Carrying conveyor idler rollers – China Conveyor Idler Manufacturers

Material:

Carrier rollers are usually made of high-quality steel, such as carbon steel or stainless steel, to ensure that they can withstand heavy loads and long-term wear and tear.

Application:

Carrier rollers are used in industries such as mining, construction, and manufacturing where heavy loads need to be transported over long distances.

Structure:

The structure of a carrier roller usually consists of a cylindrical roller body, a shaft, and bearings. The roller body is the main component that carries the weight of the load and the shaft connects the roller body to the conveyor frame. The bearing ensures the smooth rotation of the roller body. Bearing Type: Commonly used load-bearing roller bearings are deep groove ball bearings, spherical roller bearings, tapered roller bearings, and so on. The type of bearing used depends on the load capacity of the conveyor system, operating speed, and environmental conditions.

Types:

There are different types of carrier rollers available, such as grooved rollers, impact rollers, return rollers, and training rollers. Each type is designed for a specific conveyor application.

Transport packages:

Load carrying rollers are usually packed in wooden or cardboard boxes to protect them during transport

Samples:

Samples of Load Carrier Rollers are available on request to help customers assess the quality of the product and its suitability for their application.

Customisation:

Carrier rollers can be customised to meet the specific requirements of the conveyor system, such as roller diameter, length, shaft size, bearing type and seal type Customisation Requirements

GCS conveyor roller Series

Model: RS62 63 SERIES

| BEARING | PIPE Dia |

| 6204/6205 | 60/76/89/108/114/127/133 |

| 6305/6306/6307/6308/63096310/6311/6312 | 76/89/108/114/127/133/159/165/194/219 |

RS roller is premium product with triple anti-dust structure which can effectively prevent water and dust. This model applies to the conveyor belt systems that can carry large volume and high speed dusty bulks.

Features

Belt conveyor idler Trough roller trough idler conveyor roller RS waterproof and dust proof heavy-duty conveyor roller/idler:

1. These RS series rollers belong to GCS high-end conveyor roller.

2. This return/carrier/trough roller has a high precision structure, composing as many as nine seal parts which ensures the roller's good capability of water and dust resistance. With rubber or steel seals, and multi-labyrinth seals.

3. The bearing housing and tube are fully welded to ensure good contact with the whole roller. Grease is a permanent lubricant.

4. Roller surface could be painted any color as per customer request.

5. Material: normally Q235 tube (especially for conveyor roller), A3 cold-drawn shaft (Could be of very high precision to meet different customer requirements.)

6. Each roller would be through strict inspection and testing to ensure every outcoming roller is of truly high quality.

Welcome to contact us at any time for conveyor roller/idler. We are professional and excellent in technology and service.

We know how to make our conveyor roller move your business!

Product Description

Carrying roller are used to support the conveyor belt and are installed on the groove-shape frame, groove-shape forward inclined idler frames and transition idler frames. A full range of steel rollers are available of idler rollers.

|

SPECIFICATIONS |

|

| Diameter | φ89, φ102, φ108, φ114, φ127, φ133, φ139, φ152, φ159, φ165, φ194 |

| Length | 145mm-2800mm |

| Tube | Q235(GB), Q345(GB), welded with DIN2394 standed |

| Shaft | A3 and 45# steel(GB) |

| Bearing | Single & Double Row Deep Groove Ball Bearing 2RS&ZZ with C3 clearance |

| Bearing Housing/Seat | Cold press working fit ISO M7 accuracyDeep Press steel with raw material fit DIN 1623-1624 standard |

| Lubricating Oil | Grade 2 or 3 long-lasting lithium greasae |

| Welding | Mixed gas shielded arc welding end |

| Painting | Ordinary painting, hot galvanized painting, electric static spraying painting, baked painting |

