Cam khwb cia hlau log ncej rau Haulage Pulleys

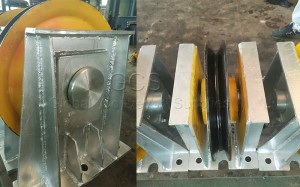

V-Belt Casting Pulleys

Peb yog ib qho ntawm cov tuam txhab ua lag luam thiab cov xa tawm ntawm ntau yam Cast Iron Pulleys. Cov pulleys no yog tsim los siv cov khoom siv qib siab, uas tau txais los ntawm cov neeg muag khoom txhim khu kev qha ntawm lub khw. Ntxiv mus, peb muab cov pulleys nyob rau hauv ntau seem xws li a, b, thiab c. Hauv qab no yog ntau yam specifications ntawm cov khoom muab los ntawm peb

Cam khwb cia hlau V-siv pulley "a" ntu [los ntawm 1 zawj mus rau 5 zawj]

Heavy-duty industrial cement tov khoom casting ob chav groove pulley

Hlau Rope Sheave Pulley yog ib yam ntawm cov cuab yeej tseem ceeb hoisting, nws yooj yim hauv cov qauv, siv tau yooj yim. Nws tuaj yeem hloov tau

qhov attraction kev taw qhia ntawm lub pulley thiab pab pawg neeg pulley, nws tseem tuaj yeem nqa thiab txav cov khoom hnyav, tshwj xeeb tshaj yog cov

Pulley pawg, ua ke nrog winch, mast, thiab lwm lub tshuab nqa, dav siv hauv kev tsim kho. Cov specification

ntawm cov khoom npe los ntawm 0.03t-320t.

Hlau Rope Sheave Pulley yog dav siv nyob rau hauv Crane Chaw tsim tshuaj paus, Chaw nres nkoj cai, Nkoj, Hoist, Truck crane, loj-scale siv machinery,

Kev lag luam thiab lwm yam. Tus nqi yog rau siv xwb, thov hu rau peb yog tias koj muaj kev xav tau.

| Khoom npe | lub log tsheb | ||

| Khoom siv | 45 #, Q235B, Q235A, Q345A, Q345B, alloy steel, carbon steel, thiab lwm yam (Raws li cov neeg siv khoom thov) | ||

| Kev ua haujlwm | Lathing, milling, sib tsoo, drilling | ||

| Kev kho cua sov | Normalizing, annealing, aging, hardening, thiab tempering | ||

| Max. txoj kab uas hla | 5000 hli | ||

| Max. Ntev | 8000 hli | ||

| Max. kam rau ua | ± 0.2 | ||

| Max. hnyav | 10 T | ||

| Hom | Raws li kev kos duab | ||

| Kev tshuaj xyuas | Dimension soj ntsuam, kuaj ib puag ncig sab nraud, kuaj pom, tshuaj xyuas tuaj, tshuaj xyuas cov khoom tiav, kuaj pom qhov tsis haum | ||

| Lub sij hawm xa tuaj | 30-90 hnub | ||

Cam khwb cia hlau log ncej rau Haulage Pulleys

Video of Cast Iron Log for Haulage Pulleys

GCS muaj cai hloov qhov loj me thiab cov ntaub ntawv tseem ceeb txhua lub sijhawm yam tsis muaj ntawv ceeb toom. Cov neeg siv khoom yuav tsum xyuas kom meej tias lawv tau txais daim ntawv pov thawj los ntawm GCS ua ntej ua tiav cov ntsiab lus tsim.

Kev xaiv ntawm conveyorcov menyuam

Conveyor rolleryog siv los txhawb nqa txoj siv conveyor thiab cov ntaub ntawv ntawm txoj siv, txo qhov kev ua haujlwm ntawm txoj siv conveyor, xyuas kom meej tias lub sag ntawm txoj siv conveyor tsis tshaj cov kev cai, thiab ua rau txoj siv conveyor ua haujlwm zoo nyob rau hauv cov kev taw qhia ua ntej.

Cov menyuam yaus raws li nws txoj kev siv feem ntau yog muab faib ua cov menyuam nqa khoom, rov qab cov menyuam, cuam tshuam rau cov menyuam thiab cov menyuam sib dhos. Cov menyuam yog ib qho tseem ceeb uas cuam tshuam rau kev ua haujlwm ntawm cov khoom siv conveyor, suav txog li 30% ~ 40% ntawm tag nrho cov khoom zoo, 25% ~ 30% ntawm tus nqi ntawm tag nrho cov conveyor, thiab nws yog thawj feem ntawm kev tswj txhua hnub, kev tiv thaiv thiab hloov. Kev npaj thiab xaiv cov menyuam muaj ib qho tseem ceeb ntawm kev ua haujlwm ntawm lub conveyor, kev ua haujlwm ruaj khov, kev siv hluav taws xob thiab tus nqi ntawm tag nrho cov conveyor. Tshwj xeeb tshaj yog nyob rau hauv cov ntaub ntawv ntawm kev siv ceev ceev, cov kev cai ntawm cov menyuam yuav ua ntau nruj.

