Custom roller conveyors most need to pay attention to which conveyors.

Conveyor Roller Manufacturer,factory In China

If your specifications do not meet our standard products, we can tailor a solution to your needs. For high-volume products, we can also discuss developing unique products.

As a 45–year–old conveying equipment conveyor roller manufacturer(GCS), We specialize in this field for more than 45 years, with high quality and a pretty competitive price.

Roller conveyor line definition

The use of roller and roller easy to connect, the composition of roller conveyor line, can be more than one roller line and other conveyor or special machine to form a complex logistics conveyor system, to complete a variety of process needs. An accumulation roller can be used to realize the accumulation of materials. The roller conveyor/roller conveyor line/roller assembly line has a simple structure, high reliability, and easy maintenance. It is suitable for conveying all kinds of boxes, bags, pallets, and other goods, and can convey single pieces of materials with large weight or bear large impact load, with large conveying capacity, fast speed, light operation, and can achieve the characteristics of multi-varieties of common line shunt conveying.

Choose Your Conveyor Idler Rollers

Global Conveyor Supplies Company Limited (GCS) conveyor rollers suppliers specialized in manufacturing and selling various idlers for bulk material conveying idler equipment, galvanized rollers for light industrial continuous conveying equipment, roller conveying systems, spare parts, and related peripheral hardware products.

It also has obtained an ISO9001:2015 quality management system certificate. Our company obtained the industrial production license issued by the General Administration of Quality Supervision.

Products-ROLLER CONVEYOR

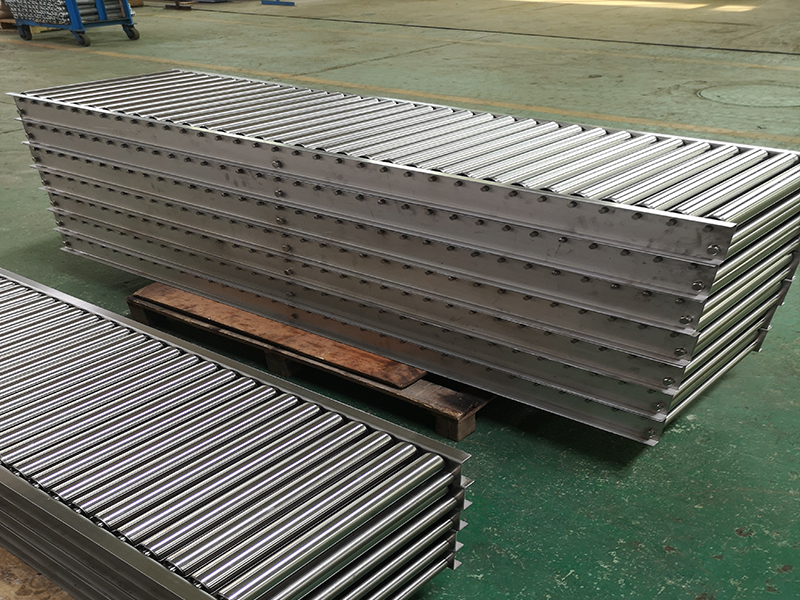

The roller conveyor consists of three basic components: a frame, a bearing drum, and a support. These devices can be equipped with feet or casters and include parking brakes for different positions. The roller conveyor can be extended indefinitely with the help of connecting elements, and the height of the roller conveyor can also be adjusted using adjustable H-shaped supports.

In addition to the necessary components, the PU gravity roller of the roller conveyor can be used to protect the conveyor itself and the conveyed goods in specific requirements. The use of PU over steel gravity rollers has a win-win advantage in terms of cost and effectiveness.

