Fast delivery Super Heavy Duty Roller Conveyor - Conveying Rollers Of Trough Rubber Idlers And Bracket | GCS – GCS

Fast delivery Super Heavy Duty Roller Conveyor - Conveying Rollers Of Trough Rubber Idlers And Bracket | GCS – GCS Detail:

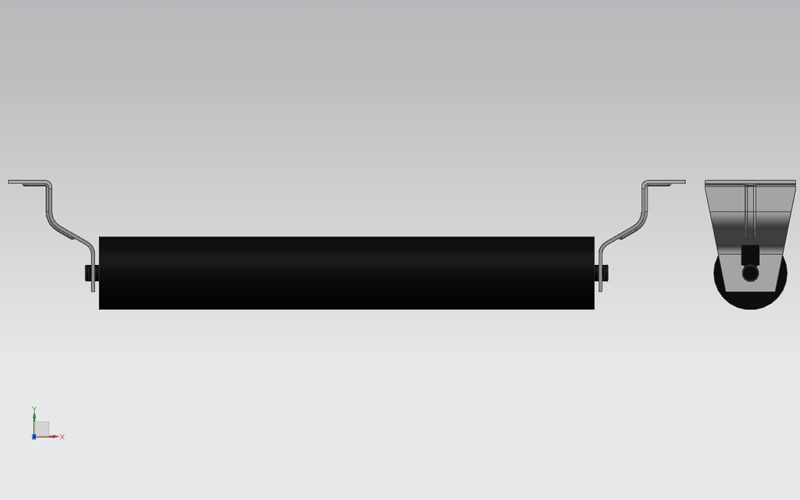

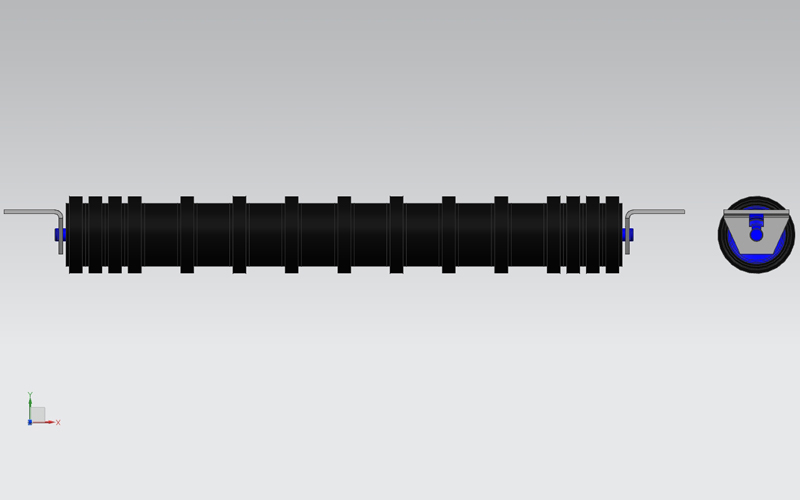

Conveying Rollers Of Trough Idlers And bracket For Heavy Roller For Sale|GCS

How Troughing Idlers Work

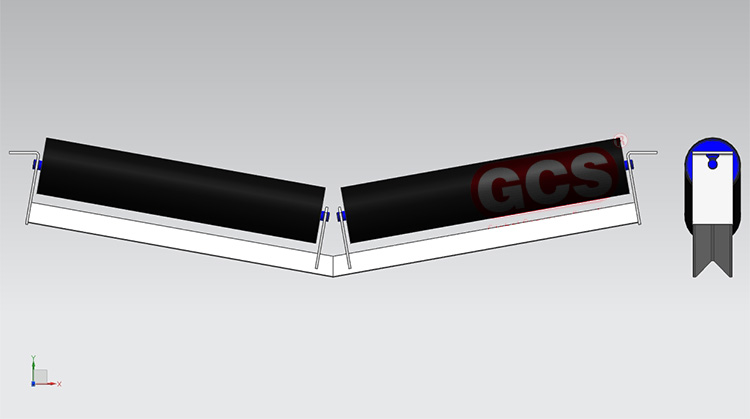

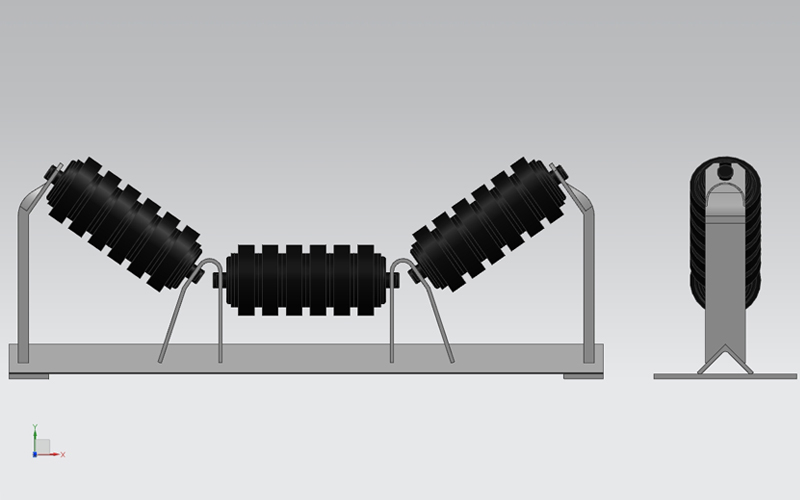

Troughing idlers consist of three or more idlers that guide the conveyor belt. They are found on the carrying-side of the belt and are installed along the entire length of the conveyor. The troughing idlers work to keep the belt in the same configuration all along its length, which thus maintains the same cross-sectional area as the belt carries mined materials from their source to the drop off point. A troughing idler is comprised of a central idler roll, which has a fixed width, and two or more wing idlers located on each side of the central idler roll. The wing idlers can be adjusted up or down to change the toughing angle, which affects the depth of the trough created by the conveyor belt as it moves.

Benefits of Troughing Idlers

Troughing idlers offer two important benefits. First, the troughing idlers keep the belt’s shape consistent throughout its journey, which improves both stability and carrying capacity. Second, troughing idlers reduce the amount of material that may accidentally spill over the edge of the conveyor system, which improves productivity and also increases the safety of workers, who may be at risk from falling material while working near conveying equipment.

