High definition Power Roller Conveyor Systems - Conveyor Pulleys for Lagging – Vulcanized in Belt Conveyor – GCS

High definition Power Roller Conveyor Systems - Conveyor Pulleys for Lagging – Vulcanized in Belt Conveyor – GCS Detail:

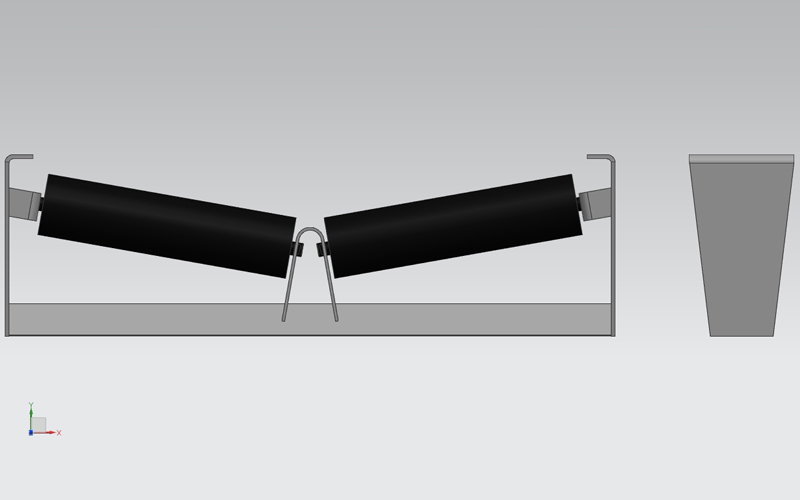

The drive pulley is the component that transmits power to the conveyor. The Pulley surface has smooth, lagged, and cast rubber, etc., and the rubber surface can be divided into rubber covered with herringbone and diamond. The herringbone rubber-cover surface has a large friction coefficient, good slip resistance, and drainage, but is directional. Diamond rubber-cover surface is used for conveyors that run in both directions. From the material, there are steel plate rolling, cast steel, and iron. From the structure, there is assembly plate, spoke and integral plate types.

The bend pulley is mainly under the belt. If the belt conveying direction is left, the bending roller is on the right side of the belt conveyor. The main structure is the bearing and the steel cylinder. The drive pulley is the drive wheel of the belt conveyor. From the relationship between the bend and drive pulley, it is like two wheels of the bicycle, the rear wheel is the drive pulley, and the front wheel is the bend pulley. There is no difference in the structure between the bend and drive pulley. They are composed of the main shaft roller bearing and the bearing chamber.

GCS(conveyor idler manufacturers) pulley quality inspection mainly checks the shaft quenching and high temperature tempering, weld line ultrasonic flaw detection, rubber material and hardness, dynamic balance test, etc. to ensure product working life.

Different kinds of conveyor pulleys

Our (GCS)conveyor pulleys in all the following sub-categories:

Head pulleys

The head pulley is located at the discharge point of the conveyor. It usually drives the conveyor and often has a larger diameter than other pulleys. For better traction, the head pulley is usually lagged (with either rubber or ceramic lagging material).

Tail and wing pulleys

The tail pulley is located at the loading end of the belt. It comes with either a flat face or a slatted profile (wing pulley), which cleans the belt by allowing material to fall between the support members.

Snub pulleys

A snub pulley improves the traction of the drive pulley, by increasing its belt wrap angle.

Drive pulleys

Drive pulleys, which can also be the head pulley, are driven by a motor and power transmission unit to propel the belt and material to the discharge.

Bend pulleys

A bend pulley is used for changing the direction of the belt.

Take-up pulley

A take-up pulley is used to provide the belt with the proper amount of tension. Its position is adjustable.

|

Shell Dia (Φ) |

250/215/400/500/630/800/1000/1250/1400/1600/1800(Customized) |

|

Length(mm) |

500-2800(Customized) |

Related product

Conveyor Drum Pulley For Heavy-Duty Conveyor

Drive Conveyor Pulleys For Conveyor Head Pulley

Rubber Lagged Drum Pulley by GCS

Product detail pictures:

Related Product Guide:

We attempt for excellence, support the customers", hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for High definition Power Roller Conveyor Systems - Conveyor Pulleys for Lagging – Vulcanized in Belt Conveyor – GCS , The product will supply to all over the world, such as: Belize, Nigeria, Paris, It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant" business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we will be happy to serve you.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.