What Are Rubber Conveyor Rollers ?

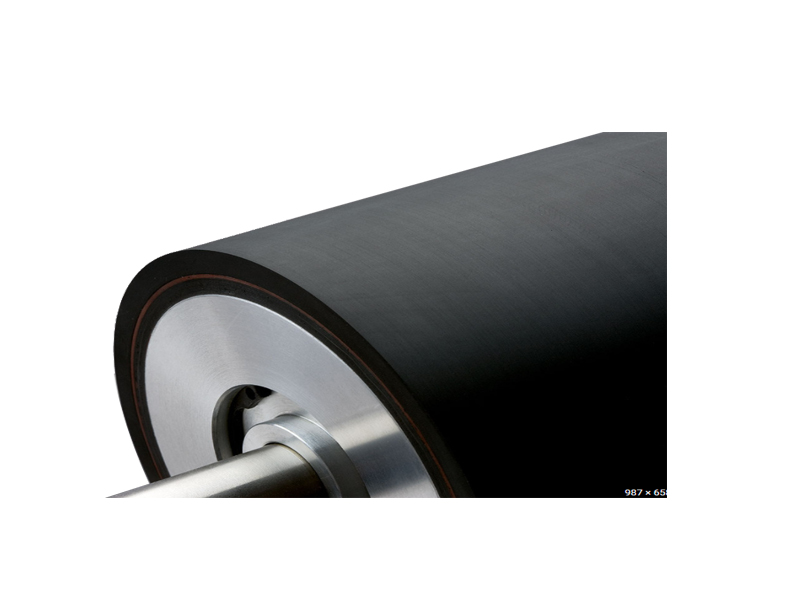

Rubber conveyor rollers are essential components in material handling systems. They consist of a core—typically made from metal or high-grade plastic—wrapped in a durable rubber cover. This combination offers several benefits: increased friction to prevent slippage, reduced noise and vibration for a quieter workspace, enhanced durability against wear and tear, and superior impact resistance to protect both the rollers and the conveyed materials. Whether you’re in food processing, logistics, or heavy industry, GCS rollers are designed to meet the demands of your specific application.

BUY CONVEYORS AND PARTS ONLINE NOW.

Our online store is open 24/7. We have various of conveyors and parts available at discount prices for fast shipping.

GCS Top 3 Hottest Rubber Rollers

What Are the Advantages of Rubber Conveyor Rollers ?

■ Enhanced Friction for Reliable Performance: The rubber coating on our rollers is designed to provide superior friction. This ensures that the conveyor belt adheres closely to the roller surface, minimizing the risk of slippage. For instance, in high-speed logistics operations where precise control is crucial, this enhanced friction allows for seamless movement of materials, even when dealing with heavy or uneven loads. The textured rubber surface increases the contact area between the roller and the belt, distributing pressure evenly and maintaining stability throughout the conveying process.

■ Noise and Vibration Reduction for a Quieter Workspace: Rubber is an excellent material for absorbing vibrations and dampening noise. In industrial settings, excessive noise can lead to a decrease in worker productivity and an increase in operational costs. GCS rubber conveyor rollers significantly reduce the noise generated by the movement of materials, creating a more pleasant and less disruptive environment for your team. This is particularly beneficial in settings such as distribution centers located near residential areas or in facilities where noise control is a priority.

■ Superior Corrosion and Wear Resistance for Longevity: Our rubber conveyor rollers are engineered to withstand harsh conditions. The rubber coating acts as a protective barrier against corrosive chemicals, moisture, and other environmental factors that can degrade metal components. In industries like chemical processing, where exposure to corrosive substances is common, this resistance ensures that the rollers maintain their integrity over an extended period. Additionally, the rubber surface reduces wear and tear on both the roller and the conveyor belt, as it minimizes friction and abrasion during operation.

■ Exceptional Impact Resistance for Durability: The elastic nature of rubber allows our rollers to absorb and distribute impact forces effectively. In applications where heavy or irregularly shaped items are being conveyed, this impact resistance prevents damage to both the roller and the materials being transported. For example, in recycling facilities where large pieces of scrap metal or plastic are moved along the conveyor, the rollers can withstand the constant bombardment without sustaining significant damage, ensuring consistent performance and reducing maintenance costs.

■ Customization Options to Meet Your Specific Needs: We understand that every conveying system is unique. That's why GCS offers extensive customization options for our rubber conveyor rollers. Whether you require a specific rubber hardness to match your application's demands, a particular surface texture for optimal belt adhesion, or a customized size to fit your existing infrastructure, we can deliver. Our team works closely with you to understand your operational challenges and design rollers that provide the perfect solution, ensuring maximum efficiency and reliability in your specific industrial context. Request your custom solution right now !

