One of Hottest for Rubber Idler Rollers - Conveyor Pulleys for Lagging – Vulcanized in Belt Conveyor – GCS

One of Hottest for Rubber Idler Rollers - Conveyor Pulleys for Lagging – Vulcanized in Belt Conveyor – GCS Detail:

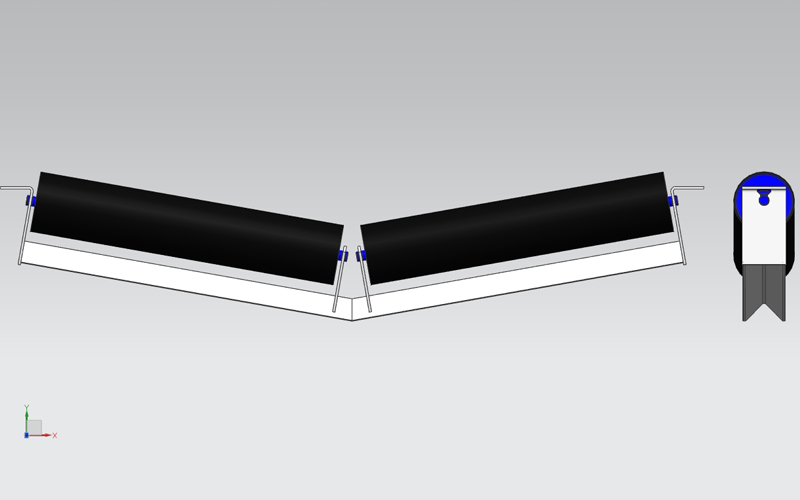

The drive pulley is the component that transmits power to the conveyor. The Pulley surface has smooth, lagged, and cast rubber, etc., and the rubber surface can be divided into rubber covered with herringbone and diamond. The herringbone rubber-cover surface has a large friction coefficient, good slip resistance, and drainage, but is directional. Diamond rubber-cover surface is used for conveyors that run in both directions. From the material, there are steel plate rolling, cast steel, and iron. From the structure, there is assembly plate, spoke and integral plate types.

The bend pulley is mainly under the belt. If the belt conveying direction is left, the bending roller is on the right side of the belt conveyor. The main structure is the bearing and the steel cylinder. The drive pulley is the drive wheel of the belt conveyor. From the relationship between the bend and drive pulley, it is like two wheels of the bicycle, the rear wheel is the drive pulley, and the front wheel is the bend pulley. There is no difference in the structure between the bend and drive pulley. They are composed of the main shaft roller bearing and the bearing chamber.

GCS(conveyor idler manufacturers) pulley quality inspection mainly checks the shaft quenching and high temperature tempering, weld line ultrasonic flaw detection, rubber material and hardness, dynamic balance test, etc. to ensure product working life.

Different kinds of conveyor pulleys

Our (GCS)conveyor pulleys in all the following sub-categories:

Head pulleys

The head pulley is located at the discharge point of the conveyor. It usually drives the conveyor and often has a larger diameter than other pulleys. For better traction, the head pulley is usually lagged (with either rubber or ceramic lagging material).

Tail and wing pulleys

The tail pulley is located at the loading end of the belt. It comes with either a flat face or a slatted profile (wing pulley), which cleans the belt by allowing material to fall between the support members.

Snub pulleys

A snub pulley improves the traction of the drive pulley, by increasing its belt wrap angle.

Drive pulleys

Drive pulleys, which can also be the head pulley, are driven by a motor and power transmission unit to propel the belt and material to the discharge.

Bend pulleys

A bend pulley is used for changing the direction of the belt.

Take-up pulley

A take-up pulley is used to provide the belt with the proper amount of tension. Its position is adjustable.

|

Shell Dia (Φ) |

250/215/400/500/630/800/1000/1250/1400/1600/1800(Customized) |

|

Length(mm) |

500-2800(Customized) |

Related product

Conveyor Drum Pulley For Heavy-Duty Conveyor

Drive Conveyor Pulleys For Conveyor Head Pulley

Rubber Lagged Drum Pulley by GCS

Product detail pictures:

Related Product Guide:

It is our responsibility to meet your needs and efficiently serve you. Your satisfaction is our best reward. We are looking forward to your visit for joint growth for One of Hottest for Rubber Idler Rollers - Conveyor Pulleys for Lagging – Vulcanized in Belt Conveyor – GCS , The product will supply to all over the world, such as: Swansea, Durban, Chile, We have now a good reputation for stable quality goods, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.