Inline Transition Idlers wholesale

GCS-Weigh Quality Roller Idlers |GCS

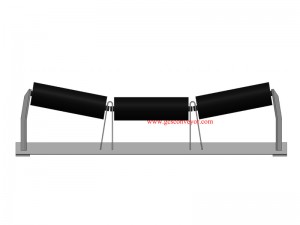

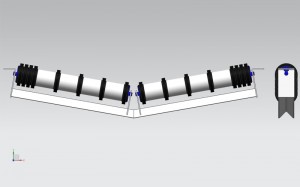

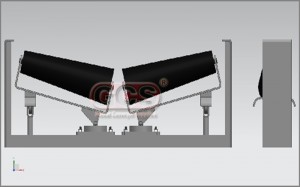

Transition idlers are located at both ends of the conveyor, near the head and tail pulleys. These roller sets include standard rollers, but the base on which these rollers are mounted has a smaller trough angle compared to the rest of the rollers/carriers on the conveyor.

The reason for this is that the conveyor belt is flat as it passes over the pulleys at high tension. When the belt changes its shape to a full groove, e.g. 35 degrees (i.e. from the tail pulley to the full groove angle), the belt has to be supported through this transition area. If the belt is fed directly from the trailing pulley into the full groove, the belt edges will be overstressed and damage will result. Similarly, when the slot angle becomes zero at the head end, the transition rollers provide support through the transition zone. The number of transition rollers required depends on the slot angle of the conveyor. Standard roller types are available as part of the GCS roller range.

To send us your exact idler specification, please hover over the technical specifications button below to display our idler frame inquiry form, which you can fill in and send directly to us by email (click here).

The transition idler is arranged between the end roller and the trough idlers to reduce the stress on the edge of the conveyor belt and avoid the occurrence of material sprinkling. The trough angle is divided into 10°, 20°, 30°, and variable angles.

| BW | B800-B2400 |

| Pipe Dia | D89-D218 |

GCS-Flexible Roller Conveyors video

GCS-Roller Type

GCS conveyor belt system manufacturers reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.