Belt Conveyor Rubber Disc for pipe rollers heavy duty | GCS

Manufacturer of Return Idler – V returm rubber disc idler , Return Idler offered by GCS’S

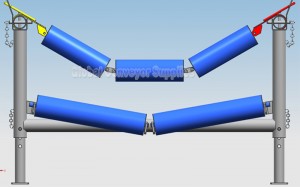

The purpose of using a flat return idler is to support the belt from the return side to prevent stretching, sagging and failure of the belt, which increases the service life of the conveyor belt.

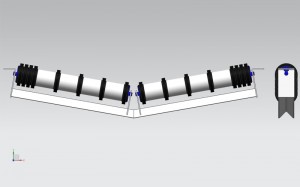

GCS'S vee return idler frames are engineered and fabricated to exceed industry standards and/or customer specifications. Manufacturing techniques include CNC laser cutters and robotic welding. The combination of high-tech manufacturing equipment, welding management/assurance systems ensures all vee return idler frames set a benchmark for tolerance and quality levels. GCS'S vee return idlers are designed for use on the return side of the belt with the vee profile assisting with belt tracking. They are available with a variety of frame and mounting configurations.

Bandwidth specifications (mm) 900-3000

Pipe diameter specifications (mm) 127 | 152 | 178

Rubber Return Idler - SERIES RS/HRS

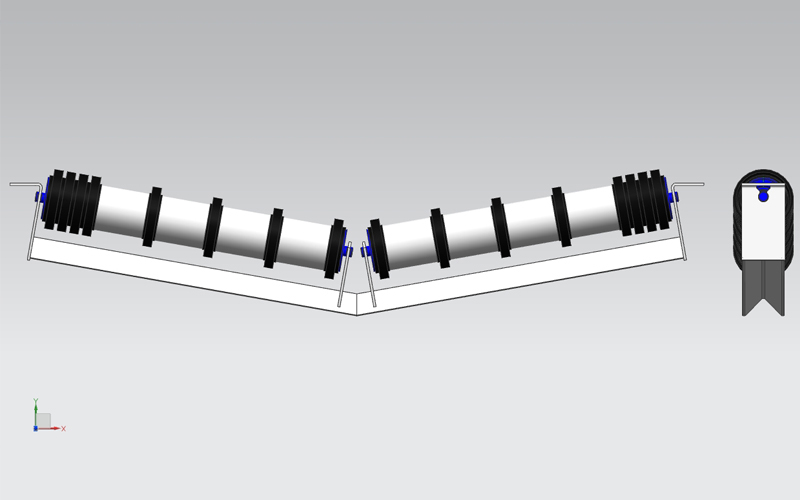

RUBBER DISC VEE RETURN IDLER-WITHOUT SPACER 127 DIAMETER

| Code No. | A | B | 5° | Qty. End Discs | Qty. Centre Discs | Base Angle Size | Shaft Dia. | Mass R.P. | Total Mass | ||

| C | D | F | |||||||||

| XX-G1-2-B0K2-0900-05 | 470 | 1150 | 44 | 1010 | 21 | 5 | 3 | 64 | 27 | 12.6 | 23.7 |

| XX-G1-2-B0K2-1000-05 | 520 | 1250 | 48 | 1110 | 25 | 5 | 3 | 64 | 27 | 13.4 | 25.5 |

| XX-G1-2-C0K2-1050-05 | 540 | 1300 | 50 | 1160 | 27 | 5 | 3 | 76 | 27 | 13.6 | 29.4 |

| XX-G1-2-C0K2-1200-05 | 630 | 1450 | 57 | 1310 | 34 | 5 | 4 | 76 | 27 | 15.7 | 33.3 |

| XX-G1-2-C0K3-1350-05 | 705 | 1650 | 64 | 1460 | 43 | 5 | 5 | 76 | 27 | 17.7 | 37.6 |

| XX-G1-2-C0K3-1400-05 | 730 | 1700 | 66 | 1510 | 45 | 5 | 5 | 76 | 27 | 17.9 | 38.7 |

| XX-G1-2-C0K3-1500-05 | 780 | 1800 | 70 | 1610 | 49 | 6 | 5 | 76 | 27 | 19.3 | 41.0 |

| XX-G1-2-C0K5-1600-05 | 830 | 2000 | 74 | 1710 | 57 | 6 | 6 | 76 | 27 | 20.8 | 44.8 |

| XX-G1-2-D0K5-1800-05 | 930 | 2200 | 85 | 1910 | 68 | 6 | 7 | 89 | 27 | 22.9 | 52.2 |

Note: XX-input for: RS or HRS.

Base angle size nominated is normal stock standard.

Dimension G will vary with change in base angle size.

| Base Angle | G |

| 63 x 63 x 5L | 214 |

| 75x75x6L | 224 |

| 90x90x9L | 234 |

| 100x100x8L | 244 |

| 125x125x8L | 264 |

• Discs retained with spring clips.

• Suitable only for use up to 5 degree troughing angle.

GCS reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.