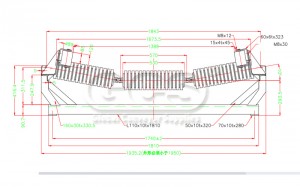

GCS Customized Degree Hinged Rubber Impact Roller Set

GCS Conveyor Supply offers a wide range of rollers to fit most conveyor applications - designed to the highest industry standards. Roller materials, lengths, diameters, and groove options can be customized to meet customer specifications. We are a manufacturer of slotted rollers, rollers, and frames. Our factory can do it all for bulk material companies, making it simple for everyone to design and order custom rollers and affordable matching roller frames online.

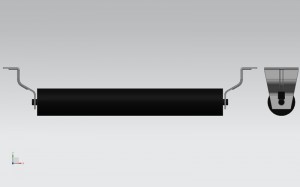

Rubber impact rollers are manufactured with steel shells and rubber discs. The impact roller is manufactured as a steel shell with surrounding rubber discs. Impact idler frames and rollers are used at conveyor loading and transfer points to reinforce against lumpy material falling from high places during transfer.

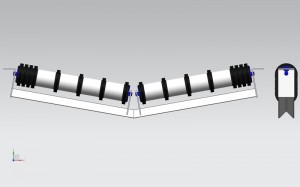

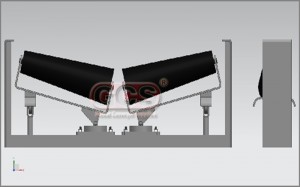

With an adjustable rubber impact roller set, two more wing rollers than conventional rubber impact roller set, so that the material is protected from falling during transfer.

Applications

Conveyor impact rollers are used for belt conveyors to receive materials and reduce and slow down the impact of the conveyor belt, mainly designed for corrosive environments such as coal washing plants, coking plants, and chemical plants. The impact rollers have good corrosion resistance and if used in corrosive situations, their service life is five times that of ordinary rollers.

10-degree hinged rubber impact roller group

Impact Troughing Idlers from GCS troughing idlers manufacturer are built with heavy-duty frames to withstand shock. GCS Impact Idlers for run out conveyor are built with heavy-duty frames to withstand shock at the loading zone.

The rubber discs used on impact idlers are made of natural molded rubber ideal for absorbing impacts and shedding sticky material.

run out conveyor

G C S conveyor roller Series

Model: RS62 63 SERIES

| Name | Belt Conveyor Impact Idler Specifications |

| Standard | DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc. |

| Shaft Diameter | 20, 25, 30, 35, 40, 45, 50mm |

| Roller Diameter | 89, 102, 108, 114, 127, 133, 140, 152, 159, 165, 178, 194, 217mm |

| Roller Length | 190-1600mm |

| Bearing brand | SKF, NSK, FAG, HRB, LYC, ZWZ, C&U |

| Color | Customized |

| BEARING | PIPE Dia |

| 6204/6205 | 60/76/89/108/114/127/133 |

| 6305/6306/6307/6308/63096310/6311/6312 | 76/89/108/114/127/133/159/165/194/219 |

RS roller is premium product with triple anti-dust structure which can effectively prevent water and dust. This model applies to the conveyor belt systems that can carry large volume and high speed dusty bulks.

Product Description

heavy duty carrying idler mining conveyor roller

Steel Return Conveyor Roller/Heavy Duty Belt Conveyor Carrying Conveyor Roller/Mining Belt Conveyor Roller Idler

Our products are widely used in thermal power generation, harbours, cement plants, metallurgy and as well as the light duty conveying devices for industries.

