi athola imidwebo eqinisekisiwe evela kwa-GCS ngaphambi kokuphothula imininingwane yokuklama.

Ukukhethwa komthumeliroller

I-Conveyor rollerisetshenziselwa ukusekela ibhande lokuthutha kanye nezinto ezisebhande, ukunciphisa ukumelana nokusebenza kwebhande lokuthutha, ukuqinisekisa ukuthi i-sag yebhande lokudlulisa akudluli imithetho yezobuchwepheshe, futhi lenze ibhande lokuthutha lisebenze ngokushelela endleleni enqunywe kusengaphambili.

I-roller ngokuya ngokusetshenziswa kwayo ihlukaniswe ikakhulukazi i-carrier roller, i-return roller, i-impact roller kanye ne-roller yokuqondisa.I-roller ingenye yezingxenye ezibalulekile ezithinta ukusebenza komthumeli, ibalwa cishe ngama-30% ~ 40% wekhwalithi ye-conveyor yonke, 25% ~ 30% yenani lentengo yawo wonke umthumeli, futhi iyingxenye eyinhloko yansuku zonke. ukuphathwa, ukuvikelwa kanye nokushintshwa.Ukuhlelwa nokukhethwa kwe-roller kunethonya elibalulekile ekusebenzeni okujwayelekile komshini wokuthutha, umsebenzi ozinzile, ukusetshenziswa kwamandla kanye nenani le-conveyor yonke.Ikakhulukazi esimweni sejubane eliphezulu lebhande, izidingo ze-roller ziba nzima kakhulu.

Njengengxenye eyinhloko ye-conveyor, i-roller iye yaqina kakhulu ngokuthuthuka kwejubane lebhande.Izinto eziyinhloko ezithinta ukusebenza kwejubane eliphezulu kwerola inani eliphelayo kanye nenani lokumelana nokuzungezisa.Lapho i-roller isebenza ngesivinini esikhulu, isakhiwo sokuvala i-roller sizothinteka ngokushisa nezinye izizathu.Ukuhlelwa kwesakhiwo se-roller enesivinini esikhulu kuhlongozwa kuleli phepha.

1.Sealing isakhiworoller

Isakhiwo sokubeka uphawu siyisici esibalulekile esithinta impilo yokusebenza kanye nokumelana nokusebenza kwe-roller.Kunezindlela ezimbili eziyinhloko zesakhiwo sokuvala ama-roller emakethe:

(1) Uphawu olungathinteki (njenge-labyrinth seal).Ukumelana nokusebenza kwalolu hlobo lokubeka uphawu kuncane, kodwa ngenxa yokuba khona kokungqubuzana kwangaphakathi lapho usebenza ngesivinini esikhulu, nakanjani kuzoholela ekuveleni kokushisa.Ngokushintsha komfutho womoya, izinhlayiya zothuli zingena emgodini we-bearing seal kanye nenqubo yokuhogela, okubangela ukuthi i-bearing isebenze esimweni sokungqubuzana kokuphazamiseka, futhi kubhebhethekise ukuguga kwe-bearing.

(2) Thinta uphawu lohlobo.Umphumela wokuvala ungcono kunohlobo olungathinteki, kodwa ukumelana nokusebenza kukhulu.Endabeni yokushisa okukhulu nokwehluka kwengcindezi nokusabalalisa okungalingani, ukuguqulwa kwe-elastic yomlomo wokuvala nawo akuhambisani, okubangela umphumela omubi wokuvala.

Akulungile ukwengeza umphumela wokuvala kuphela ngokungeza inani lamaphaseji okuvalwa nobude bokuvala.Isakhiwo se-labyrinth sealing yegebe lokuqala elijikelezayo liyisihluthulelo sokubhekana nenkinga yokuvala, izinkinga zegebe, i-slime noma amanzi azogeleza esiteshini sangaphakathi se-labyrinth, okubangela ukwehluleka kwe-roller, inombolo enjalo ye-maze ayinangqondo.

I-roller ehlongozwayo kuleli phepha yamukela isakhiwo esiyinhlanganisela se-axial labyrinth seal kanye ne-touch seal, futhi izici zayo zimi kanje:

(1) Inombolo yamaphaseji okuvalwa kwe-axial labyrinth seal ayithinteki esikalini se-radial ye-bearing, futhi ingangezwa ngokufanelekile.Indawo evalekayo ye-axial labyrinth isendaweni efanayo namandla amaphakathi okugeleza kwamanzi.Amanzi angenile

uphawu lapho i-roller ijikeleza izogeleza iye phezulu kwe-labyrinth eduze kwendawo yokuvala ngaphansi komphumela wamandla we-centrifugal.Ukuze kuthuthukiswe umphumela, phezulu kwendandatho yangaphakathi yokuvala ingabhekwa njengokukhetha isakhiwo se-arc esiyindilinga.