Trough Idler -SERIES RS/HRS

3 ROLL TROUGH IDLERS-178 DIAMETER

| Code No. | A | B | 20° | 30° | 35° | 45° | Base Angle Size | Shaft Dia. | Trough Mass R.P. | Total Mass | Shaft Dia. | Impact Mass R.P. | Total Mass | ||||

| C | D | C | D | C | D | C | D | ||||||||||

| XX-A1-3-D3A2-1200-YY | 442 | 1450 | 157 | 1326 | 229 | 1263 | 265 | 1200 | 315 | 1068 | 90 | 38 | 42.0 | 78.1 | 38 | 38.7 | 83.7 |

| XX-A1-3-E3A3-1350-YY | 494 | 1650 | 177 | 1472 | 259 | 1395 | 293 | 1336 | 350 | 1196 | 100 | 38 | 46.0 | 91.7 | 38 | 42.7 | 98.7 |

| XX-A1-3-E3A3-1400-YY | 500 | 1700 | 177 | 1492 | 259 | 1419 | 293 | 1358 | 350 | 1214 | 100 | 38 | 46.4 | 92.9 | 38 | 43.3 | 100.5 |

| XX-A1-3-E3A3-1500-YY | 547 | 1800 | 191 | 1628 | 289 | 1541 | 318 | 1486 | 383 | 1332 | 100 | 38 | 50.0 | 99.3 | 38 | 47.3 | 107.4 |

| XX-A1-3-F3A5-1600-YY | 567 | 2000 | 191 | 1688 | 289 | 1603 | 338 | 1526 | 405 | 1368 | 125 | 38 | 51.5 | 111.0 | 38 | 48.7 | 122.3 |

| XX-A1-3-F3A5-1800-YY | 631 | 2200 | 226 | 1888 | 328 | 1773 | 373 | 1700 | 439 | 1544 | 125 | 38 | 56.4 | 121.1 | 38 | 54.3 | 133.8 |

| XX-A1-3-G3A5-2000-YY | 706 | 2400 | 247 | 2082 | 364 | 1975 | 409 | 1904 | 488 | 1730 | 140 | 38 | 62.2 | 148.3 | 42 | 60.5 | 167.1 |

| XX-A1-3-G3A5-2200-YY | 785 | 2600 | 276 | 2310 | 405 | 2193 | 463 | 2098 | 552 | 1918 | 140 | 42 | 68.2 | 165.3 | 42 | 67.1 | 186.0 |

Note:XX-inputfor: RS or HRS.