|

SPECIFICATIONS |

|

| Diameter | φ89, φ102, φ108, φ114, φ127, φ133, φ139, φ152, φ159, φ165, φ194 |

| Length | 145mm-2800mm |

| Tube | Q235(GB), Q345(GB), welded with DIN2394 standed |

| Shaft | A3 and 45# steel(GB) |

| Bearing | Single & Double Row Deep Groove Ball Bearing 2RS&ZZ with C3 clearance |

| Bearing Housing/Seat | Cold press working fit ISO M7 accuracy

Deep Press steel with raw material fit DIN 1623-1624 standard |

| Lubricating Oil | Grade 2 or 3 long-lasting lithium greasae |

| Welding | Mixed gas shielded arc welding end |

| Painting | Ordinary painting, hot galvanized painting, electric static spraying painting, baked painting |

| Diameter of Tube | Length of Tube | Bearing Type | |

| mm | inch |

mm |

|

| 63.5 | 2 1/2 | 150-3500 | 6204 |

| 76 | 3 | 150-3500 | 6204 6205 |

| 89 | 3 1/2 | 150-3500 | 6204 6205 |

| 102 | 4 | 150-3500 | 6204 6205 6305 |

| 108 | 4 1/4 | 150-3500 | 6204 6205 6305 6306 |

| 114 | 4 1/2 | 150-3500 | 6204 6205 6305 6306 |

| 127 | 5 | 150-3500 | 6204 6205 6305 6306 |

| 133 | 5 1/4 | 150-3500 | 6205 6206 6207 6305 6306 |

| 140 | 5 1/2 | 150-3500 | 6205 6206 6207 6305 6306 |

| 152 | 6 | 150-3500 | 6205 6206 6207 6305 6306 6307 6308 |

| 159 | 6 1/4 | 150-3500 | 6205 6206 6207 6305 6306 6307 6308 |

| 165 | 6 1/2 | 150-3500 | 6207 6305 6306 6307 6308 |

| 177.8 | 7 | 150-3500 | 6207 6306 6307 6308 6309 |

| 190.5 | 7 1/2 | 150-3500 | 6207 6306 6307 6308 6309 |

| 194 | 7 5/8 | 150-3500 | 6207 6307 6308 6309 6310 |

| 219 | 8 5/8 | 150-3500 | 6308 6309 6310 |

About roller,we can make gravity conveyor roller,steel conveyor roller,driving roller,light middle duty conveyor roller,o-belt tapered sleeve roller,gravity tapered roller,polymer sprocket roller and so on.More details,please contact us.

|

Basic Info. |

|

| Model NO. | NS/RS/LS |

| Surface Finishing | Painting, Galvanized or as Your Demand |

| Length | 200-2800mm |

| Colour | as Your Requirement |

| Import Bearings | Lyc(China Famous)NSK, SKF |

| Standard | ISO, Cema, DIN |

| Certification | ISO9001:2015 |

| Ctructure | Conveyor Roller |

| Idler Diameter | 89,108,133,159,194,219mm |

| Color | as Per Your Request |

| Features | Durable ,Power Saving ,etc. |

| Material Feature | Durable |

| After-Sales Service | Engineers Available to Service Machinery Overseas |

| Load Capacity | as Per Order |

| Packaging Details | Wooden Case, Pallet Packaging, Standard Packaging |

| Trademark | GCS, GCS |

| Transport Package | Wooden Box |

| Specification | Customers′ Requirements |

| Origin | Guangdong, China (Mainland) |

| HS Code | 8431390000 |

Roller Idler Application

GCS Conveyor Roller products are widely used in thermal power generation, harbours, cement plants, metallurgy and as well as the light duty conveying devices for industries.

v roller conveyor

Mining Conveyor

Video

Belt Conveyor Roller Idler

Introduction conveyor roller in conveyor

More details,please contact us.

1.What is rubber umpact roller?

Impact roller applies mechanical energy used to reduce air voids and rearrange soil particles to increase density.

2.What is roller conveyor system?

A Belt conveyor is a necessary equipment for crushing and construction waste production lines. You can refer to What is roller conveyor system?

3.Why choose roller conveyor?

The main advantages are adjustable height and inclination. Choosing roller conveyor can reduce the cost. More reference in Why choose roller conveyor?