Factory wholesale Heavy Duty Roller Conveyors - WEIGHT OMETER STEEL IDLER | GCS – GCS

Factory wholesale Heavy Duty Roller Conveyors - WEIGHT OMETER STEEL IDLER | GCS – GCS Detail:

Weighmeters are used to count the quantity and weight of materials for specific handling requirements.

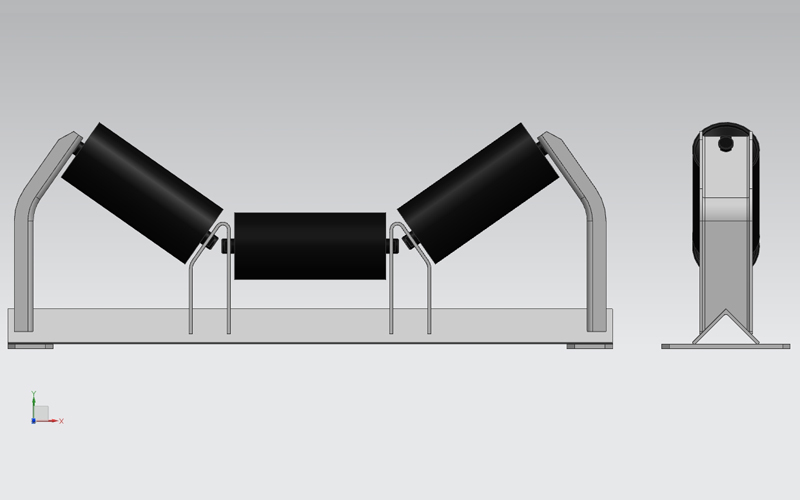

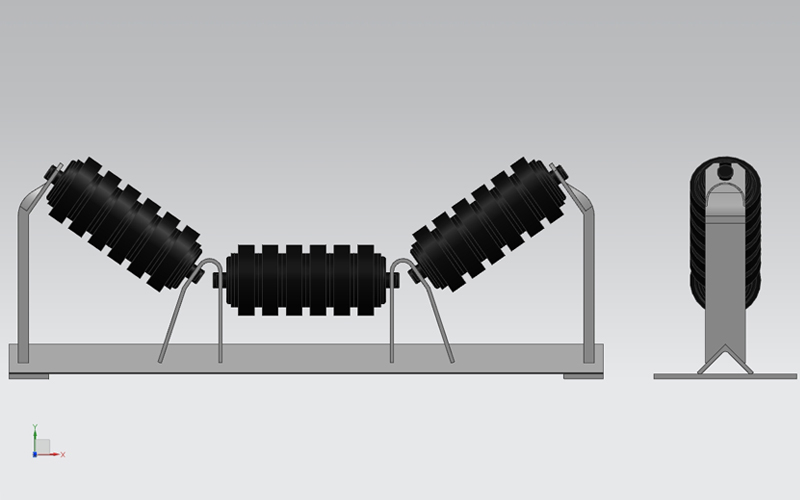

The difference is that the weighting rollers have inline idlers with counterbalance rollers to reduce vibration and improve accuracy. A top screw is also added to assist with field leveling. Leveling ensures that the product is in a stable condition when passing through the belt scale, thus ensuring optimal accuracy of the belt scale.

GCS conveyor supplies company can customize the production of multiple specifications weightometer should be used in the conveyor rollers.

The conveyor idler is widely used in mining and other docks former dock transportation places with high dust and corrosive environment.

Get quality conveyor rollers, custom conveyor rollers, matching roller brackets, and more of what you need.

GCS-Weigh Quality Roller Idlers |GCS

WEIGHT ODOMETER STEEL IDLER conveyor idlers are a vital part of the conveyor weigh scales to ensure maximum accuracy and minimum vibration when measuring.