YY-Inputforangle: 20° , 30° , 35° ,45°

Base angle size nominated is normal stock standard. Dimensions E and F vary with change in base angle size as tabulated below.

Code numbers shown are for plain trough idlers, for impact idlers change both” A’sH in code numbers to ” B’s

SERIES RS/HRS 3 ROLL TROUGH IDLERS-178 DIAMETER

| Code No. | A | B | 20° | 30° | 35° | 45° | Base Angle Size | Shaft Dia. | Trough Mass R.P. | Total Mass | Shaft Dia. | Impact Mass R.P. | Total Mass | ||||

| C | D | C | D | C | D | C | D | ||||||||||

| XX-A1-3-F3A5-1600-YY | 363 | 1250 | 127 | 1092 | 188 | 1038 | 215 | 988 | 256 | 882 | 75 | 27 | 21.1 | 42.2 | 38 | 27.2 | 57.9 |

| XX-A1-3-F3A5-1800-YY | 388 | 1300 | 142 | 1162 | 204 | 1104 | 226 | 1058 | 270 | 946 | 75 | 27 | 22.2 | 44.1 | 38 | 28.5 | 60.6 |

| XX-A1-3-G3A5-2000-YY | 441 | 1450 | 157 | 1314 | 224 | 1252 | 260 | 1192 | 311 | 1068 | 90 | 27 | 24.5 | 50.5 | 38 | 32.4 | 70.4 |

| XX-A1-3-G3A5-2200-YY | 493 | 1650 | 177 | 1462 | 255 | 1392 | 283 | 1338 | 346 | 1196 | 90 | 30 | 26.8 | 56.6 | 38 | 35.2 | 76.8 |

| XX-A1-3-G3A5-2400-YY | 499 | 1700 | 177 | 1484 | 255 | 1414 | 295 | 1342 | 346 | 1224 | 90 | 30 | 27.0 | 57.6 | 38 | 35.7 | 78.0 |

| XX-A1-3-G3A5-2500-YY | 546 | 1800 | 192 | 1618 | 287 | 1530 | 316 | 1474 | 389 | 1312 | 100 | 30 | 29.1 | 68.1 | 38 | 39.1 | 92.2 |

| XX-A1-3-G3A5-2600-YY | 566 | 2000 | 192 | 1680 | 287 | 1592 | 334 | 1518 | 389 | 1390 | 125 | 33 | 30.0 | 80.5 | 38 | 39.9 | 105.7 |

| XX-A1-3-G3A5-2800-YY | 630 | 2200 | 222 | 1856 | 323 | 1760 | 369 | 1688 | 436 | 1544 | 125 | 33 | 32.8 | 88.0 | 38 | 44.8 | 117.1 |

| XX-A1-3-G3A5-3000-YY | |||||||||||||||||

Note: XX-inputfor: RS or HRS. 表格参数不对 修改

YY-Input for angle: 20°, 30°,35°,45°

Base angle size nominated is normal stock standard. Dimensions E and F do not vary with change in base angle size as tabulated below.

Code numbers shown are for plain trough idlers, for impact idlers change both” A’sn in code numbers to ” B*s

| Base Angle | E | F |

| 75x75x6 | 165 | 260 |

| 90 x 90 x 7 | 180 | 270 |

| 100x 100×8 | 200 | 280 |

| 127x 127×8 | 240 | 300 |

| 140x140x 12 | 280 | 320 |

Related product

Roller For DIA(mm) 102|114|117 Flat Return Idlers

Steel Garland Rollers 2roll by GCS

Conveyor System Cone self-aligning roller

GCS conveyor roller chain manufacturers reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

Tell Us Your Requirement About Trough Idler .Contact us Now!

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm to the long-term to develop together with consumers for mutual reciprocity and mutual advantage for Fast delivery Super Heavy Duty Roller Conveyor - Conveying Rollers Of Trough Rubber Idlers And Bracket | GCS – GCS , The product will supply to all over the world, such as: Panama, Hungary, Romania, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!