(2) Faka indandatho yokuvala ohlangothini olungaphandle lwe-labyrinth seal ukuze wenze uphawu lokuthinta, olungakwazi ukubhekana kuphela "nenkinga yokuphefumula" ye-labyrinth seal, kodwa futhi ngeke ingeze ukujula kwesihlalo esithwalayo njenge ezinye izakhiwo ezihlanganisiwe zophawu.Indandatho yokuvala i-NBR/PA6, isisindo esilula, ukumelana nokugqwala, i-coefficient yokungqubuzana incane kunamanye amapulasitiki obunjiniyela.

(3) engeza indandatho ye-convex eringini ye-baffle yangaphakathi (bheka uMdwebo 1), shintsha isiqondiso sokunyakaza kwe-axial lapho uthuli noma amanzi kungena isikhala seringi ye-baffle yangaphakathi.Lapho i-roller isebenza ngesivinini esikhulu, kuzokwenziwa isivacu phakathi kweringi ye-convex nendandatho ye-baffle yangaphandle ukuze kuqinisekiswe umphumela wokuvala.

2.Izici zenqubo nokukhethwa kwezinto ezibonakalayo

Ukuphuma kwe-radial kwe-roller ngokuyinhloko kuncike ephutheni le-radial yesilinda, ikhwalithi yesihlalo esithwalayo kanye ne-coaxiality yenqubo yokuhlanganisa.Inani le-radial run-out le-roller linethonya elikhulu emsebenzini obushelelezi we-conveyor, ikakhulukazi uma inani le-radial run-out likhulu kakhulu ngesivinini esikhulu, ibhande lokudlulisa lizozulazula ngobudlova futhi lithinte umsebenzi ovamile.

Njengamanje, iningi lama-roller ama-rollers ashintshwa ngamapayipi ensimbi, anzima ngekhwalithi.Izinga lamapayipi, i-ovality kanye nokubekezelelana kobubanzi bangaphandle akulula ukuqinisekiswa, ikakhulukazi ukuba khona kokuyeka ukwakhiwa kwe-barrel kuthinta i-coaxiality, futhi kulula ukubangela ukuba ama-roller abe yi-eccentric.Ukudlidliza ngezikhathi ezithile kuzokwenzeka ngenxa yamandla e-centrifugal phakathi nenqubo yokusebenza, okuzothinta ukusebenza kahle kwebhande lokuthutha.

3. Ukukhetha okuthwala i-roller

Ukuphila kokusebenza kwe-roller ngokuyinhloko kuncike ekuthwaleni nasekufakweni uphawu.Abavilapha abaningi emakethe basebenzisa ama-bearings amakhulu.Uma kuqhathaniswa nama-bearings avamile, ama-bearings amakhulu ane-clearance enkulu nama-diameters ebhola, anganciphisa ukuzwela ku-coaxiality futhi athuthukise ikhono lokuzivumelanisa nezinto zangaphandle.

Kodwa-ke, ukukhethwa kwama-bearings ane-clearance enkulu kuzothinta kakhulu umthamo wokuthwala i-axial we-idler, ikakhulukazi ngemva kokunyuka kwejubane lebhande, ukunyakaza kwe-axial bearing umthamo kuzobangela isimo esingasebenzi esingalingani somthumeli webhande.Ngisho nasezikhathini ezinzima, kuyadingeka ukumisa umshini wokulungisa iphutha nokulungisa kabusha kusukela ekuqaleni.

Kuleli phepha, sihlela ukukhetha ama-deep groove ball bearings anesembozo sothuli, esingakwazi kuphela ukuqinisekisa ukuhlanzeka kwangaphakathi kwe-bearing, ukuthuthukisa umthamo we-axial bearing, ukunciphisa ukulimala okuvamile ekuthwaleni okubangelwa i-axial high-frequency. amandla omthelela, kodwa futhi uqinisekise ukusebenza okushelelayo kokuthwala kunweba impilo yangempela yokusebenza yebheringi.

Leli phepha lenze ucwaningo oluyisisekelo kuma-roller anesivinini esiphezulu kusukela ezicini zesakhiwo, ukuvala, ukusetshenziswa kanye nobuchwepheshe bezinto ezintsha.I-roller ithatha isakhiwo sokuvala esiyinhlanganisela esihlanganisa i-axial labyrinth kanye ne-touch labyrinth, futhi isebenzisa i-deep groove ibhola elinesembozo sothuli.Ukusetshenziswa kwezinto ezintsha kanye nokushintshwa kobuchwepheshe bokucubungula kuqinisekisa ukumelana nokujikeleza kwe-roller, ukugxuma kwe-radial circular kanye nokungangeni kwamanzi, ukuvala uphawu okungenathuli kanye neminye imisebenzi.Ngaphansi kokuqondisa kokuthuthukiswa kwamandla aphezulu, amabanga amade kanye nama-conveyors amakhulu, isakhiwo se-Roller esihlongozwayo kuleli phepha sinokuphikiswa okuncane okujikelezayo, umsindo ophansi nokuphila isikhathi eside sokusebenza, okudlala indima ebalulekile emandleni okukhipha isithuthi sejubane.