How Are Rubber Conveyor Rollers Constructed ?

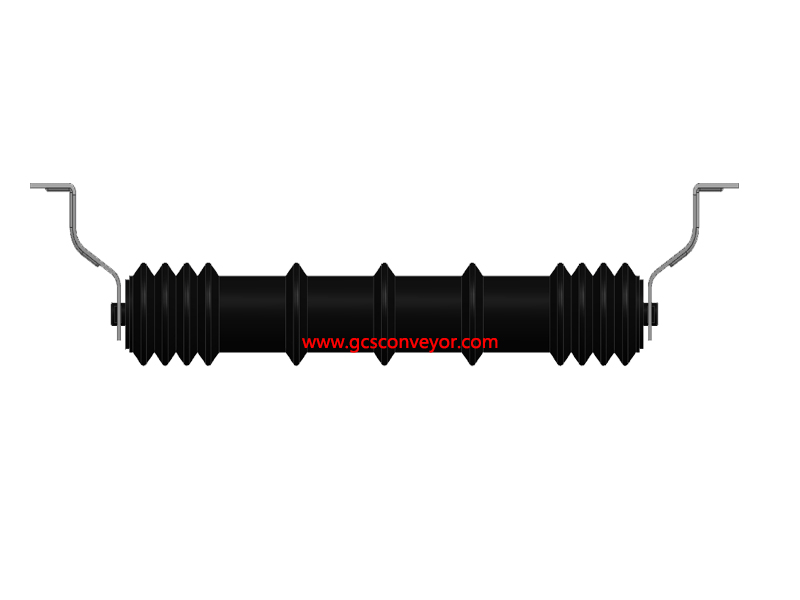

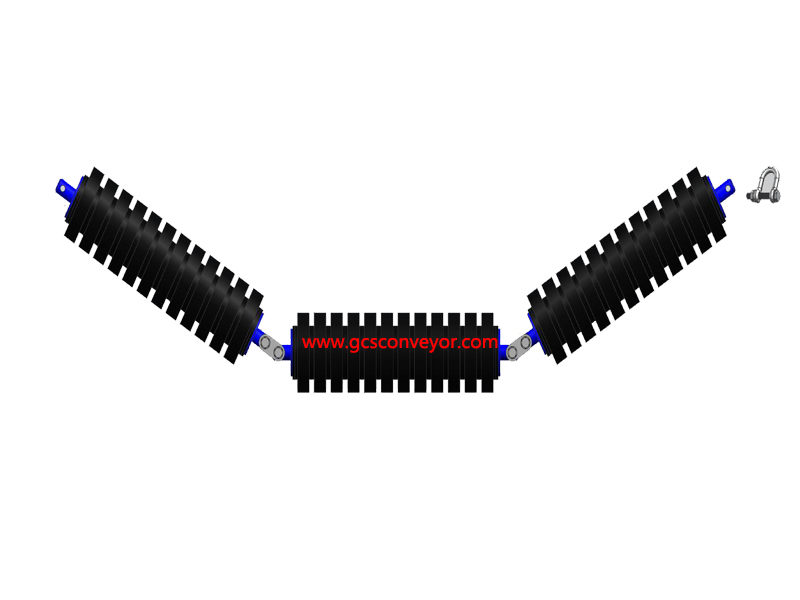

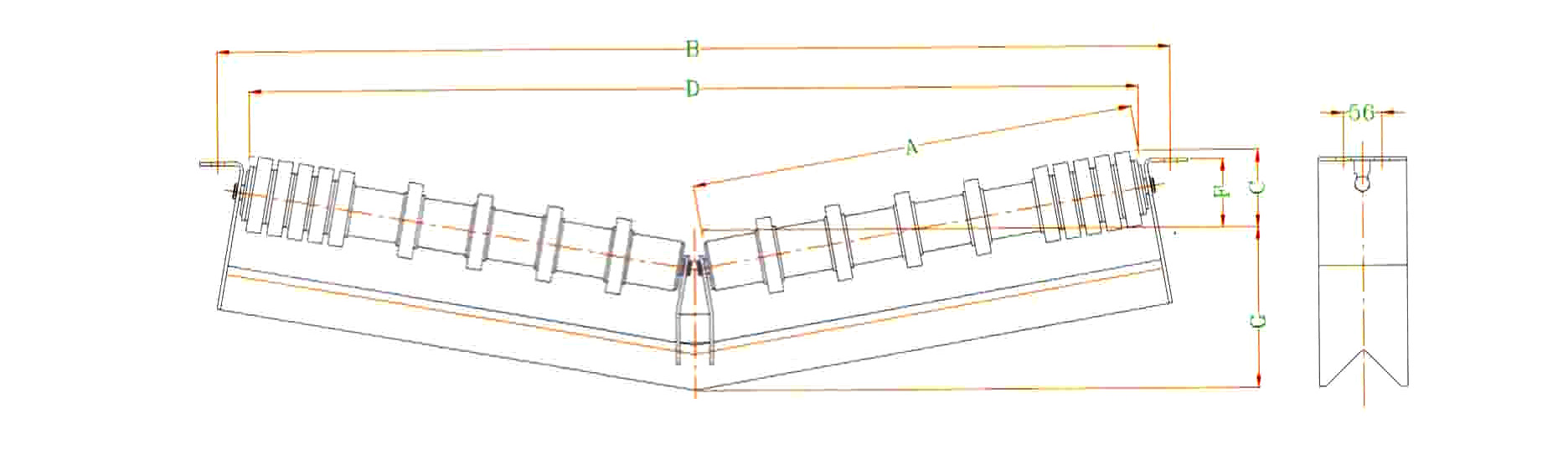

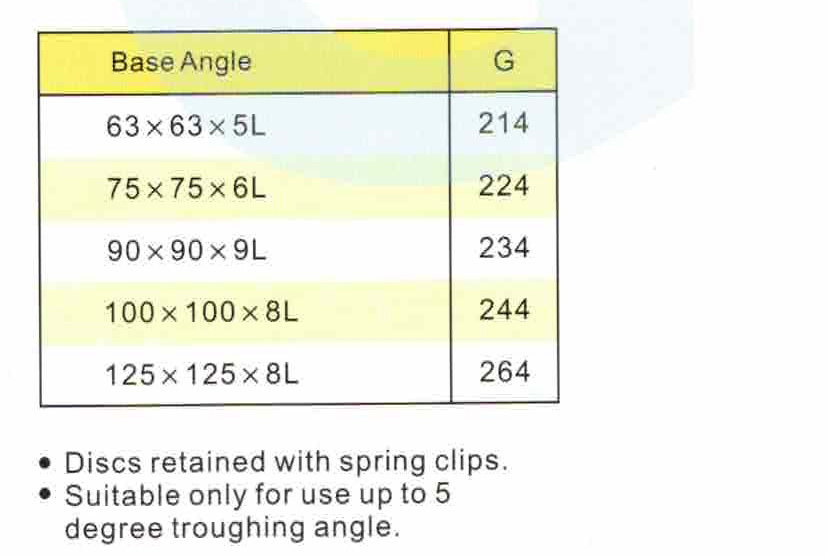

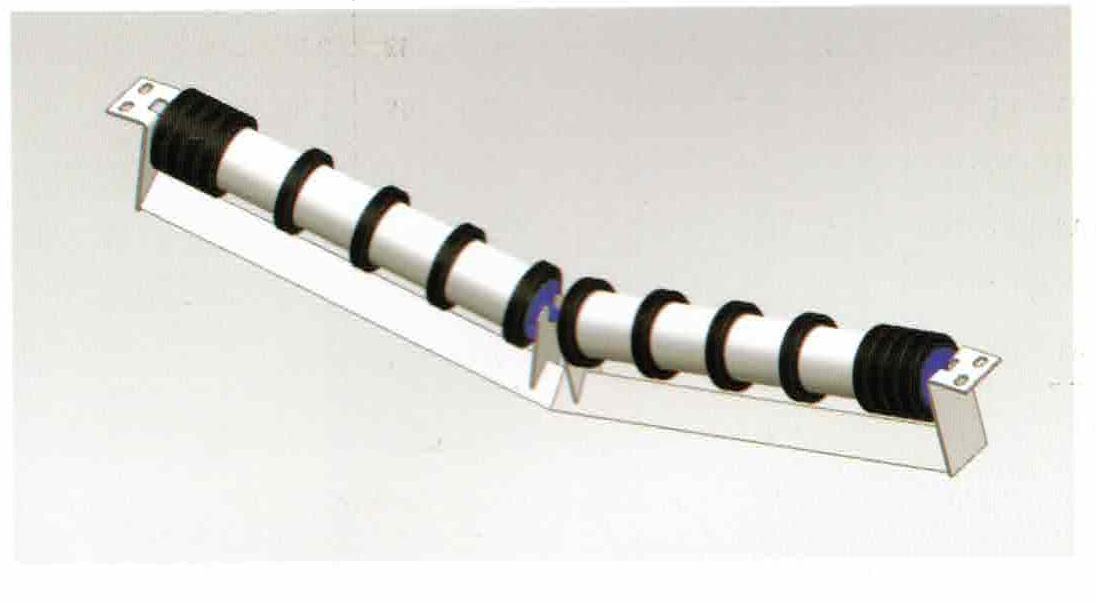

Rubber Disc Vee Return Idler Without Space 127 Diameter

The Rubber Disc Vee Return Idler consists of a high-strength carbon steel roller body, wear-resistant rubber discs, a V-shaped bracket, precision bearings, and a multi-seal system. The rubber discs are spaced in the middle to effectively remove adhered material, while tightly grouped at both ends to protect the belt edges. The V-shaped structure ensures belt alignment and prevents deviation. Equipped with deep groove ball bearings and a multi-labyrinth sealing system, it is dustproof and waterproof for extended service life.

