Conveyor Guide idler roller adjustment of conveyor belts

Guide rollers help to protect the most expensive part of the conveyor - the belt. They prevent the belt from slipping off the rollers and prevent damage to the conveyor structure or other objects. Guide rollers adjust the conveyor belts to limit possible side-slip of the belt and keep it aligned. These rollers can be mounted vertically to control direction, as belt guides, or as horizontal cantilevers for specific conveyor systems. Usually with a tube diameter of 30mm - 76mm .GCS belt conveyor idler roller manufacture also meets your customized requirements.

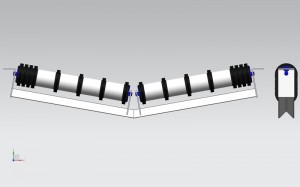

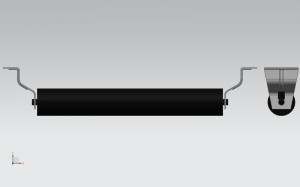

Conveyor guide roller drawing

Conveyor guide roller specifications

|

SPECIFICATIONS

|

|||

|

Diameter

|

φ50,φ60, φ76, φ89

|

||

|

Length

|

customized

|

||

|

Tube

|

Q235(GB), Q345(GB), welded with DIN2394 standard

|

||

|

Shaft

|

A3 and 45# steel(GB)

|

||

|

Bearing

|

Single & Double Row Deep Groove Ball Bearing 2RS&ZZ with C3 clearance

|

||

|

Bearing Housing/Seat

|

Cold press working fit ISO M7 accuracy

Deep Press steel with raw material fit DIN 1623-1624 standard

|

||

|

Lubricating Oil

|

Grade 2 or 3 long-lasting lithium grease

|

||

|

Welding

|

Mixed gas shielded arc welding end

|

||

|

Painting

|

Ordinary painting, hot galvanized painting, electric static spraying painting, baked pai |

||

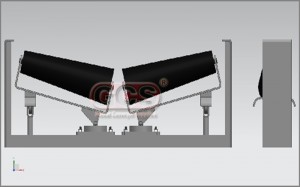

Conveyor guide rollers applications

Successful Cases

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.