| Diameter of Tube | Length of Tube | Bearing Type | |

| mm | inch |

mm |

|

| 63.5 | 2 1/2 | 150-3500 | 6204 |

| 76 | 3 | 150-3500 | 6204 6205 |

| 89 | 3 1/2 | 150-3500 | 6204 6205 |

| 102 | 4 | 150-3500 | 6204 6205 6305 |

| 108 | 4 1/4 | 150-3500 | 6204 6205 6305 6306 |

| 114 | 4 1/2 | 150-3500 | 6204 6205 6305 6306 |

| 127 | 5 | 150-3500 | 6204 6205 6305 6306 |

| 133 | 5 1/4 | 150-3500 | 6205 6206 6207 6305 6306 |

| 140 | 5 1/2 | 150-3500 | 6205 6206 6207 6305 6306 |

| 152 | 6 | 150-3500 | 6205 6206 6207 6305 6306 6307 6308 |

| 159 | 6 1/4 | 150-3500 | 6205 6206 6207 6305 6306 6307 6308 |

| 165 | 6 1/2 | 150-3500 | 6207 6305 6306 6307 6308 |

| 177.8 | 7 | 150-3500 | 6207 6306 6307 6308 6309 |

| 190.5 | 7 1/2 | 150-3500 | 6207 6306 6307 6308 6309 |

| 194 | 7 5/8 | 150-3500 | 6207 6307 6308 6309 6310 |

| 219 | 8 5/8 | 150-3500 | 6308 6309 6310 |

Type Of Carrier Rollers

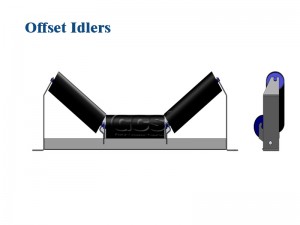

Steel Trough Set (Offset)

Type of carrying roller-

Offset Trough Frame set for medium to heavy conveyor load operations where trough belt shape is required

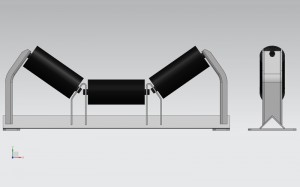

Steel Trough Set (Inline)

Type of carrying roller-

Inline Trough Frame set for medium to heavy conveyor load operations where trough belt shape is required

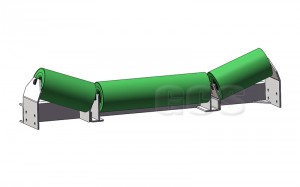

Transition Frame Steel Offset

Carrying roller-

Offset Steel Roller Transition Frame with fixed degree incremental belt angle adjustment.

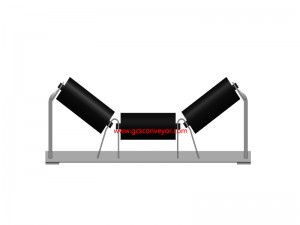

Steel Carry Idler + Brackets

Carrying roller-

Steel Carry Idler for general medium to heavy load, mid conveyor operation where trough belt angle is not required.

|

Basic Info |

|

| Model NO. | NS/RS/LS |

| Surface Finishing | Painting, Galvanized or as Your Demand |

| Length | 200-2800mm |

| Colour | as Your Requirement |

| Import Bearings | Lyc(China Famous)NSK, SKF |

| Standard | ISO, Cema, DIN |

| Certification | ISO9001:2015 |

| Ctructure | Conveyor Roller |

| Idler Diameter | 89,108,133,159,194,219mm |

| Color | as Per Your Request |

| Features | Durable ,Power Saving ,etc. |

| Material Feature | Durable |

| After-Sales Service | Engineers Available to Service Machinery Overseas |

| Load Capacity | as Per Order |

| Packaging Details | Wooden Case, Pallet Packaging, Standard Packaging |

| Trademark | GCS, GCS |

| Transport Package | Wooden Box |

| Specification | Customers′ Requirements |

| Origin | Guangdong, China (Mainland) |

| HS Code | 8431390000 |

Roller Idler Application

GCS Conveyor Roller products are widely used in thermal power generation, harbours, cement plants, metallurgy and as well as the light duty conveying devices for industries.

v roller conveyor

Mining Conveyor

Video

Belt Conveyor Roller Idler

Introduction conveyor roller in conveyor

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.