100% Original Conveyor Rollers Heavy Duty - Trough impact roller is applied in the mine | GCS – GCS

100% Original Conveyor Rollers Heavy Duty - Trough impact roller is applied in the mine | GCS – GCS Detail:

Rubber Disc Conveyor Impact Roller Set

Troughing angle 10°,20°,30°,35°,45°

Tube Steel Q 235(GB), Q 345(GB), stainless steel (201,304), rubber, nylon, HDPE, UHMWPE

Roller Diameter 89-194 mm

Bearing Single & Double Row Deep Groove Ball Bearing 2RS & ZZ with C3 clearance, with brand SKF, NSK, HRB…

Bearing Housing/Seat Cold press working fit ISO M7 accuracy

Deep Press steel with raw material fit DIN 1623-1624 standard

Lubricating Oil Grade 2 or 3 long-lasting lithium greasae

Welding Mixed gas shielded arc welding end

Painting Powder coated,Spray paint,Galvanized,Rubber lagging.

Transfer points are critical operational areas for conveyor belts.

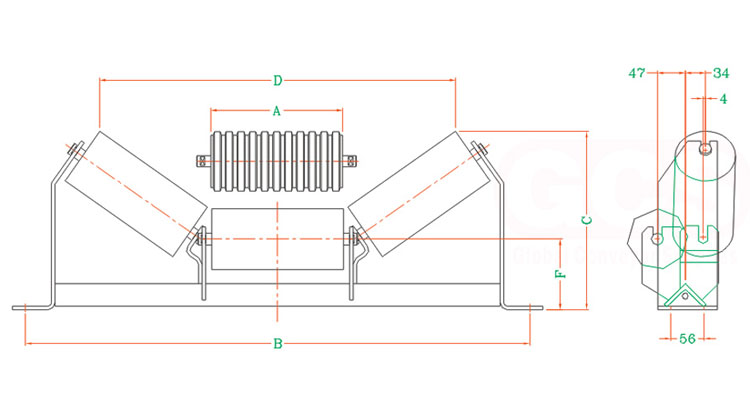

Trough Eccentric Idler – SERIES LS/RS

3 ROLL TROUGH IDLERS-OFFSET-114 DIAMETER

| Code No. | A | B | 20° | 30° | 35° | 45° | E | F | Base Angle Size | Shaft Dia. | Mass R.P. | Total Mass | Impact | |||||

| C | D | C | D | C | D | C | D | R.P. | Mass | |||||||||

| XX-A1-3-B1A2-0500-YY | 188 | 750 | 244 | 574 | 272 | 531 | 281 | 508 | 312 | 454 | 56 | 178 | 63 | 27 | 7.2 | 17.8 | 7.5 | 18.1 |

| XX-A1-3-B1A2-0600-YY | 223 | 850 | 257 | 678 | 289 | 626 | 304 | 597 | 336 | 538 | 56 | 178 | 63 | 27 | 8.1 | 19.8 | 8.6 | 20.3 |

| XX-A1-3-B1A2-0650-YY | 243 | 900 | 264 | 738 | 301 | 685 | 317 | 650 | 350 | 594 | 56 | 178 | 63 | 27 | 8.6 | 21.0 | 9.4 | 21.9 |

| XX-A1-3-B1A2-0750-YY | 277 | 1000 | 276 | 834 | 315 | 775 | 333 | 743 | 374 | 670 | 56 | 178 | 63 | 27 | 9.4 | 22.9 | 10.4 | 23.9 |

| XX-A1-3-B1A2-0800-YY | 293 | 1050 | 280 | 880 | 326 | 815 | 345 | 782 | 385 | 710 | 56 | 178 | 63 | 27 | 9.8 | 23.9 | 11.1 | 25.2 |

| XX-A1-3-C1A2-0900-YY | 330 | 1150 | 292 | 986 | 344 | 920 | 369 | 877 | 411 | 800 | 56 | 178 | 75 | 27 | 10.7 | 29.0 | 12.2 | 30.5 |

| XX-A1-3-C1A2-1000-YY | 357 | 1250 | 303 | 1064 | 355 | 996 | 379 | 956 | 432 | 866 | 56 | 178 | 75 | 27 | 11.4 | 31.0 | 13.1 | 32.7 |

| XX-A1-3-C1A2-1050-YY | 382 | 1300 | 313 | 1134 | 372 | 1060 | 397 | 1018 | 450 | 924 | 56 | 178 | 75 | 27 | 12.0 | 32.4 | 13.5 | 33.9 |

| XX-A1-3-C1A2-1200-YY | 435 | 1450 | 329 | 1292 | 395 | 1206 | 425 | 1159 | 487 | 1050 | 56 | 178 | 75 | 27 | 13.3 | 35.7 | 15.3 | 37.7 |

Note: XX-input for: LS or RS.