Raws li qhov tseem ceeb ntawm cov khoom siv conveyor, cov menyuam tau dhau los ua nruj dua nrog kev nce qib ntawm txoj siv ceev. Lub hauv paus tseem ceeb cuam tshuam rau kev ua haujlwm siab ceev ntawm cov menyuam yog cov nqi khiav tawm thiab cov nqi sib hloov. Thaum cov menyuam ua haujlwm ntawm kev kub ceev, lub sealing qauv ntawm cov menyuam yuav raug cuam tshuam los ntawm tshav kub thiab lwm yam laj thawj. Cov qauv kev npaj ntawm high-speed roller yog npaj rau hauv daim ntawv no.

1.Sealing structure ntawmroller

Cov qauv sealing yog qhov tseem ceeb cuam tshuam rau lub neej ua haujlwm thiab kev ua haujlwm ntawm cov menyuam. Muaj ob txoj hauv kev tseem ceeb rau kev sib khi cov qauv ntawm cov menyuam hauv khw:

(1) Tsis-kov foob (xws li labyrinth foob). Kev ua hauj lwm tsis kam ntawm qhov kev sib khi no yog me me, tab sis vim muaj qhov tsis sib haum xeeb sab hauv thaum ua hauj lwm ntawm kev kub ceev, nws yuav inevitably ua rau qhov tshwm sim ntawm tshav kub. Nrog rau kev hloov pauv ntawm huab cua siab, cov plua plav plua plav nkag mus rau hauv cov kabmob ntsaws kab noj hniav nrog rau cov txheej txheem nqus pa, ua rau cov kabmob ua haujlwm nyob rau hauv lub xeev ntawm kev cuam tshuam tsis sib haum xeeb, thiab ua rau hnyav hnyav ntawm cov kabmob.

(2) Kov hom foob. Cov nyhuv sealing zoo dua li hom tsis kov, tab sis kev ua haujlwm tsis zoo yog qhov loj. Nyob rau hauv cov ntaub ntawv ntawm qhov kub thiab txias sib txawv thiab tsis sib xws, elastic deformation ntawm daim di ncauj sealing kuj tsis sib haum, ua rau cov nyhuv sealing tsis zoo.

Nws tsis yog qhov zoo tshaj los ntxiv cov nyhuv sealing nkaus xwb los ntawm kev ntxiv cov lej sealing thiab sealing ntev. Lub labyrinth sealing qauv ntawm thawj rotating qhov sib txawv yog tus yuam sij los daws qhov teeb meem sealing, cov teeb meem sib txawv, slime los yog dej yuav ntws mus rau hauv lub labyrinth channel, ua rau tsis ua hauj lwm ntawm cov menyuam, xws li maze tooj yog tsis muaj nuj nqis.

Cov menyuam uas tau thov hauv daim ntawv no lees txais cov qauv sib xyaw ntawm axial labyrinth foob thiab kov foob, thiab nws cov yam ntxwv yog raws li hauv qab no:

(1) Tus naj npawb ntawm kev sib khi ntawm lub axial labyrinth foob tsis cuam tshuam los ntawm qhov ntsuas radial ntawm cov kabmob, thiab tuaj yeem muab ntxiv kom tsim nyog. Lub sealing nto ntawm axial labyrinth yog nyob rau tib txoj kev raws li lub zog centrifugal ntawm cov dej ntws. Cov dej uas tau nkag mus rau hauv

foob thaum cov menyuam rotates yuav ntws mus rau sab saum toj ntawm lub labyrinth raws lub sealing nto nyob rau hauv cov nyhuv ntawm centrifugal quab yuam. Txhawm rau txhim kho cov nyhuv, sab saum toj ntawm lub nplhaib sealing sab hauv tuaj yeem txiav txim siab xaiv lub voj voog arc qauv.

(2) Ntxiv lub nplhaib sib khi rau sab nraud ntawm lub labyrinth foob los tsim lub foob foob, uas tuaj yeem tsis tsuas yog cuam tshuam nrog "qhov teeb meem ua pa" ntawm lub labyrinth foob, tab sis kuj yuav tsis ntxiv qhov tob ntawm lub rooj zaum zoo li lwm cov qauv foob. Sealing nplhaib NBR / PA6 khoom, lub teeb yuag, corrosion kuj, kev sib txhuam coefficient yog me dua li lwm yam yas yas.

