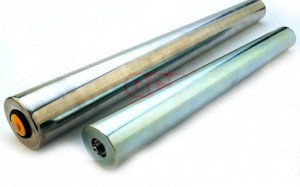

Gravity rollers with Spring Loaded Sprocket | GCS

(GCS)Gravity Conveyor Rollers allow free moving, efficient and safe transportation of goods at any operational stage of a conveyor line. Producing movement via natural forces, gravity conveyors are an economical material handling solution used in many industries for simplicity and functionality. Spring-loaded shafts not only provide hassle-free maintenance and simple installation they also ensure secure attachment to the conveyor frame (channel) maximizing roller and bearing function and performance. Rollers are available in zinc plated steel, nylon, and stainless steel for wash-down applications. It is recommended that there be a minimum of three rollers under the goods to being transported at any one time. The size of the object being transported can help determine the roller pitch on your conveyor system applying the three roller rule. (GCS conveyor belt roller manufacturers)can custom manufacture gravity conveyor rollers to length, diameter, and shaft requirements.

Plastic Sleeve Sprocket Roller

| Model (Roller Dia) | (T) | Shaft Dia | Sprocket | Roller length | Tube Material | Surface Finishing |

| SLS50 | T=1.2, 1.5 | φ12 | 14 tooth x 1/2" pitch according to customers' requirement | 300-1500 | Carbon Steel Stain less Steel | Zinc plated Chrome plated |

| SLS60 | T=2.0 | φ12 15 | 300-1500 | |||

| SLS76 | T=2.0 3.0 | φ15φ20 | 300-1500 |

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.