YY-Input for angle:20°, 30°, 35°,45°

Base angle size nominated is normal stock standard. Dimensions F does not vary with change in base angle size.

3 ROLL TROUGH IDLERS-OFFSET-127 DIAMETER

| Code No. | A | B | 20° | 30° | 35° | 45° | E | F | Base Angle Size | Shaft Dia. | Trough | Impact | ||||||

| Mass R.P. | Total Mass | Mass R.P. | Total Mass | |||||||||||||||

| C | D | C | D | C | D | C | D | |||||||||||

| XX-A1-3-B1A2-0500-YY | 189 | 750 | 250 | 571 | 277 | 525 | 286 | 501 | 317 | 445 | 56 | 184 | 63 | 27 | 8.3 | 18.9 | 8.9 | 21.0 |

| XX-A1-3-B1A2-0600-YY | 224 | 850 | 263 | 675 | 294 | 620 | 309 | 590 | 341 | 529 | 56 | 184 | 63 | 27 | 9.3 | 21.1 | 10.5 | 24.1 |

| XX-A1-3-B1A2-0650-YY | 244 | 900 | 270 | 735 | 306 | 679 | 322 | 643 | 355 | 585 | 56 | 184 | 63 | 27 | 9.9 | 22.4 | 11.4 | 25.8 |

| XX-A1-3-B1A2-0750-YY | 278 | 1000 | 282 | 831 | 320 | 769 | 338 | 738 | 379 | 661 | 56 | 184 | 63 | 27 | 10.9 | 24.4 | 12.9 | 28.6 |

| XX-A1-3-B1A2-0800-YY | 294 | 1050 | 286 | 877 | 331 | 809 | 350 | 777 | 390 | 701 | 56 | 184 | 63 | 27 | 11.4 | 25.5 | 13.6 | 30.1 |

| XX-A1-3-C1A2-0900-YY | 331 | 1150 | 298 | 983 | 349 | 914 | 374 | 870 | 416 | 791 | 56 | 184 | 75 | 27 | 12.5 | 30.8 | 15.3 | 37.4 |

| XX-A1-3-C1A2-1000-YY | 358 | 1250 | 309 | 1061 | 360 | 990 | 384 | 949 | 437 | 857 | 56 | 184 | 75 | 27 | 13.3 | 32.8 | 16.5 | 40.2 |

| XX-A1-3-C1A2-1050-YY | 383 | 1300 | 319 | 1131 | 377 | 1054 | 402 | 1011 | 455 | 915 | 56 | 184 | 75 | 27 | 14.0 | 34.4 | 17.6 | 42.4 |

| XX-A1-3-C1A2-1200-YY | 436 | 1450 | 335 | 1289 | 400 | 1200 | 430 | 1152 | 492 | 1041 | 56 | 184 | 75 | 27 | 15.5 | 38.0 | 20.0 | 47.6 |

Note: XX-input for: RS or HRS.

YY-Input for angle: 20°, 30° , 35° ,45°

Base angle size nominated is normal stock standard.Dimensions E and F do not vary with change in base angle size.

Code numbers shown are for plain trough idlers,for impact idlers change both” A’s” in code numbers to ” B’s

GCS roller conveyor manufacturers reserves the right to change dimensions and critical data at any time without any notice. Customers must ensure that they receive certified drawings from GCS prior to finalizing design details.

Tell Us Your Requirement About Trough Idler .Contact us Now!

Related product

Rubber Disc Return Idlers

Rubber Disc Vee Return Idler by GCS Suppliers

Conveyor impact idler with rubber for mining equipment

Product detail pictures:

Related Product Guide:

We know that we only thrive if we could guarantee our combined price tag competiveness and quality advantageous at the same time for 100% Original Conveyor Rollers Heavy Duty - Trough impact roller is applied in the mine | GCS – GCS , The product will supply to all over the world, such as: Lyon, Australia, Botswana, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!