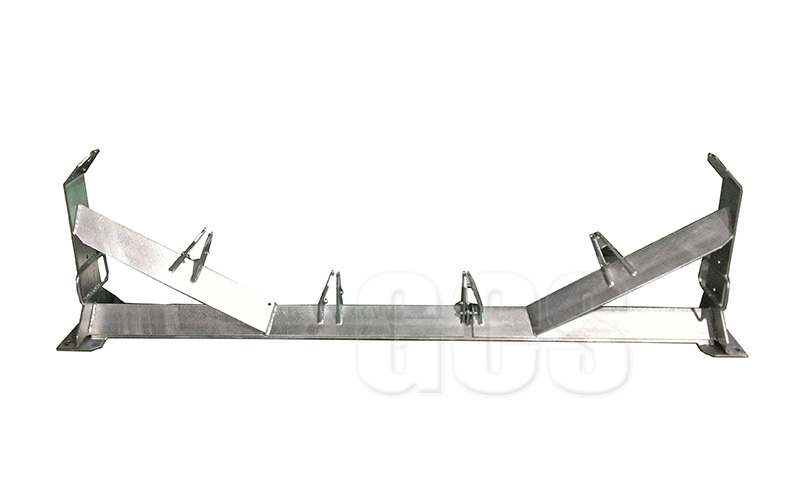

Metal Conveyor Roller Support Frame Bracket

Conveyor Roller Brackets

GCS manufactures various products including different types of conveyor rollers, impact rollers, belt /spiral roller/cleaners for both light and heavy-duty use in the chemical industry together with various molds, fabrications, and metal stamping products, press bearings, universal balls, foot cups, and accessories.

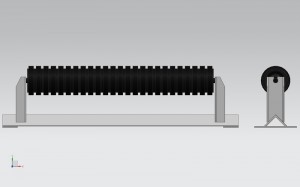

Conveyor belt rollers, which are manufactured in accordance with the audiences for certification GB 10595-89 (belt conveyor specification), issued by The People's Republic of China, can be designed to suit the

customers' specific requirements. In addition, they can be manufactured to conform to the national and

regional standards of Japan, Australia, and other countries. Standard widths for conveyor belts are

500mm, 650mm, 880mm, 1000mm, 1200mm, 1400mm, 1600mm, 1800mm, 2200mm, 2400mm etc.

(all included with the standard roller table).

Rollers in excess of 1400 mm can be manufactured in accordance with customers' own specifications.

Diameters (mm) of the rollers for heavy duty use are: 63.5, 76, 89, 102, 108, 114, 127, 133, 140, 152, 159,165 and 194 etc.

Diameters (mm) of the rollers for both the chemical industry and light-duty use are 25, 28.38.42.48.50.57.6.63.5.70.76.80, and 89. Lengths will be tailored exactly 10 to meet customer requirements.

Optimize its process on Roller Bracket and Frame

: the factory produces trough roller support, V-type return support, ring roller support, and suspension type support, using semi-automatic CNC high equipment, to achieve the most perfect state, more accurate reduction of tolerance value. Effectively improve production capacity, to provide customers with more effective services.

| Production Name | Belt conveyor roller bracket |

| Belt Width | 450 500 600 650 750 800 900 1000 1050 1200 1350 1400 1500 1800 2000 2400 mm |

| Materials | Q235 carbon steel, stainless steel |

| Type | DTII, TD75, aligning |

| Degree | Customized, like 10 20 30 35 45 10±5 20±5 |

| Welding | Automatic welding |

| Surface | Electrostatic spray painting galvanized |

Main Feature

1) Solid design, suitable for heavy lifting.

2) The bearing housing and steel tube are assembled and welded with a concentric automatic.

3) Cutting of the steel tube and bearing is performed with the use of a digital auto device/machine/equipment..

4) The bearing end is constructed to ensure that the roller shaft and bearing can be firmly connected.

5) Fabrication of the roller is effected by an auto device and 100% tested for its concentricity.

6) Roller and supporting components/materials are manufactured to DIN/ AFNOR/ FEM/ ASTM/ CEMA standard.

7) The casing is manufactured with highly composite, anti corrosive alloy.

8) The roller is lubricated and free from maintenance.

9) Woring life expectancy is up to 30,000 hours or more, depending on usage.

10)Vacuum sealed which has withstood anti water, salt, snuff, sandstone and dust proof experiments

Related Products

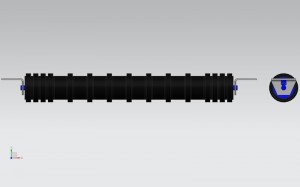

Conveyor roller manufacturers by Global Conveyor Supplies(GCS)

GCS has them in stock with standard diameters of 76mm,89mm,102mm, 114mm, 127mm, 152mm and 178mm,193mm. GCS can also design and manufacture rollers to customers’ specifications where non-standard rollers are required and ship worldwide.

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.