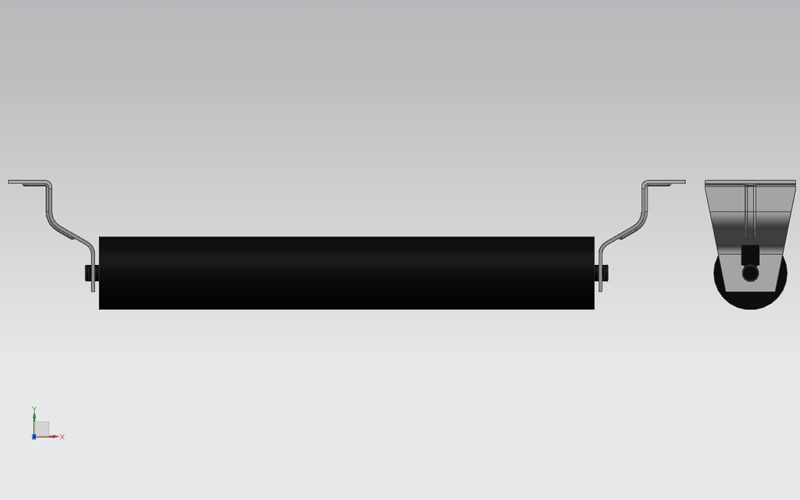

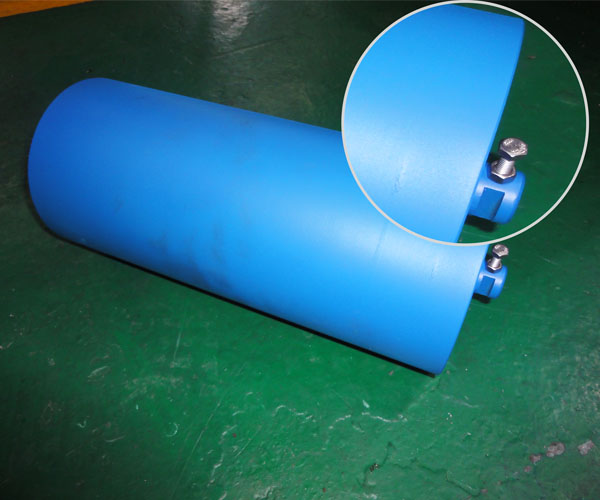

The Weigh roller’s precision bored and chamfered tubes are designed to achieve correct housing squareness and all shaft ends are fitted with leveling screws to provide vertical adjustments. In summary, it is a maintenance-free, accurate measuring roller.

BENEFITS:

Machined and balanced to ensure superior belt weigh measurability to the conveyor belt accessories

Manufactured and processed in-house to ensure the highest quality

Fitted with leveling screws at each end to provide vertical adjustment

Low TIR and MIS values to reduce inaccurate measurements

Wide range of size offerings (diameter and bearings)

Performance of the highest quality

General specification suitability.

Belt width options: 350-2500mm / Roller diameter sizes: 102-194mmFunction: In dynamic weighing applications it is vital to ensure that the material passes through the belt scale or feeder with minimal vibration and movement, thus reducing errors and improving accuracy. If incorrectly specified, rotating rollers can have a significant impact on accuracy. As part of the overall system, the weighing rollers are fitted with inline idler frames to ensure optimum accuracy is obtained. Service and alignment

In addition to the use of weighing rollers and inline idler frames, all dynamic weighing applications require regular alignment, system checks, and calibration to maintain accuracy.

GCS-Flexible Roller Conveyors video

GCS-Roller Type

Related product

Aluminum Conveyor Roller Idler

Rubber Disc Vee Return Idler by GCS Suppliers

Trough impact roller is applied in the mine

GCS conveyor belt system manufacturers reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

Tell Us Your Requirement About conveyor rollers.Contact us Now!

Product detail pictures:

Related Product Guide:

We attempt for excellence, support the customers", hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for Factory wholesale Heavy Duty Roller Conveyors - WEIGHT OMETER STEEL IDLER | GCS – GCS , The product will supply to all over the world, such as: United States, Irish, Congo, With a fully integrated operation system, our company has won a good fame for our high quality products, reasonable prices and good services. Meanwhile, we have established a strict quality management system conducted in material incoming, processing and delivery. Abiding by the principle of "Credit first and customer supremacy", we sincerely welcome clients from home and abroad to cooperate with us and advance together to create a brilliant future.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.