Conveyor Idler

Conveyor Idler |Pulley|Conveyor systems

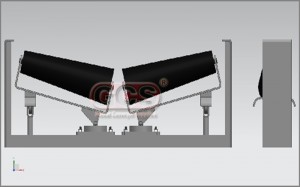

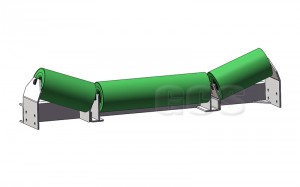

Conveyor idlers play a vital role in supporting and guiding the conveyor belt, ensuring stable and efficient material handling. Among the most widely used are troughing idlers, which hold the carrying side of the belt at angles of 20°, 35°, or 45° to keep bulk materials centered and reduce spillage. On the return side, flat and V-return idlers stabilize the empty belt, minimizing sagging and extending belt service life.

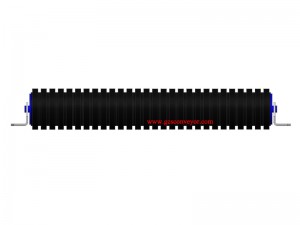

For areas with heavy impact and sticky materials, specialized designs provide added protection and cleaning. Impact idlers, fitted with rubber rings or discs, absorb shock at loading points to safeguard both the belt and structure. Meanwhile, rubber disc and self-cleaning idlers continuously knock off residues and prevent material build-up, keeping conveyors running smoothly and reducing downtime.

Together, these idler solutions form a complete system that supports the belt under all conditions—from heavy-duty loading zones to return runs. Combined with our advanced sealing technology, premium bearings, and corrosion-resistant materials, our rollers deliver longer service life, lower maintenance, and reliable performance even in the harshest industrial environments.

Premium Materials & Specifications

◆ Shafts – Manufactured from cold-drawn ST37 steel (DIN 17100, E24 AFNOR NFA 35501) for strength and precision.

◆ Rods – Precision-ground to ISO h6 standards (20, 25, 30, 40 mm), ensuring perfect fit in bearing and seal assemblies.

◆ Steel Tubes – Welded to DIN 2394, using robust ST37 steel for durability under heavy loads.

◆ Bearing Seats – Cold stamped to ISO M7 accuracy from deep-stamped steel (DIN 1623–1624) for secure bearing alignment.

◆ Bearings – High-performance deep groove ball bearings (DIN 62/63 series, clearance class C3) for smooth rotation.

◆ Inner Sealing Ring – Made of NYLON6 (ISO Pa6), providing excellent resistance to dust and moisture.

◆ Labyrinth Seal – Triple-groove design in NYLON6, effectively preventing contaminants from entering.

◆ Outer Sealing Ring – V-shaped rubber seal, wear-resistant, low-friction, and oxidation-resistant for extended service life.

◆ Protective Cover – Corrosion-resistant zinc-magnesium aluminium-copper alloy, protecting rollers against axial oscillation and vibration.

◆ Lubrication – Premium grade 2 and 3 lithium-based grease ensures continuous, long-term bearing lubrication.

If you would like to learn more, GCS is always available to help you here!