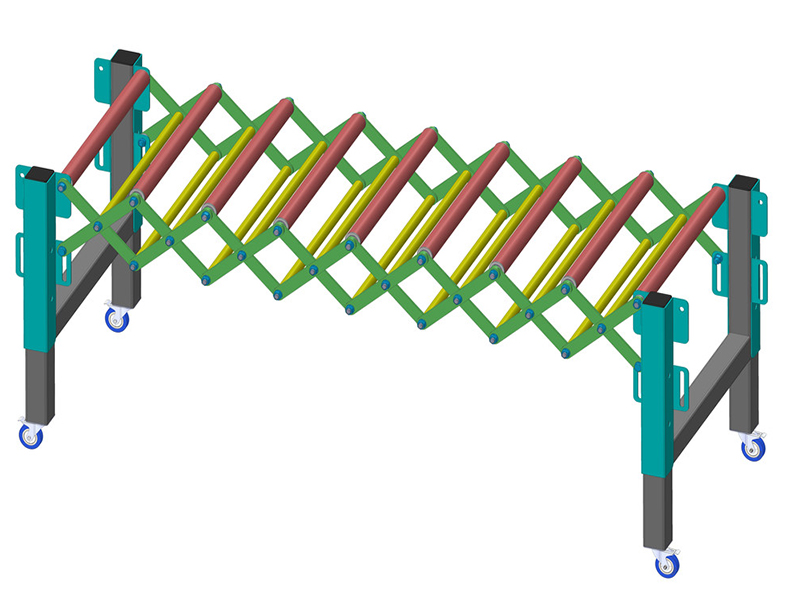

Flexible gravity roller conveyor

Flexible conveyors can be bent into a variety of configurations for delivery to multiple loading docks. Flexible conveyor solutions reduce the number of operators, increase speed, improve ergonomics and safety, and increase loading and unloading efficiency.

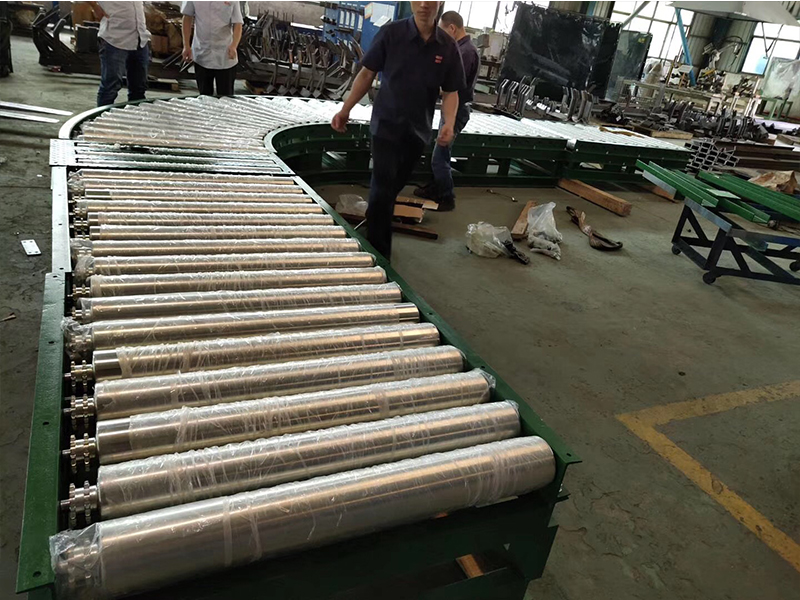

Drive sprocket roller curve conveying system by GCS conveyor roller chain manufacturers

The conveyor is a continuous transfer mechanism that allows the transfer of any material from one end to the other. The movement of the conveyors can be achieved by motor power, manpower, and gravity.

We are the leading manufacturer of gravity roller conveyors. Gravity Roller Conveyors are the most economical and common method of conveying unit loads. Gravity Roller Conveyors are typically mounted on a slight decline angle, therefore using gravity to assist product movement, especially for long distances. Gravity Roller Conveyor can also be used in applications where the conveyor is level and operators can push the product along to its final destination.

Flexible gravity roller conveyor

Flexible conveyors can be bent into a variety of configurations for delivery to multiple loading docks. Flexible conveyor solutions reduce the number of operators, increase speed, improve ergonomics and safety, and increase loading and unloading efficiency.

Don’t you find what you are looking for?

Just tell us your detailed requirements. The best offer will be provided.