(3) ntxiv lub nplhaib convex ntawm lub nplhaib sab hauv (saib daim duab 1), hloov cov kev taw qhia ntawm axial txav thaum plua plav lossis dej nkag mus rau qhov sib txawv ntawm lub nplhaib sab hauv. Thaum cov menyuam ua haujlwm ntawm kev kub ceev, lub tshuab nqus tsev yuav raug tsim los ntawm lub nplhaib convex thiab lub nplhaib sab nraud kom ntseeg tau tias cov nyhuv sealing.

2.Cov yam ntxwv ntawm tus txheej txheem thiab cov khoom xaiv

Lub radial khiav tawm ntawm cov menyuam feem ntau yog nyob ntawm qhov ua yuam kev radial ntawm lub tog raj kheej, qhov zoo ntawm lub rooj zaum bearing thiab coaxiality ntawm cov txheej txheem sib dhos. Tus nqi radial khiav tawm ntawm cov menyuam muaj kev cuam tshuam zoo rau kev ua haujlwm du ntawm cov khoom siv, tshwj xeeb tshaj yog thaum tus nqi radial khiav tawm loj dhau ntawm kev kub ceev, txoj siv conveyor yuav oscillate hnyav thiab cuam tshuam rau kev ua haujlwm ib txwm muaj.

Tam sim no, feem ntau ntawm cov chais ntawm cov chais yog hloov los ntawm cov kav hlau steel, uas yog hnyav hnyav. Qhov zoo ntawm cov kav dej, ovality thiab sab nraud txoj kab uas hla tolerances tsis yog ib qho yooj yim los lav, tshwj xeeb tshaj yog lub hav zoov ntawm lub discontinuity ntawm lub chim qauv cuam tshuam rau lub coaxiality, thiab nws yog ib qho yooj yim ua rau lub rollers yuav eccentric. Lub sijhawm vibration yuav tshwm sim vim yog lub zog centrifugal thaum lub sijhawm ua haujlwm, uas yuav cuam tshuam rau kev ua haujlwm du ntawm txoj siv conveyor.

3. Cov menyuam bearing xaiv

Lub neej ua haujlwm ntawm cov menyuam feem ntau yog nyob ntawm cov kabmob thiab cov foob. Ntau tus neeg nyob hauv khw siv cov kabmob loj-clearance. Piv nrog rau cov bearings zoo tib yam, loj-clearance bearings muaj ntau clearance thiab pob diameters, uas yuav txo tau lub rhiab heev rau coaxiality thiab txhim khu lub peev xwm hloov mus rau txawv teb chaws cov khoom.

Txawm li cas los xij, kev xaiv cov bearings nrog kev tshem tawm loj yuav cuam tshuam rau lub peev xwm ntawm axial bearing ntawm lub idler, tshwj xeeb tshaj yog tom qab txoj siv ceev tau nce, kev txav ntawm lub peev xwm ntawm axial bearing yuav ua rau lub xeev tsis sib xws ntawm txoj siv conveyor. Txawm tias nyob rau lub sijhawm hnyav, nws yog qhov yuav tsum tau nres lub tshuab rau kev debugging thiab overhauling txij thaum pib.

Hauv daim ntawv no, peb npaj yuav xaiv qhov sib sib zog nqus groove pob bearings nrog plua plav npog, uas tuaj yeem tsis tsuas yog ua kom huv ntawm sab hauv ntawm cov kabmob, txhim khu lub peev xwm axial, txo qhov kev puas tsuaj rau cov kabmob uas tshwm sim los ntawm axial high-frequency cuam tshuam quab yuam, tab sis kuj xyuas kom meej lub luag haujlwm ntawm cov kabmob txuas ntxiv lub neej ua haujlwm ntawm cov kabmob.

Daim ntawv no tau ua qee yam kev tshawb fawb txog kev kub ceev cov menyuam los ntawm cov qauv, kev sib khi, kev siv thiab kev siv tshuab ntawm cov ntaub ntawv tshiab. Cov menyuam siv cov qauv sib txuas sib txuas uas sib txuas nrog lub axial labyrinth thiab kov labyrinth, thiab siv lub pob sib sib zog nqus sib sib zog nqus nrog cov plua plav npog. Daim ntawv thov ntawm cov ntaub ntawv tshiab thiab kev hloov ntawm kev ua cov cuab yeej ua kom cov menyuam cov kev sib hloov tsis kam, radial ncig dhia thiab tsis muaj dej, plua plav-pov thawj sealing thiab lwm yam haujlwm. Raws li txoj kev loj hlob ntawm high-power, ntev-ntev thiab loj-throughput conveyors, Roller qauv npaj nyob rau hauv daim ntawv no muaj me ntsis rotating tsis kam, tsis tshua muaj suab nrov thiab ntev kev khiav hauj lwm lub neej, uas plays lub luag hauj lwm tseem ceeb nyob rau hauv lub tso zis hwj chim ntawm lub ceev conveyor.