I-Global Conveyor Supplies Company Limited -RS series rollers

Umphini:I-roller shaft yenziwe ngensimbi eyindilinga enembayo enembayo enembayo, engazange ifudumale futhi ifudumale.Umshini wokugaya u-Precision chamfering, umshini wokugoqa indandatho usetshenziselwa ukucubungula i-shaft, ukuze kuqinisekiswe ukuthi ukususwa kwe-axial ye-roller cishe ku-zero.

Ishubhu:I-roller shaft yenziwe ngensimbi eyindilinga enembayo enembayo enembayo, engazange ifudumale futhi ifudumale.Igobolondo le-roller lamukela ipayipi le-welding ekhethekile, idigri encane yokugoba, ukunwebeka okuncane.Yamukela ipayipi lensimbi elithuthukisiwe lokusika i-chamfering kanye nethuluzi lomshini wembobo yangaphakathi, ukunemba komshini kuzo zombili iziphetho zepayipi lensimbi, qinisekisa ngempumelelo ukugxila kwe-roller, unciphise iphutha lomshini.

I-Bearing:I-roller bear ithatha i-C3 deep groove ball bearing ekhethekile.Ngaphambi kokuhlanganiswa, i-roller bear igcwaliswe ngamafutha e-lithium futhi ivalwe unomphela nhlangothi zombili, ekwazi ukubona ukugcinwa mahhala impilo yonke futhi yandise impilo yesevisi yokuthwala.

Ukuhlanganisa uphawu:Ingxenye ye-roller seal yenziwe ngezinto zenayiloni, futhi ifomu lesakhiwo liyi-contact labyrinth seal structure.Ukufakwa uphawu kwangaphakathi nangaphandle kwakha isiteshi se-labyrinth esinembayo esiphezulu, isiteshi esigcwele i-lithium grease yesikhathi eside, ukuze i-roller ibe nokusebenza okuhle okungangeni kwamanzi nothuli.Umshini wokugaya u-Precision chamfering, umshini wokugoqa indandatho usetshenziselwa ukucubungula i-shaft, ukuze kuqinisekiswe ukuthi ukususwa kwe-axial ye-roller cishe ku-zero.

Izindawo zokuhlala e- Bearing:Ukukhiqizwa kwezindlu ezithwalayo kusebenzisa ukubumba okuzenzakalelayo kwesitembu esinezitebhisi eziningi ukuze kuqinisekiswe ukunemba okuphezulu kokuthwala nokubeka uphawu.Amashubhu e-roller kanye nezindlu ezithwalayo kuzo zombili iziphetho I-3mm fllets egcwele ishiselwe ukuvikelwa kwegesi ye-carbon dioxide kanyekanye nomshini wokushisela othomathikhi wesibhamu okabili ukuze unikeze okungenani ukungena okungu-70% nokuqinisekisa ukuthi ukungenzi lutho kuhlala kuqinile ngisho nangaphansi kwemithwalo ephezulu nesivinini.

1. Amarola ochungechunge e-RS ayingxenye ye-GCS ephezuluukuhambisa ama-roller.

2. Irola yokubuya/yesithwali/umkhombe inokwakhiwa okunembayo okuphezulu okuhlanganisa izingxenye eziyisishiyagalolunye zokuvala, eziqinisekisa ukumelana kwamanzi nothuli okuhle kakhulu.Ngezigxivizo zenjoloba noma zensimbi, ama-multi-groove labyrinth seals.

3. Izindlu ezithwalayo kanye ne-roller tube zishiselwe ngokugcwele ukuze kuqinisekiswe ukuthintana okuhle kulo lonke i-roller.Igrisi iwukugcoba unomphela.

4. Ngokwezidingo zekhasimende, ingaphezulu le-roller lingapendwa nganoma yimuphi umbala.

5. Material: Ngokuvamile i-Q235 carbon steel (enikezelwe ekudluliseni i-roller), i-A3 i-shaft yokudweba ebandayo (ingaba ukunemba okuphezulu ngokusho kwezidingo ezahlukene zamakhasimende).

6. Irola ngayinye izodlula ekuhlolweni nasekuhlolweni okuqinile ukuze kuqinisekiswe ukuthi iqoqo ngalinye lerola liyikhwalithi ephezulu ngempela.

Sicela ukhululeke ukuxhumana nathi ukuze uthole ama-conveyor roller.

Singochwepheshe, ubuchwepheshe obuhle kakhulu kanye nenkonzo.Siyazi ukuthi ulenza kanjani umqulu wethu wokuthutha uhambise ibhizinisi lakho!Hlola okwengeziwewww.gcsconveyor.com I-imeyiligcs@gcsconveyoer.com

Amacala Aphumelele