Your Top Conveyor Roller Supplier And Manufacturer

GCS is a company on design and manufacturing experience of conveyor roller for more than 26 years, GCS adopts advanced technology in its manufacturing operations to implement automatic mechanical production: Automated mechanical roller line, drumline, bracket line: CNC machine tools; Automatic welding robot arm; CNC automatic tapping machine; Data control punching machine; shaft processing line; Metal stamping production line.

Roller conveyor Flexible belt O belt roller

Bandwidth:400/500/550/600/650/700

Overall length:1000mm/1500mm/

Surface default roller galvanizing/stand paint and baking paint

Pack up/unfold

Support height

Advantages Of Products

Have a Special Requirement?

Generally, we have common conveyor roller products and raw materials in stock. For your special demand, we offer you our customization service. We accept OEM/ODM.

Why Choose Us As Your Conveyor Roller Supplier In China

Product quality control

1, the product manufacturing and testing are quality records and testing information.

2, the product performance testing, we invite the user to visit the product in the whole process, the whole performance check, until the product was confirmed after the shipment.

Materials choosing

1, in order to ensure high reliability and advanced products, the system selection are selected domestic or international quality brand-name products.

2, in the same competitive conditions, our company is not to reduce the technical performance of products, change the cost of product components on the basis of sincere to the most preferential prices available to you.

Promise for delivery

1, product delivery: as far as possible according to user requirements, if there are special requirements, to be completed ahead of schedule, our company can be specially organized production, installation, and strive to meet user needs.

Frequently Asked Questions

A:T/T or L/C. Other payment term we can also discuss.

A:We support customization according to your request.

A: 1 piece

A: 5~20 days.We always prepare enough raw materials for your urgent needs, we will check with our production department for nonstock products, to provide you with the exact delivery time and production schedule.

A:We are the 100% manufacturer ,could guarantee the first-hand price.

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

Conveyor Roller-The Ultimate Guide

Roller conveyors are often used in environments such as warehouses or manufacturing facilities due to the nature of the goods being transported. Roller conveyors can add versatility to transfer, diverter, and stop types and can be used as part of a conveyor system or automated system.

The use of roller conveyors can add versatility to transfer, diverter, and stop types and can be used as part of a conveyor system or automated system.

While proper design and selection will be fundamental to the smooth use of a conveyor and the beginning of the problem, GCS has many years of relevant experience to share with you.

Features Of Conveyor Roller

Different Types Of Idler Rollers

There are two types of idler rollers: carrying idlers and return idlers. They are located on the support side and return side of the conveyor. These idlers have many types and functions due to specific applications.

Application Of Conveyor Roller

The products are widely used in coal mines, metallurgy, machinery, ports, construction, electricity, chemistry, food packing and other industries. It endures over 70% resistance of one belt conveyor. The conveyor roller(idler) is used for supporting conveyor belt and the material . There are many kinds roller that we supply, like steel, nylon, ceramic or rubber.

We are committed to producing high quality metal conveyor rollers.

In mining industry, we can see heavy duty conveyor rollers everywhere. It is efficient to use this helpful tools.

Our aluminum conveyor rollers product is hot-selling item in our factory. Not only durable but also beautiful.

Our precision conveyor rollers are widely used all over the world, which are reliable and quality assurance.

Conveyor industry resources for engineers

Structural Design and Criterion of Roller Conveyor

The roller conveyor is suitable for conveying all kinds of boxes, bags, pallets, etc. Bulk materials, small items, or irregular items need to be transported on pallets or in turnover boxes.

Pipe belt conveyor and application scenarios

The pipe conveyor has a wide range of applications. It can transport materials vertically, horizontally, and obliquely in all directions. And the lifting height is high, the conveying length is long, the energy consumption is low, and the space is small.

GCS belt conveyor types and application principle

Common belt conveyor structure in various forms, climbing belt machine, tilt belt machine, slotted belt machine, flat belt machine, turning belt machine and other forms.

Our other manufacturing services

Contact us for information on idler roller dimensions,conveyor idler specifications, conveyor idlerscatalogue and price.