Ntiaj teb no Conveyor Supplies Company Limited -RS series rollers

Ncej:Cov menyuam ncej yog ua los ntawm high precision txias rub puag ncig steel, uas tsis tau tempered thiab tempered. Precision chamfering milling tshuab, clamping nplhaib grooving tshuab yog siv los ua cov ncej, thiaj li xyuas kom meej tias cov axial txav ntawm cov menyuam yuav luag xoom.

Tube:Cov menyuam ncej yog ua los ntawm high precision txias rub puag ncig steel, uas tsis tau tempered thiab tempered. Roller plhaub txais tshwj xeeb zaus vuam yeeb nkab, me me dabtsi yog khoov degree, me elasticity. Txais yuav siab heev steel yeeb nkab chamfering txiav thiab puab lub qhov tshuab cuab yeej, precision machining ntawm ob kawg ntawm steel yeeb nkab, zoo xyuas kom meej lub concentrically ntawm cov menyuam, txo cov machining yuam kev.

Cov kabmob:Cov menyuam bearing txais tshwj xeeb C3 sib sib zog nqus groove pob bearing. Ua ntej sib sau ua ke, cov menyuam bearing tau ntim nrog lithium roj thiab kaw ruaj khov rau ob sab, uas tuaj yeem paub txog kev tu lub neej dawb thiab ua kom lub neej ntev ntawm cov kabmob.

Foob sib dhos:Cov menyuam foob tivthaiv yog ua los ntawm cov khoom siv nylon, thiab daim ntawv qauv yog hu rau labyrinth foob qauv. Sab hauv thiab sab nraud sealing tsim ib lub high-precision labyrinth channel, cov channel ntim nrog cov roj lithium mus sij hawm ntev, kom cov menyuam muaj cov dej tsis zoo thiab cov plua plav pov thawj. Precision chamfering milling tshuab, clamping nplhaib grooving tshuab yog siv los ua cov ncej, thiaj li xyuas kom meej tias cov axial txav ntawm cov menyuam yuav luag xoom.

Bearing Housing:Kev tsim cov kabmob vaj tse txais ntau theem meej tsis siv neeg stamping molding los xyuas kom meej qhov siab precision ntawm bearing thiab sealing txoj hauj lwm. Cov menyuam tub thiab cov kabmob vaj tsev nyob ntawm ob qhov kawg 3 hli tag nrho cov fllets yog welded los ntawm carbon dioxide gas tiv thaiv ib txhij nrog ib tug dual phom tsis siv neeg vuam tshuab muab ib tug yam tsawg kawg nkaus ntawm 70% nkag mus thiab xyuas kom meej idling tseem robust txawm nyob rau hauv siab loads thiab high speeds.

1. RS series rollers yog GCS high-endconveying rollers.

2. Cov khoom xa rov qab / nqa / cov menyuam trough muaj qhov kev tsim kho siab uas muaj txog li cuaj qhov sib khi, ua kom cov dej zoo thiab plua plav. Nrog roj hmab los yog steel seals, multi-groove labyrinth seals.

3. Cov kabmob vaj tse thiab cov menyuam tub raj yog welded los xyuas kom meej kev sib cuag zoo thoob plaws hauv cov menyuam. Roj yog lub roj nplua nyeem tas mus li.

4. Raws li cov neeg siv khoom xav tau, qhov saum npoo ntawm cov menyuam tuaj yeem pleev xim rau txhua yam xim.

5. Khoom siv: Feem ntau Q235 carbon steel (mob siab rau conveying cov menyuam), A3 txias duab ncej (tuaj yeem ua tau siab dua raws li cov neeg siv khoom sib txawv).

6. Txhua tus menyuam yuav dhau los ntawm kev tshuaj xyuas nruj thiab kev sim kom ntseeg tau tias txhua pawg ntawm cov menyuam yog qhov zoo tiag tiag.

Thov koj xav tiv tauj peb kom tau txais conveyor rollers.

Peb yog cov kws tshaj lij, zoo heev technology thiab kev pabcuam. Peb paub yuav ua li cas kom peb conveyor yob txav koj lub lag luam! Tshawb xyuas ntxivwww.gcsconveyor.com Emailgcs@gcsconveyoer.com

Cov xwm txheej zoo