What Are the Rubber Conveyor Rollers Manufacturing Process and Quality?

At GCS, we pride ourselves on our state-of-the-art manufacturing processes. From precision rubber formulations to final assembly, every step is meticulously controlled to ensure the highest quality. Our rollers undergo rigorous testing to meet industry standards and exceed your expectations. Key features include:

●Integrated Bearings: Designed to reduce friction and enhance longevity.

●Anti-Static Treatments: Ideal for sensitive environments like electronics manufacturing.

●High Load Capacity: Reinforced structures to support heavier loads without compromising performance.

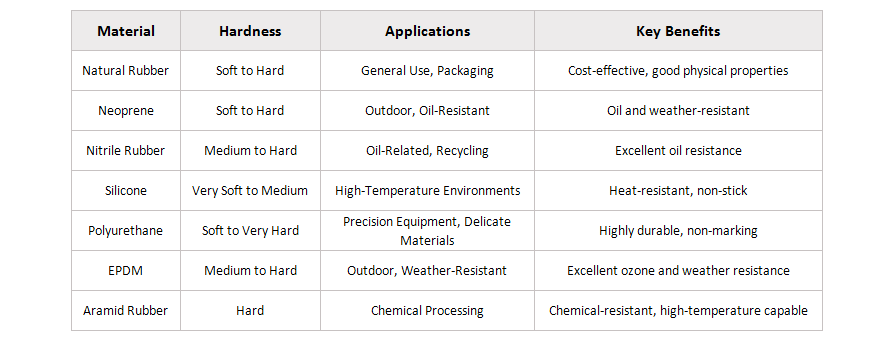

Material Options of Rubber Conveyor Rollers

Comparision of Rubber Conveyor Rollers:

Application Scenarios of Rubber Conveyor Rollers

■ Logistics & Warehousing

Rubber conveyor rollers are essential in logistics hubs, e-commerce fulfillment centers, and automated warehouses. Their shock-absorbing and noise-reducing properties ensure smooth and quiet operations, crucial for high-speed sorting systems. Heavy-duty rubber rollers protect conveyor belts and packages, minimizing downtime and maintenance costs.

■ Mining & Bulk Material Handling

In mining, quarrying, and cement industries, Rubber Disc Vee Return Idlers prevent material buildup and misalignment, ensuring continuous and stable operations. These rollers withstand harsh environments, including dust, moisture, and heavy loads, reducing wear and extending conveyor life.

■ Food & Beverage Processing

Rubber-coated rollers offer gentle handling of packaged and unpackaged food products. They resist water, oils, and chemicals, ensuring hygiene compliance in food processing plants. Their smooth, non-stick surface helps prevent contamination and product damage.

■ Manufacturing & Heavy Industry

From automotive to steel production, rubber conveyor rollers are used in assembly lines and material transport systems. Their durability and high load capacity make them suitable for handling metal parts, machinery, and raw materials.

■ Airports & Baggage Handling

In airport conveyor systems, rubber rollers ensure smooth luggage transport, reducing wear on conveyor belts and providing reliable performance under constant operation.

Conclusion

A rubber roller is a machine part that is composed of an inner round shaft or tube covered by an outer layer of elastomer compounds.

Rubber rollers take advantage of the desirable properties of elastomers, such as impact strength, shock absorption, abrasion resistance, high coefficient of friction, and controllable degree of hardness.

The two main parts of a rubber roller are the roller core and the rubber cover. The roller core is the main structural component connected to the main drive unit. On the other hand, the rubber cover is the component that is pressed against the load.

Manufacturing of a rubber roller is a straightforward process involving the fabrication of the roller core, rubber compounding, bonding, covering, vulcanizing, grinding, and balancing.

Partnering with GCS

When you choose GCS, you’re not just buying a product—you’re gaining a partner. From initial consultation and custom design to ongoing support and maintenance, we’re here to ensure your conveying system runs at peak performance.We look forward to being a part of your success. Have questions? Need a quote? Reach out to us anytime. Our staff are ready to help.